5100TK OPR 6270US R060106

MAINTENANCE

Always stop mixer, shut off tractor engine and remove the PTO driveline before servicing, repairing or cleaning the machine.

If work must be done inside the mixer, put a protective cover over the auger knives to avoid injury. The hopper floor and fighting may be slippery. Use caution when stepping on or standing inside the machine.

Use safe shop procedures and exercise caution when working on the mixer!

MISCELLANEOUS

ELECTRONIC SCALE INDICATOR (OPTIONAL)

Refer to the electronic scale operators manual for adjustment information. The operator’s manual for the Electronic Scales should be kept with this manual. Additional scale manuals may be obtained through Kuhn Knight, Inc.

Normal scale activity: Some warm up scale drift may occur after the scale is turned on but should zero balance within

OIL QUALITY IN BULL GEAR OIL BATH

It is normal for the oil in the oil bath to have some water present, due to condensation. This will cause the oil to have a milky appearance, and a moderate amount of water does not effect the lubricating characteristics of the oil. See lubrication section for oil change intervals.

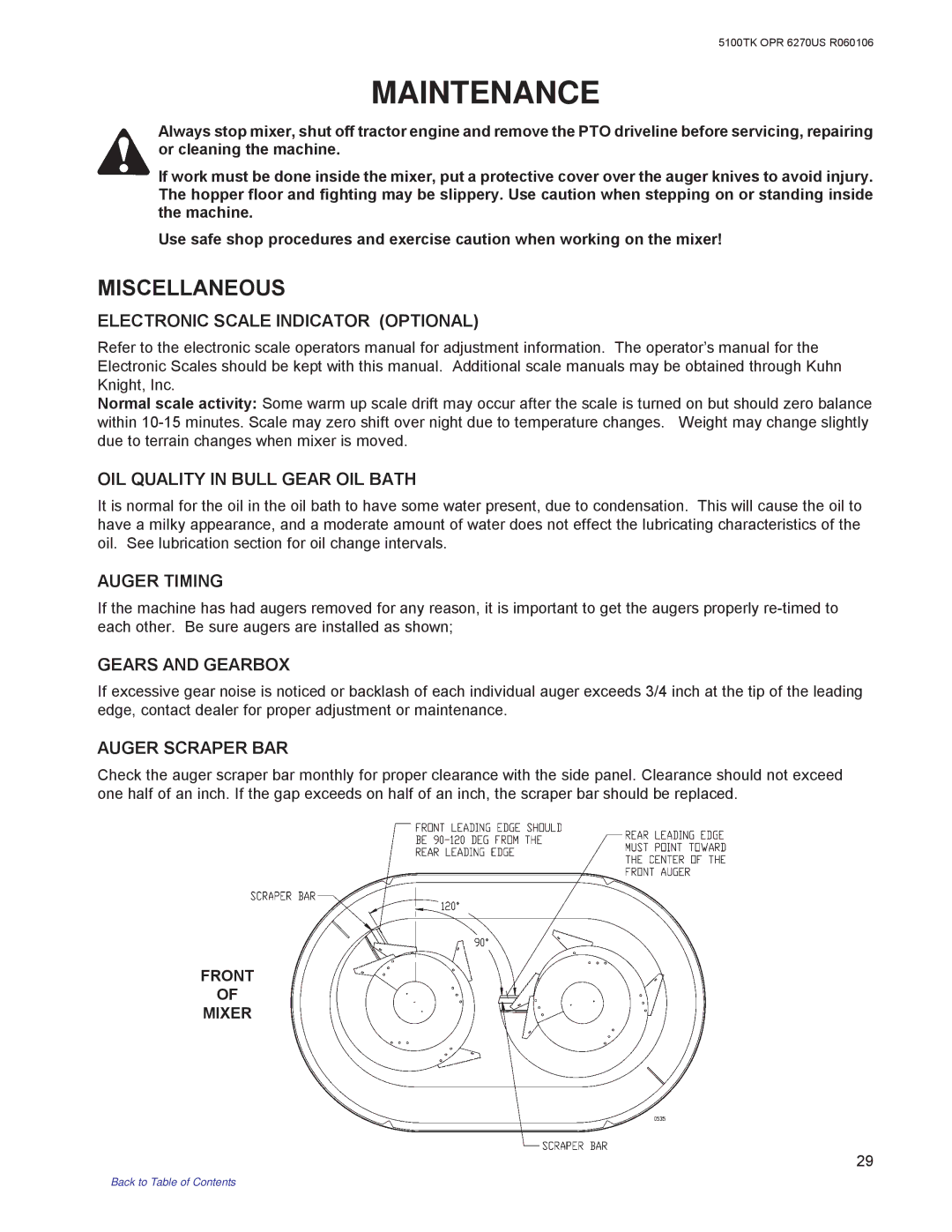

AUGER TIMING

If the machine has had augers removed for any reason, it is important to get the augers properly

GEARS AND GEARBOX

If excessive gear noise is noticed or backlash of each individual auger exceeds 3/4 inch at the tip of the leading edge, contact dealer for proper adjustment or maintenance.

AUGER SCRAPER BAR

Check the auger scraper bar monthly for proper clearance with the side panel. Clearance should not exceed one half of an inch. If the gap exceeds on half of an inch, the scraper bar should be replaced.

FRONT

OF

MIXER

29

Back to Table of Contents