5100TK OPR 6270US R060106

MIXER OPERATION

Always refer to Operating Safety Precautions and Safety Decal sections of this manual before operating this mixer.

KNIFE ADJUSTMENT

The Vertical Maxx Mixer is designed and intended for processing and mixing rations that include long stem forages. In most cases, the knives that come standard on the mixer are placed to work well in most rations. However, some rations may require adding or removing knives to obtain the desired result.

REMOVING KNIVES

Individual knives may be removed from the auger if the ration does not include hay, or includes very small amounts of small square bale hay or tub ground hay. Removing knives will decrease the aggressive cutting action on the stem length of the ration and may also reduce horse power requirements.

ADDING KNIVES

If the hay in your ration is not being processed enough or fast enough, extra knives and backers may be ordered through your dealer. Adding extra knives will help break down and process materials faster, but may increase the horsepower required to process and mix.

The placement of knives towards the bottom of the auger will process the forage faster and make stem the length shorter, but may require more horsepower. Placement of knives higher on the auger will assist in breaking up bales faster after initial loading.

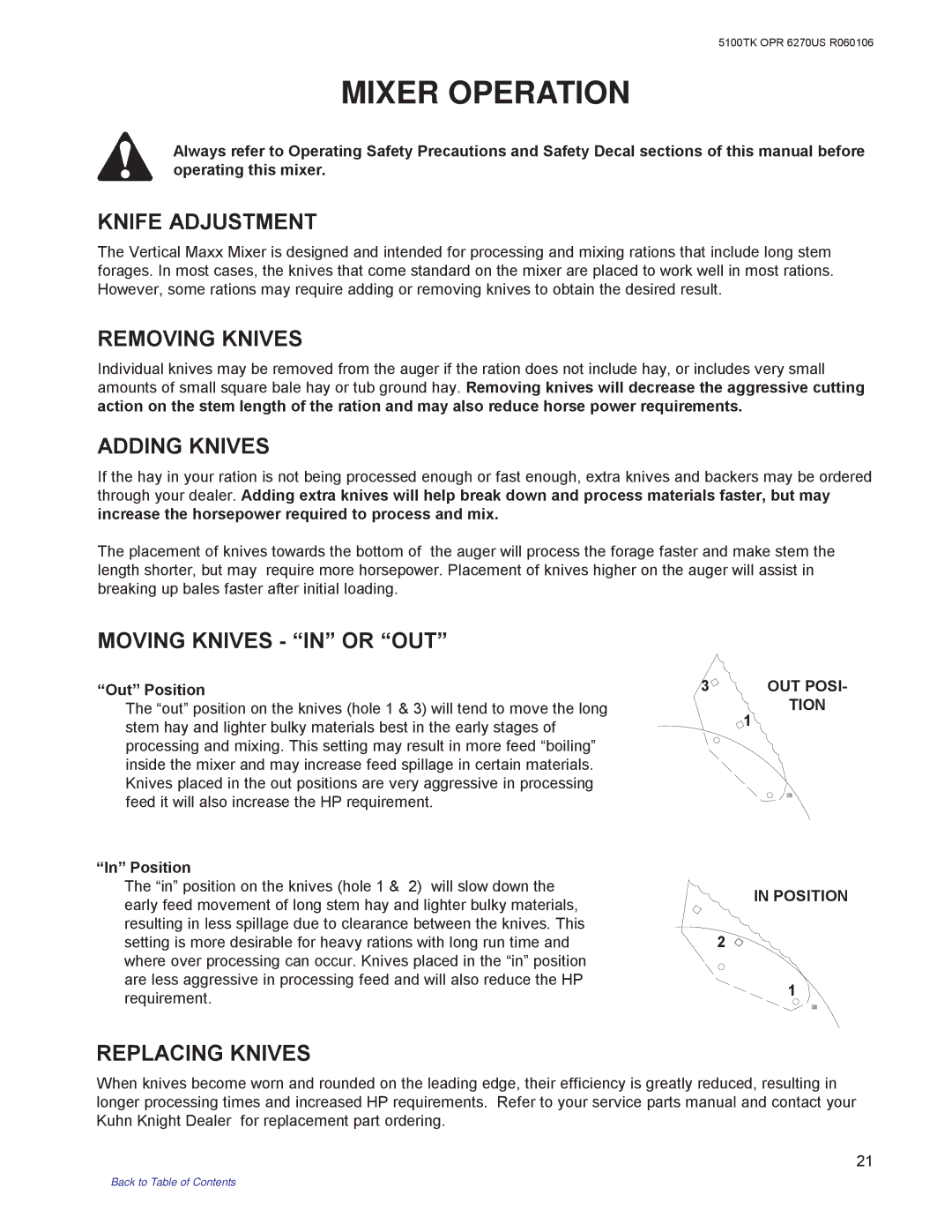

MOVING KNIVES - “IN” OR “OUT”

“Out” Position | 3 | OUT POSI- |

|

| |

The “out” position on the knives (hole 1 & 3) will tend to move the long |

| TION |

| 1 | |

stem hay and lighter bulky materials best in the early stages of |

| |

|

| |

processing and mixing. This setting may result in more feed “boiling” |

|

|

inside the mixer and may increase feed spillage in certain materials. |

|

|

Knives placed in the out positions are very aggressive in processing |

|

|

feed it will also increase the HP requirement. |

|

|

“In” Position

The “in” position on the knives (hole 1 & 2) will slow down the early feed movement of long stem hay and lighter bulky materials, resulting in less spillage due to clearance between the knives. This setting is more desirable for heavy rations with long run time and where over processing can occur. Knives placed in the “in” position are less aggressive in processing feed and will also reduce the HP requirement.

IN POSITION

2

1

REPLACING KNIVES

When knives become worn and rounded on the leading edge, their efficiency is greatly reduced, resulting in longer processing times and increased HP requirements. Refer to your service parts manual and contact your Kuhn Knight Dealer for replacement part ordering.

21

Back to Table of Contents