gas utilization equipment in the area. If you are unsure that the structure meets this requirement, contact your local gas utility company or other qualified agency for a safety inspection.

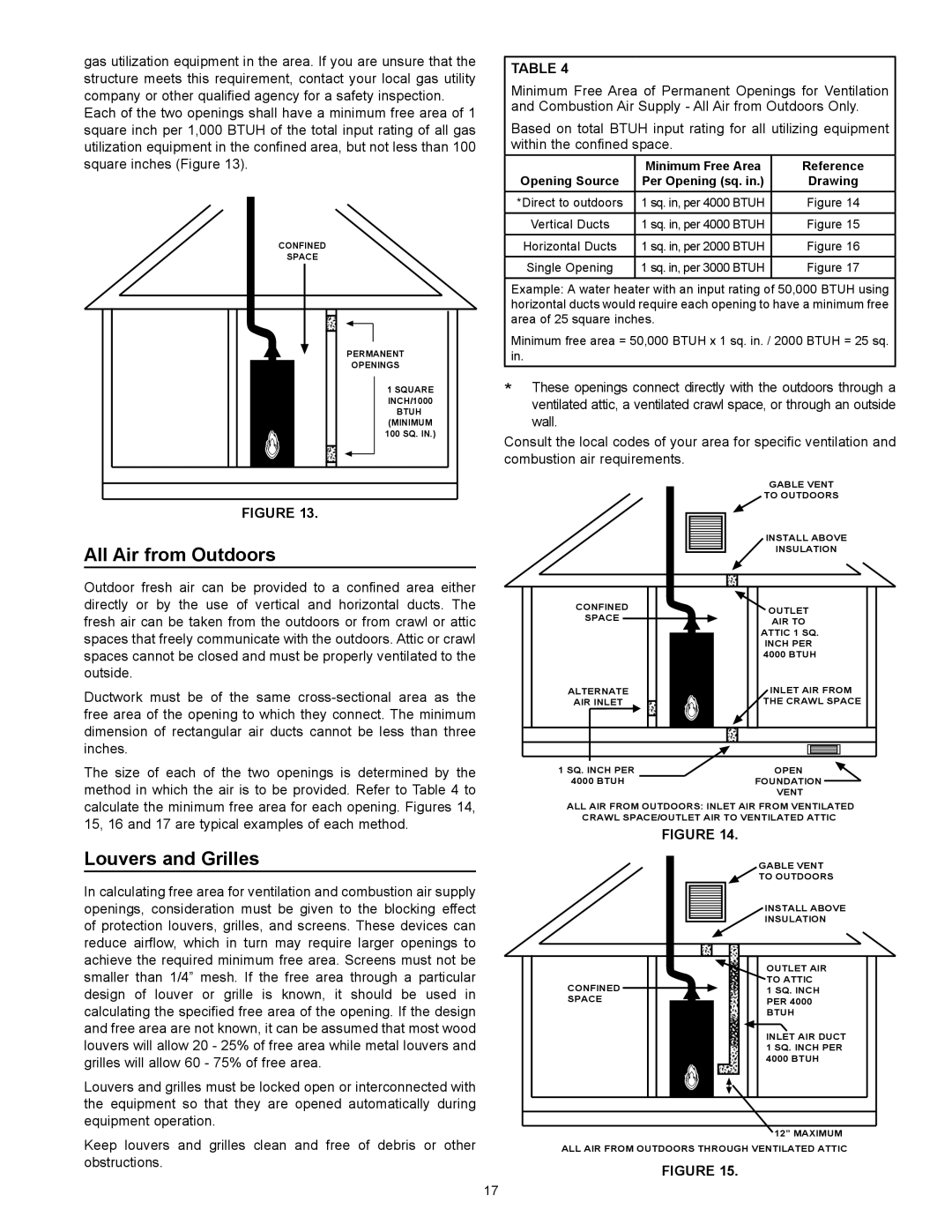

Each of the two openings shall have a minimum free area of 1 square inch per 1,000 BTUH of the total input rating of all gas utilization equipment in the confined area, but not less than 100 square inches (Figure 13).

CONFINED |

SPACE |

PERMANENT |

OPENINGS |

1 SQUARE |

INCH/1000 |

BTUH |

(MINIMUM |

100 SQ. IN.) |

FIGURE 13.

All Air from Outdoors

Outdoor fresh air can be provided to a confined area either directly or by the use of vertical and horizontal ducts. The fresh air can be taken from the outdoors or from crawl or attic spaces that freely communicate with the outdoors. Attic or crawl spaces cannot be closed and must be properly ventilated to the outside.

Ductwork must be of the same

The size of each of the two openings is determined by the method in which the air is to be provided. Refer to Table 4 to calculate the minimum free area for each opening. Figures 14, 15, 16 and 17 are typical examples of each method.

Louvers and Grilles

In calculating free area for ventilation and combustion air supply openings, consideration must be given to the blocking effect of protection louvers, grilles, and screens. These devices can reduce airflow, which in turn may require larger openings to achieve the required minimum free area. Screens must not be smaller than 1/4” mesh. If the free area through a particular design of louver or grille is known, it should be used in calculating the specified free area of the opening. If the design and free area are not known, it can be assumed that most wood louvers will allow 20 - 25% of free area while metal louvers and grilles will allow 60 - 75% of free area.

Louvers and grilles must be locked open or interconnected with the equipment so that they are opened automatically during equipment operation.

Keep louvers and grilles clean and free of debris or other obstructions.

TABLE 4

Minimum Free Area of Permanent Openings for Ventilation and Combustion Air Supply - All Air from Outdoors Only.

Based on total BTUH input rating for all utilizing equipment within the confined space.

| Minimum Free Area | Reference |

Opening Source | Per Opening (sq. in.) | Drawing |

*Direct to outdoors | 1 sq. in, per 4000 BTUH | Figure 14 |

Vertical Ducts | 1 sq. in, per 4000 BTUH | Figure 15 |

Horizontal Ducts | 1 sq. in, per 2000 BTUH | Figure 16 |

Single Opening | 1 sq. in, per 3000 BTUH | Figure 17 |

|

|

|

Example: A water heater with an input rating of 50,000 BTUH using horizontal ducts would require each opening to have a minimum free area of 25 square inches.

Minimum free area = 50,000 BTUH x 1 sq. in. / 2000 BTUH = 25 sq. in.

*These openings connect directly with the outdoors through a ventilated attic, a ventilated crawl space, or through an outside wall.

Consult the local codes of your area for specific ventilation and combustion air requirements.

| GABLE VENT | |

| TO OUTDOORS | |

| INSTALL ABOVE | |

| INSULATION | |

CONFINED | OUTLET | |

SPACE | ||

AIR TO | ||

| ATTIC 1 SQ. | |

| INCH PER | |

| 4000 BTUH |

| ALTERNATE |

|

|

|

|

| INLET AIR FROM | |||||

| AIR INLET |

|

|

|

|

| THE CRAWL SPACE | |||||

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1 SQ. INCH PER |

|

|

|

|

| OPEN | |||||

| 4000 BTUH |

|

|

|

|

| FOUNDATION |

|

| |||

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

| VENT | ||||

ALL AIR FROM OUTDOORS: INLET AIR FROM VENTILATED

CRAWL SPACE/OUTLET AIR TO VENTILATED ATTIC

FIGURE 14.

| GABLE VENT |

| TO OUTDOORS |

| INSTALL ABOVE |

| INSULATION |

| OUTLET AIR |

CONFINED | TO ATTIC |

1 SQ. INCH | |

SPACE | PER 4000 |

| BTUH |

INLET AIR DUCT 1 SQ. INCH PER 4000 BTUH

12” MAXIMUM ALL AIR FROM OUTDOORS THROUGH VENTILATED ATTIC

FIGURE 15.

17