Land Pride

Section 2: Adjustments

Table of Contents

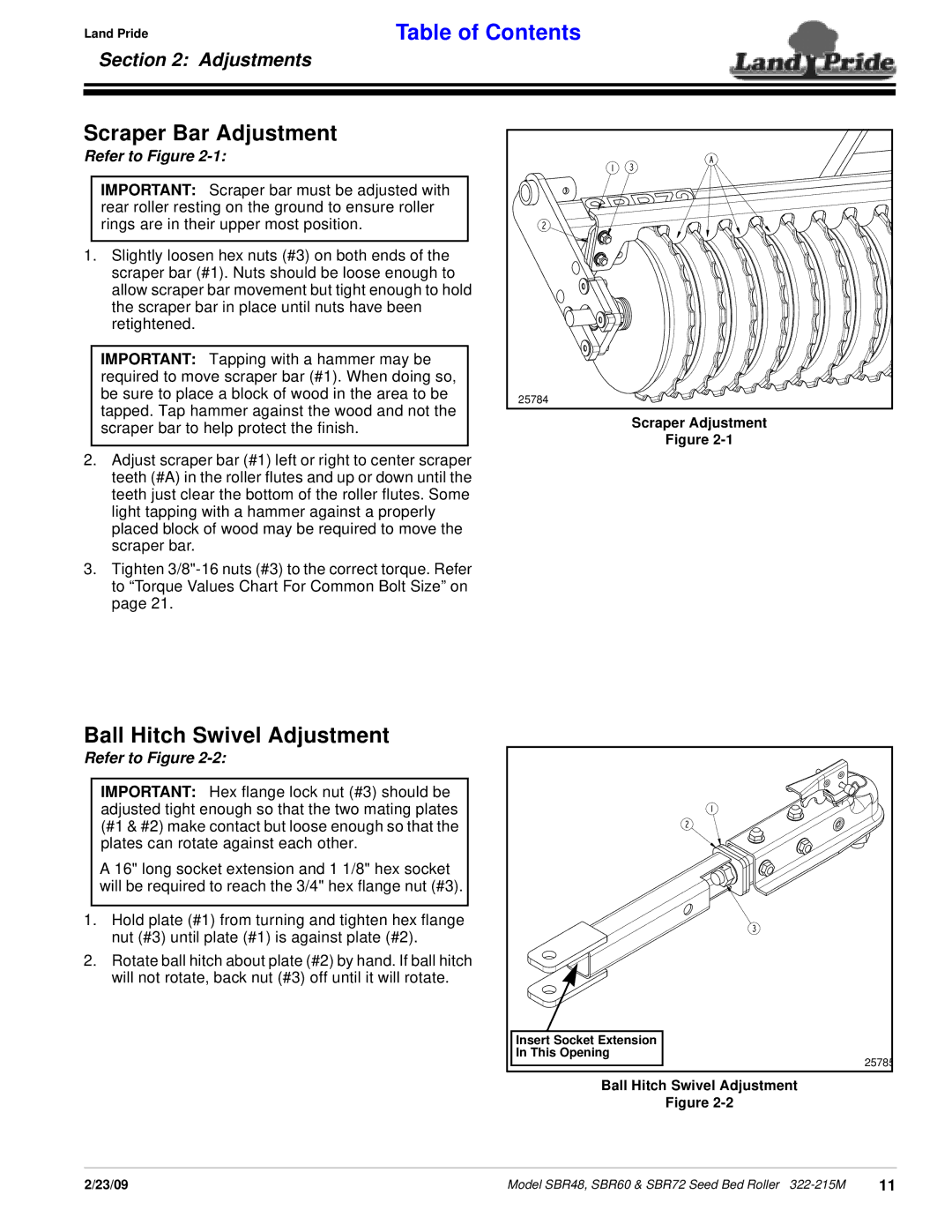

Scraper Bar Adjustment

Refer to Figure 2-1:

IMPORTANT: Scraper bar must be adjusted with rear roller resting on the ground to ensure roller rings are in their upper most position.

1.Slightly loosen hex nuts (#3) on both ends of the scraper bar (#1). Nuts should be loose enough to allow scraper bar movement but tight enough to hold the scraper bar in place until nuts have been retightened.

IMPORTANT: Tapping with a hammer may be required to move scraper bar (#1). When doing so, be sure to place a block of wood in the area to be tapped. Tap hammer against the wood and not the scraper bar to help protect the finish.

25784 |

Scraper Adjustment

Figure

2.Adjust scraper bar (#1) left or right to center scraper teeth (#A) in the roller flutes and up or down until the teeth just clear the bottom of the roller flutes. Some light tapping with a hammer against a properly placed block of wood may be required to move the scraper bar.

3.Tighten

Ball Hitch Swivel Adjustment

Refer to Figure 2-2:

IMPORTANT: Hex flange lock nut (#3) should be adjusted tight enough so that the two mating plates (#1 & #2) make contact but loose enough so that the plates can rotate against each other.

A 16" long socket extension and 1 1/8" hex socket will be required to reach the 3/4" hex flange nut (#3).

1.Hold plate (#1) from turning and tighten hex flange nut (#3) until plate (#1) is against plate (#2).

2.Rotate ball hitch about plate (#2) by hand. If ball hitch will not rotate, back nut (#3) off until it will rotate.

Insert Socket Extension |

In This Opening |

25785 |

Ball Hitch Swivel Adjustment

Figure

2/23/09 | Model SBR48, SBR60 & SBR72 Seed Bed Roller | 11 |