LARGE PHOTOGRAPHIC PROCESSING FACILITIES

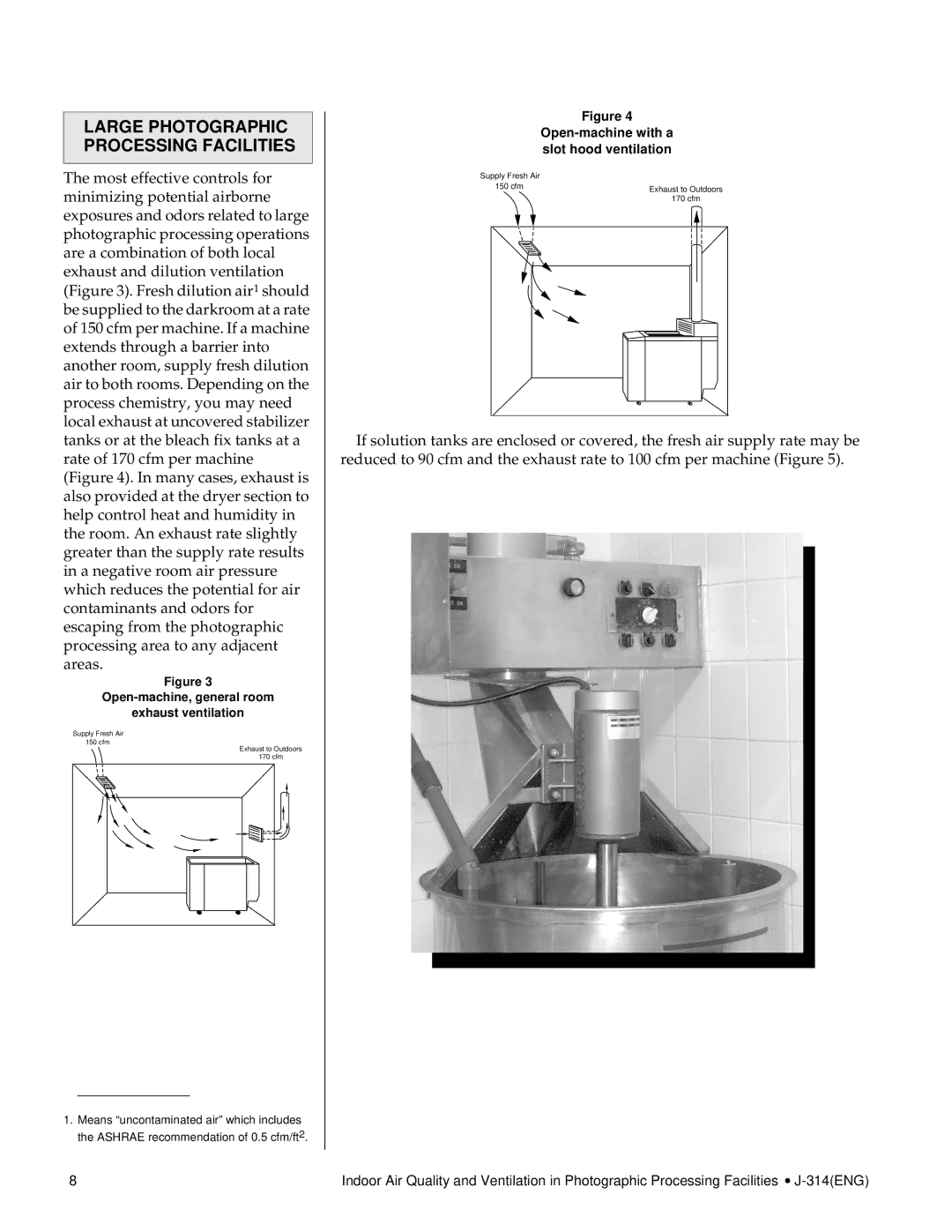

The most effective controls for minimizing potential airborne exposures and odors related to large photographic processing operations are a combination of both local exhaust and dilution ventilation (Figure 3). Fresh dilution air1 should be supplied to the darkroom at a rate of 150 cfm per machine. If a machine extends through a barrier into another room, supply fresh dilution air to both rooms. Depending on the process chemistry, you may need local exhaust at uncovered stabilizer tanks or at the bleach fix tanks at a rate of 170 cfm per machine (Figure 4). In many cases, exhaust is also provided at the dryer section to help control heat and humidity in the room. An exhaust rate slightly greater than the supply rate results in a negative room air pressure which reduces the potential for air contaminants and odors for escaping from the photographic processing area to any adjacent areas.

Figure 3

Open-machine, general room

exhaust ventilation

Supply Fresh Air

150 cfm

Exhaust to Outdoors

170 cfm

1.Means “uncontaminated air” which includes the ASHRAE recommendation of 0.5 cfm/ft2.

Figure 4

Open-machine with a slot hood ventilation

Supply Fresh Air |

|

| |

150 cfm | Exhaust to Outdoors | ||

|

| ||

|

| 170 cfm | |

|

|

|

|

|

|

|

|

If solution tanks are enclosed or covered, the fresh air supply rate may be reduced to 90 cfm and the exhaust rate to 100 cfm per machine (Figure 5).

8 | Indoor Air Quality and Ventilation in Photographic Processing Facilities • |