INSTALLATION

TECHNICALINFORMATION

FORTHEINSTALLER

Installation, adjustments of controls and maintenance must only be carried out by a qualifiedengineer.

Incorrect installation may cause damage to persons, animals or property for which the Manufacturershallnotbeconsideredresponsible. During the life of the system, the automatic safety or regulating devices on the appliance may only be modified by the manufacturer or by hisdulyauthorizeddealer.

4)INSTALLINGTHEWORKTOP

Check that the appliance is in a good condition after having removed the outer packaging and internal wrappings from around the various loose parts. In case of doubt, do not use the appliance and contact qualified personnel.

Neverleavethepackagingmaterials(cardboard, bags, polystyrene foam, nails, etc.) within children’s reach since they could become potentialsourcesofdanger.

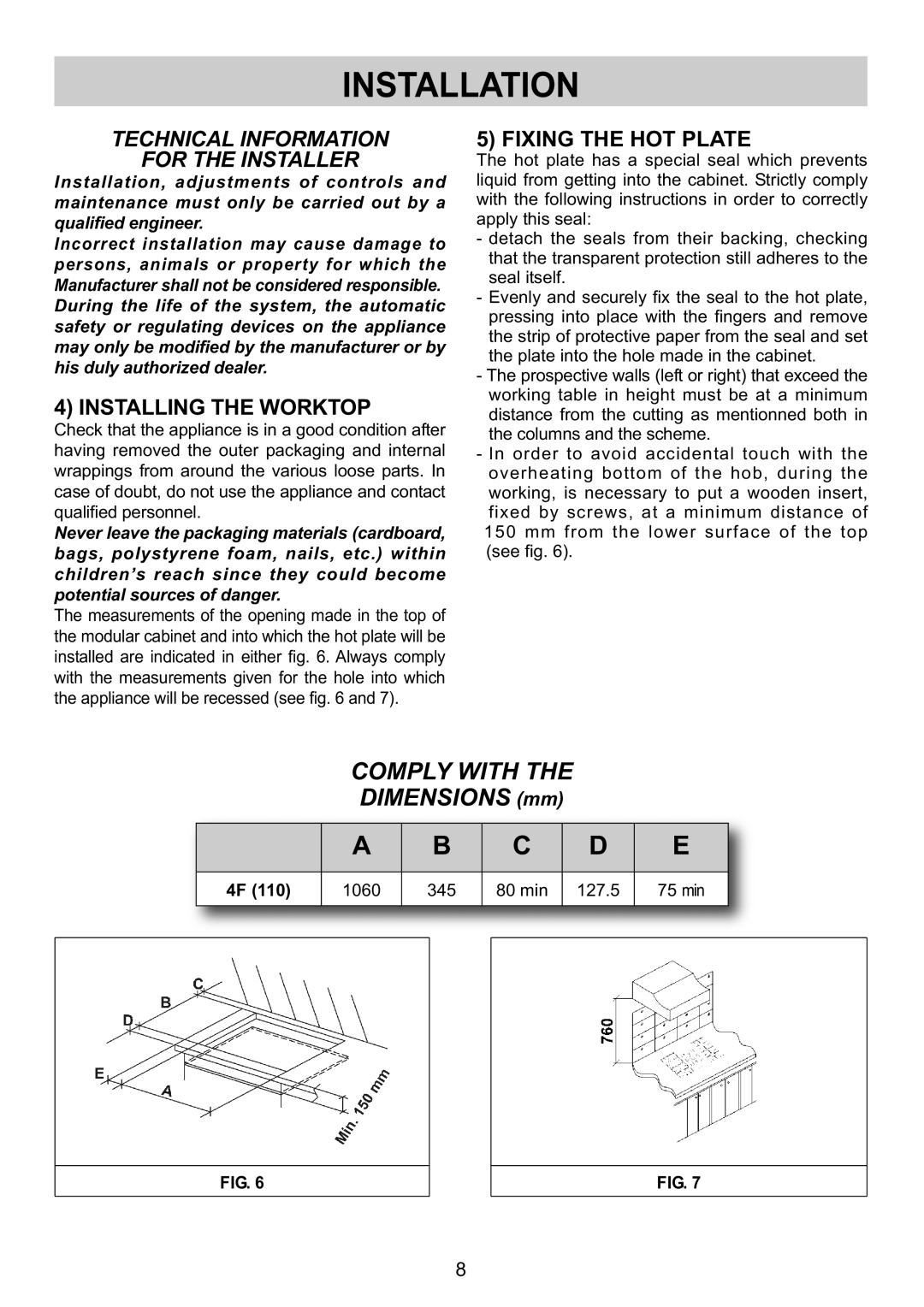

The measurements of the opening made in the top of themodularcabinetandintowhichthehotplatewillbe installed are indicated in either fig. 6. Always comply with the measurements given for the hole into which theappliancewillberecessed(seefig.6and7).

5) FIXING THE HOT PLATE

The hot plate has a special seal which prevents liquid from getting into the cabinet. Strictly comply with the following instructions in order to correctly apply this seal:

- detach the seals from their backing, checking that the transparent protection still adheres to the seal itself.

- Evenly and securely fix the seal to the hot plate, pressing into place with the fingers and remove the strip of protective paper from the seal and set the plate into the hole made in the cabinet.

- The prospective walls (left or right) that exceed the working table in height must be at a minimum distance from the cutting as mentionned both in the columns and the scheme.

- In order to avoid accidental touch with the overheating bottom of the hob, during the working, is necessary to put a wooden insert, fixed by screws, at a minimum distance of 150 mm from the lower surface of the top (see fig. 6).

COMPLY WITH THE DIMENSIONS(mm)

A B

4F(110) 1060 345

C | D | E |

80 min | 127.5 | 75 min |

FIG.6

FIG.7

8