Air System | Air System Checklist |

| A. Air inlet faces the direction of prevailing winds. |

| B. Air outlet does not face noise sensitive areas without noise attenuating devices. |

| C. All heat loads have been taken into consideration in sizing air flow. |

| D. Gravity louvers face inward for air intake and outward for discharge. |

| E. Where electrically operated ventilation devices are used, power must be present under all |

| operating situations. Be certain these devices are on the emergency circuit. |

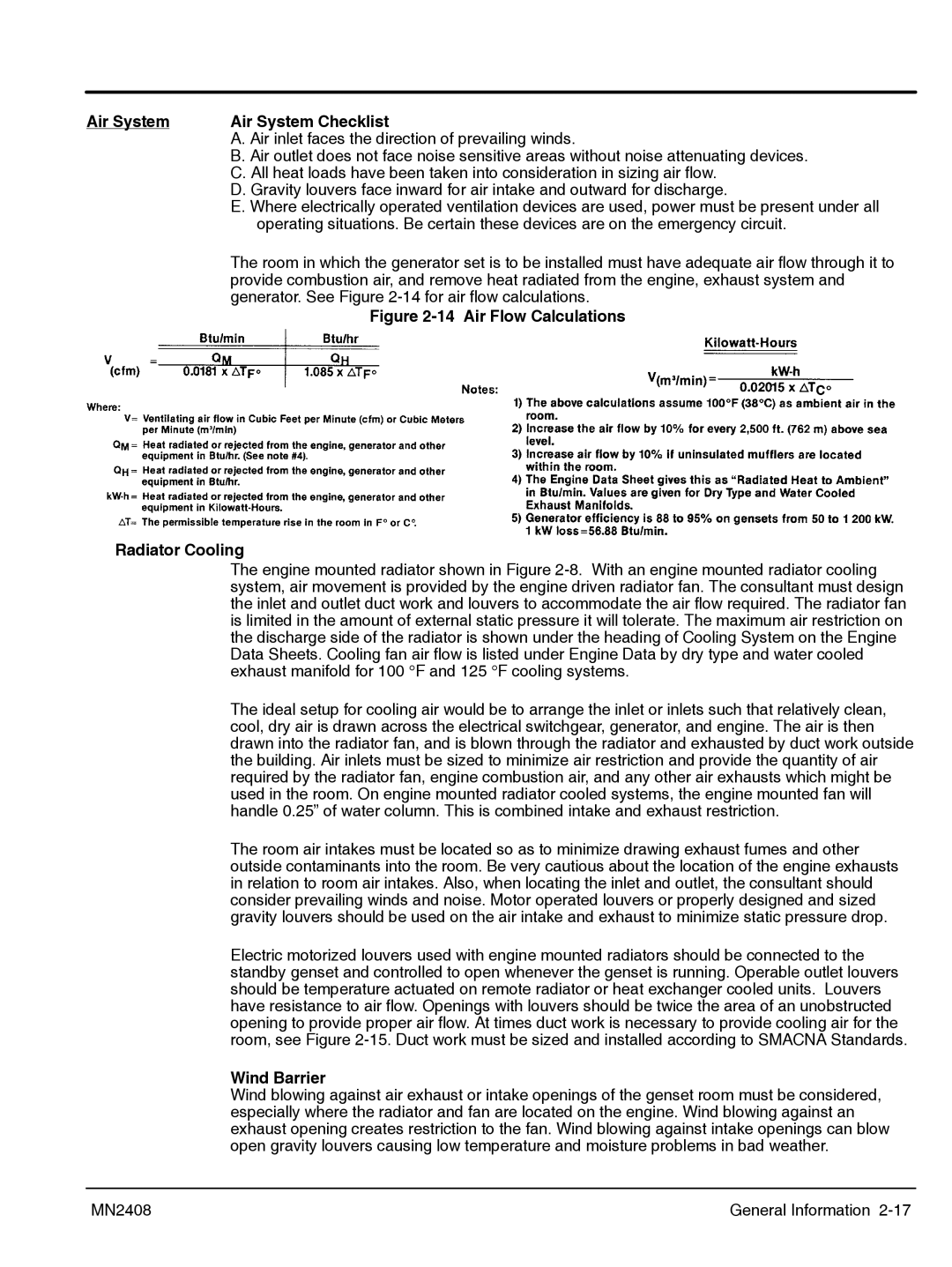

| The room in which the generator set is to be installed must have adequate air flow through it to |

| provide combustion air, and remove heat radiated from the engine, exhaust system and |

| generator. See Figure |

| Figure |

Radiator Cooling

The engine mounted radiator shown in Figure

The ideal setup for cooling air would be to arrange the inlet or inlets such that relatively clean, cool, dry air is drawn across the electrical switchgear, generator, and engine. The air is then drawn into the radiator fan, and is blown through the radiator and exhausted by duct work outside the building. Air inlets must be sized to minimize air restriction and provide the quantity of air required by the radiator fan, engine combustion air, and any other air exhausts which might be used in the room. On engine mounted radiator cooled systems, the engine mounted fan will handle 0.25” of water column. This is combined intake and exhaust restriction.

The room air intakes must be located so as to minimize drawing exhaust fumes and other outside contaminants into the room. Be very cautious about the location of the engine exhausts in relation to room air intakes. Also, when locating the inlet and outlet, the consultant should consider prevailing winds and noise. Motor operated louvers or properly designed and sized gravity louvers should be used on the air intake and exhaust to minimize static pressure drop.

Electric motorized louvers used with engine mounted radiators should be connected to the standby genset and controlled to open whenever the genset is running. Operable outlet louvers should be temperature actuated on remote radiator or heat exchanger cooled units. Louvers have resistance to air flow. Openings with louvers should be twice the area of an unobstructed opening to provide proper air flow. At times duct work is necessary to provide cooling air for the room, see Figure

Wind Barrier

Wind blowing against air exhaust or intake openings of the genset room must be considered, especially where the radiator and fan are located on the engine. Wind blowing against an exhaust opening creates restriction to the fan. Wind blowing against intake openings can blow open gravity louvers causing low temperature and moisture problems in bad weather.

MN2408 | General Information |