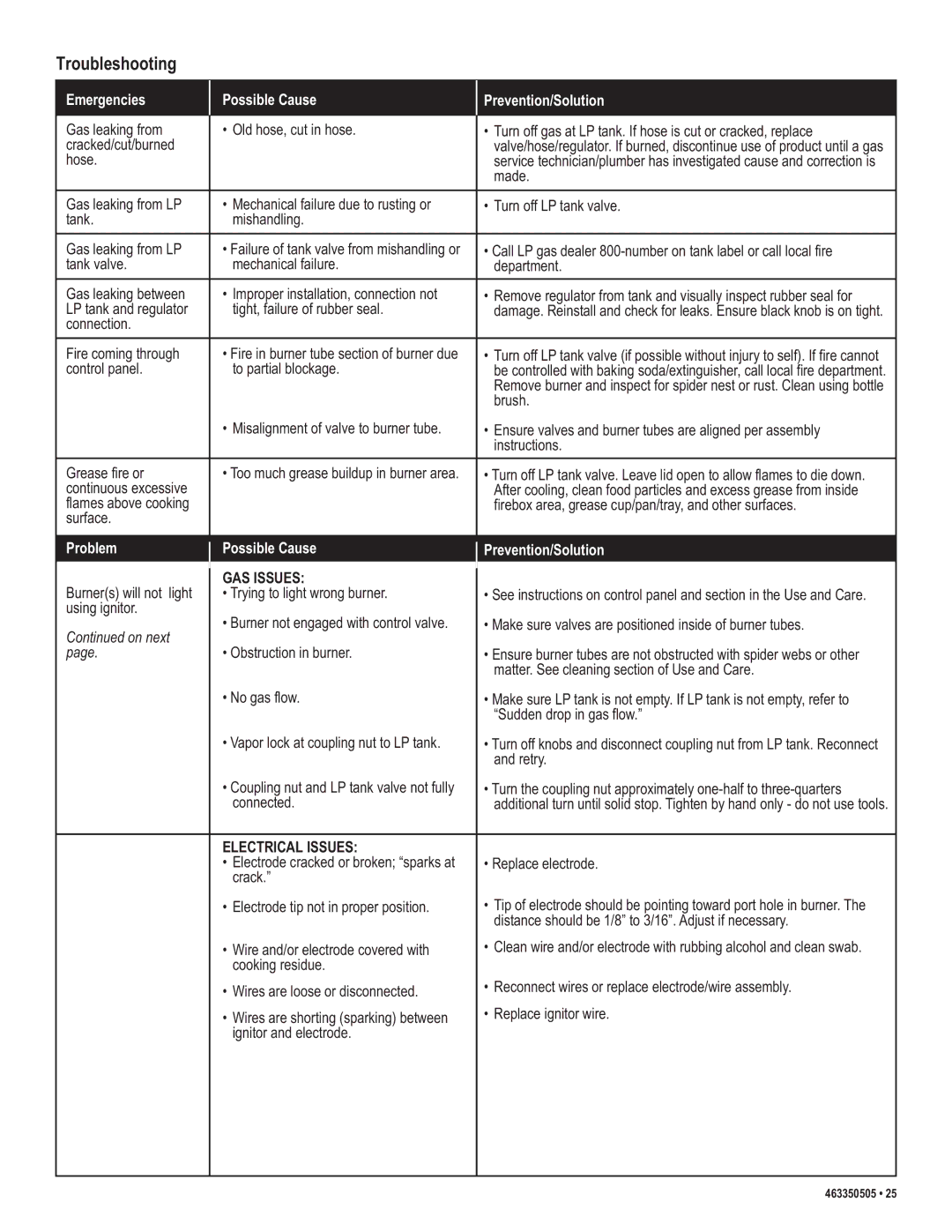

Troubleshooting

Emergencies | Possible Cause | Prevention/Solution |

|

|

|

Gas leaking from | • Old hose, cut in hose. | • Turn off gas at LP tank. If hose is cut or cracked, replace |

cracked/cut/burned |

| valve/hose/regulator. If burned, discontinue use of product until a gas |

hose. |

| service technician/plumber has investigated cause and correction is |

|

| made. |

|

|

|

Gas leaking from LP | • Mechanical failure due to rusting or | • Turn off LP tank valve. |

tank. | mishandling. |

|

|

|

|

Gas leaking from LP | • Failure of tank valve from mishandling or | • Call LP gas dealer |

tank valve. | mechanical failure. | department. |

|

|

|

Gas leaking between | • Improper installation, connection not | • Remove regulator from tank and visually inspect rubber seal for |

LP tank and regulator | tight, failure of rubber seal. | damage. Reinstall and check for leaks. Ensure black knob is on tight. |

connection. |

|

|

|

|

|

Fire coming through | • Fire in burner tube section of burner due | • Turn off LP tank valve (if possible without injury to self). If fire cannot |

control panel. | to partial blockage. | be controlled with baking soda/extinguisher, call local fire department. |

|

| Remove burner and inspect for spider nest or rust. Clean using bottle |

|

| brush. |

| • Misalignment of valve to burner tube. | • Ensure valves and burner tubes are aligned per assembly |

|

| instructions. |

|

|

|

Grease fire or | • Too much grease buildup in burner area. | • Turn off LP tank valve. Leave lid open to allow flames to die down. |

continuous excessive |

| After cooling, clean food particles and excess grease from inside |

flames above cooking |

| firebox area, grease cup/pan/tray, and other surfaces. |

surface. |

|

|

Problem | Possible Cause | Prevention/Solution |

| GAS ISSUES: |

|

Burner(s) will not light | • Trying to light wrong burner. | • See instructions on control panel and section in the Use and Care. |

using ignitor. |

|

|

Continued on next | • Burner not engaged with control valve. | • Make sure valves are positioned inside of burner tubes. |

|

| |

page. | • Obstruction in burner. | • Ensure burner tubes are not obstructed with spider webs or other |

|

| matter. See cleaning section of Use and Care. |

| • No gas flow. | • Make sure LP tank is not empty. If LP tank is not empty, refer to |

|

| “Sudden drop in gas flow.” |

| • Vapor lock at coupling nut to LP tank. | • Turn off knobs and disconnect coupling nut from LP tank. Reconnect |

|

| and retry. |

| • Coupling nut and LP tank valve not fully | • Turn the coupling nut approximately |

| connected. | additional turn until solid stop. Tighten by hand only - do not use tools. |

ELECTRICAL ISSUES: |

|

• Electrode cracked or broken; “sparks at | • Replace electrode. |

crack.” |

|

• Electrode tip not in proper position. | • Tip of electrode should be pointing toward port hole in burner. The |

| distance should be 1/8” to 3/16”. Adjust if necessary. |

• Wire and/or electrode covered with | • Clean wire and/or electrode with rubbing alcohol and clean swab. |

cooking residue. |

|

• Wires are loose or disconnected. | • Reconnect wires or replace electrode/wire assembly. |

| |

• Wires are shorting (sparking) between | • Replace ignitor wire. |

| |

ignitor and electrode. |

|

463350505 • 25