Table of Contents

Section 3: Operating Procedures

Land Pride

Operating Check List

Hazard control and accident prevention are dependent upon the awareness, concern, prudence and proper training involved in the operation, transport, maintenance and storage of the Seed Bed Roller. Therefore, it is absolutely essential that no one operates the roller without first having read, fully understood and become totally familiar with the Operator’s Manual. Make sure the operator has paid particular attention to:

•Important Safety Information, pages 1 to 4

•Section 1: Assembly &

•Section 2: Adjustments, page 11

•Section 3: Operating Procedures, page 12

•Section 4: Maintenance & Lubrication, page 16

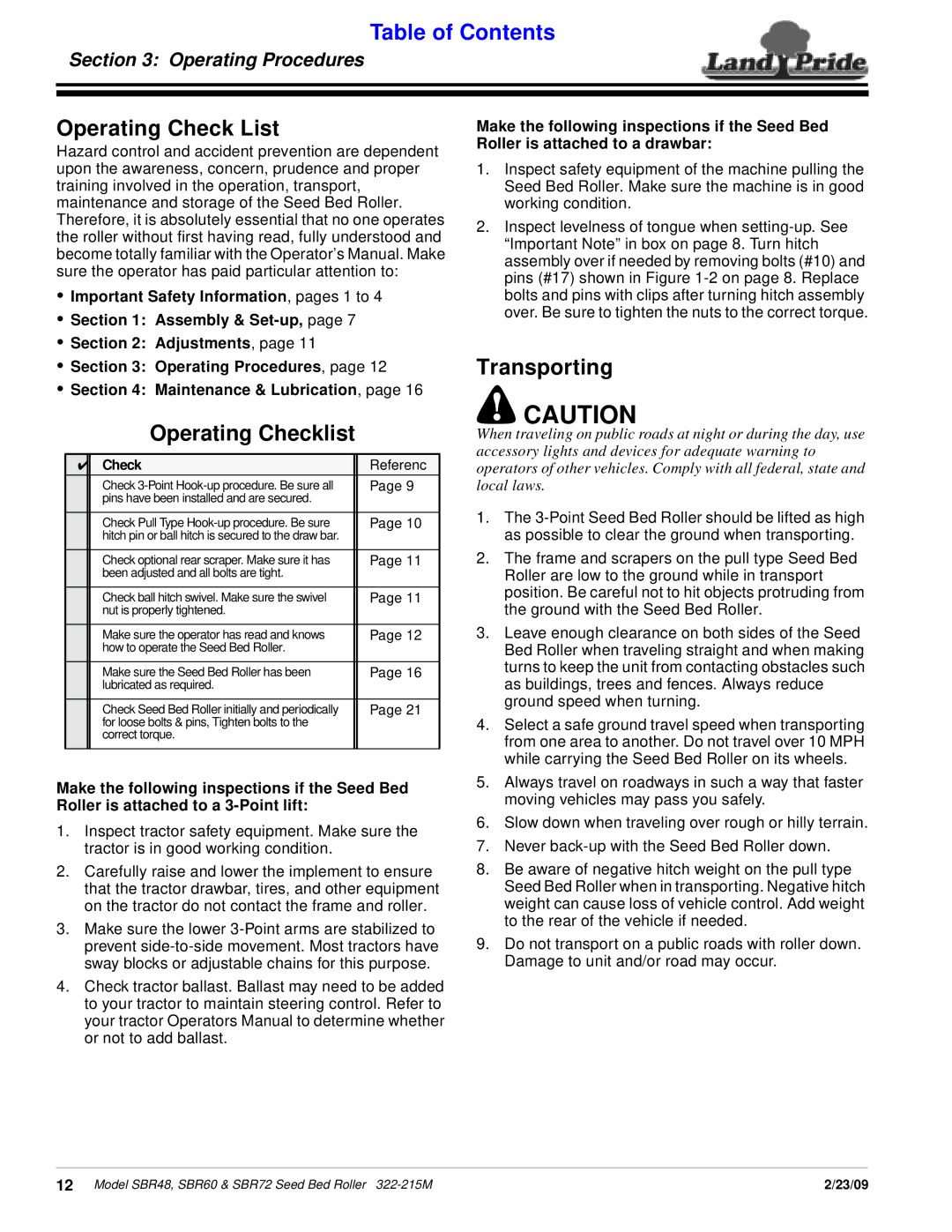

Operating Checklist

✔ | Check | Referenc |

| Check | Page 9 |

| pins have been installed and are secured. |

|

|

|

|

| Check Pull Type | Page 10 |

| hitch pin or ball hitch is secured to the draw bar. |

|

|

|

|

| Check optional rear scraper. Make sure it has | Page 11 |

| been adjusted and all bolts are tight. |

|

|

|

|

| Check ball hitch swivel. Make sure the swivel | Page 11 |

| nut is properly tightened. |

|

|

|

|

| Make sure the operator has read and knows | Page 12 |

| how to operate the Seed Bed Roller. |

|

|

|

|

| Make sure the Seed Bed Roller has been | Page 16 |

| lubricated as required. |

|

|

|

|

| Check Seed Bed Roller initially and periodically | Page 21 |

| for loose bolts & pins, Tighten bolts to the |

|

| correct torque. |

|

|

|

|

Make the following inspections if the Seed Bed Roller is attached to a drawbar:

1.Inspect safety equipment of the machine pulling the Seed Bed Roller. Make sure the machine is in good working condition.

2.Inspect levelness of tongue when

Transporting

!CAUTION

When traveling on public roads at night or during the day, use accessory lights and devices for adequate warning to operators of other vehicles. Comply with all federal, state and local laws.

1.The

2.The frame and scrapers on the pull type Seed Bed Roller are low to the ground while in transport position. Be careful not to hit objects protruding from the ground with the Seed Bed Roller.

3.Leave enough clearance on both sides of the Seed Bed Roller when traveling straight and when making turns to keep the unit from contacting obstacles such as buildings, trees and fences. Always reduce ground speed when turning.

4.Select a safe ground travel speed when transporting from one area to another. Do not travel over 10 MPH while carrying the Seed Bed Roller on its wheels.

Make the following inspections if the Seed Bed Roller is attached to a

1.Inspect tractor safety equipment. Make sure the tractor is in good working condition.

2.Carefully raise and lower the implement to ensure that the tractor drawbar, tires, and other equipment on the tractor do not contact the frame and roller.

3.Make sure the lower

4.Check tractor ballast. Ballast may need to be added to your tractor to maintain steering control. Refer to your tractor Operators Manual to determine whether or not to add ballast.

5.Always travel on roadways in such a way that faster moving vehicles may pass you safely.

6.Slow down when traveling over rough or hilly terrain.

7.Never

8.Be aware of negative hitch weight on the pull type Seed Bed Roller when in transporting. Negative hitch weight can cause loss of vehicle control. Add weight to the rear of the vehicle if needed.

9.Do not transport on a public roads with roller down. Damage to unit and/or road may occur.

12 Model SBR48, SBR60 & SBR72 Seed Bed Roller | 2/23/09 |