STORAGE

For consistent results, all aerial films should be stored under fairly constant conditions. Kodak aerial films are “usually” packaged in equilibrium with 40 to 50 percent relative humidity. High temperatures or high humidity may produce undesirable changes in the film.

Unexposed Film

Store unexposed film in a refrigerator at 55°F (13°C) or lower, or freezer at 0 to

Exposed Film

Keep exposed film cool and dry. Process the film as soon as possible after exposure to avoid undesirable changes in the latent image. If it is necessary to hold exposed but unprocessed film for several days (such as over a weekend), it should be resealed and refrigerated at 40°F (4°C) or lower. Before unsealing and processing exposed film that has been held in cold storage, follow the

Processed Film

For best keeping, store processed film in a dark,

PROCESSING

The primary recommendation for processing 2427 Film is in Process

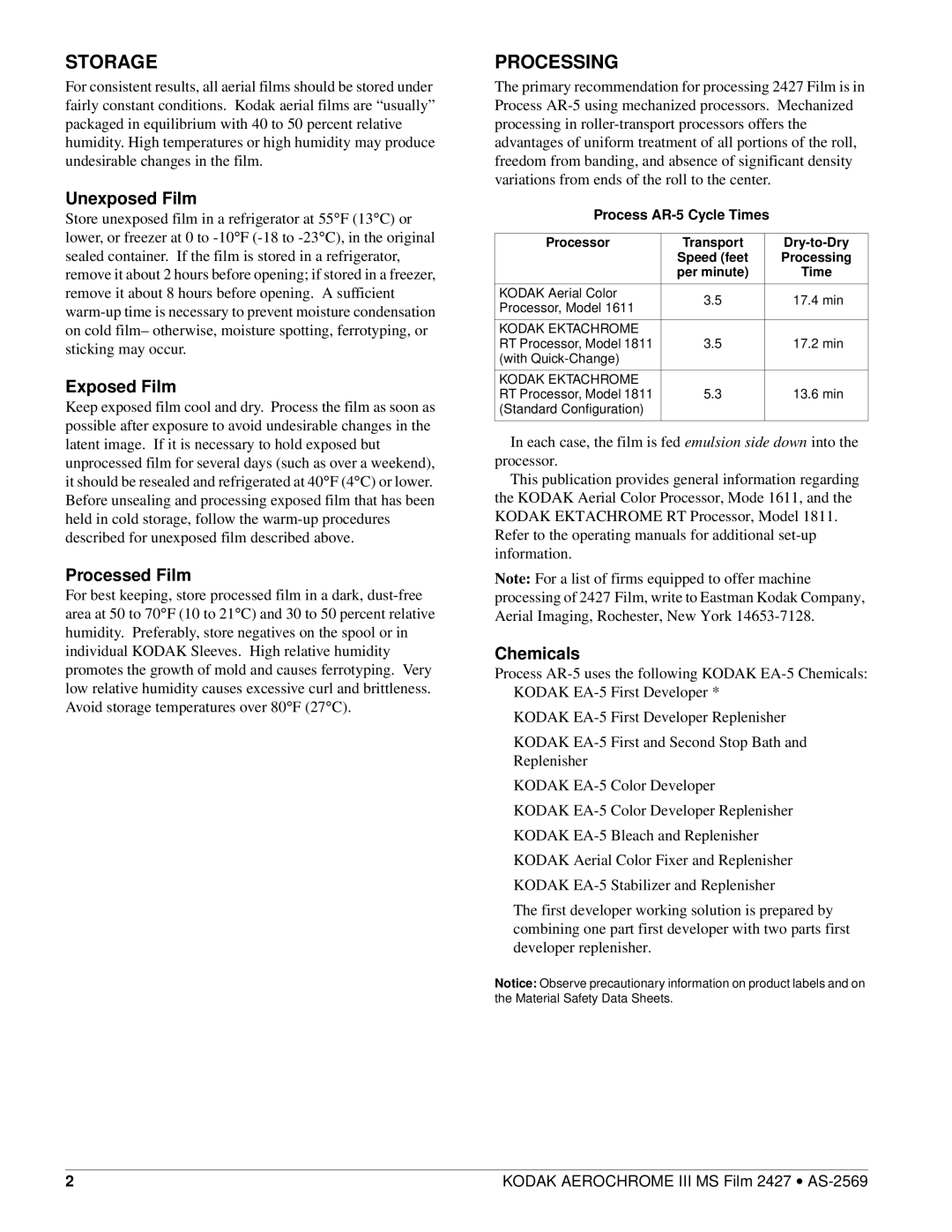

Process AR-5 Cycle Times

Processor | Transport |

| |

| Speed (feet | Processing | |

| per minute) | Time | |

|

|

| |

KODAK Aerial Color | 3.5 | 17.4 min | |

Processor, Model 1611 | |||

|

| ||

|

|

| |

KODAK EKTACHROME |

|

| |

RT Processor, Model 1811 | 3.5 | 17.2 min | |

(with |

|

| |

|

|

| |

KODAK EKTACHROME |

|

| |

RT Processor, Model 1811 | 5.3 | 13.6 min | |

(Standard Configuration) |

|

| |

|

|

|

In each case, the film is fed emulsion side down into the processor.

This publication provides general information regarding the KODAK Aerial Color Processor, Mode 1611, and the KODAK EKTACHROME RT Processor, Model 1811. Refer to the operating manuals for additional

Note: For a list of firms equipped to offer machine processing of 2427 Film, write to Eastman Kodak Company, Aerial Imaging, Rochester, New York

Chemicals

Process

KODAK

KODAK

KODAK

KODAK

KODAK

KODAK Aerial Color Fixer and Replenisher

KODAK

The first developer working solution is prepared by combining one part first developer with two parts first developer replenisher.

Notice: Observe precautionary information on product labels and on the Material Safety Data Sheets.

2 | KODAK AEROCHROME III MS Film 2427 • |