Battery Charger

An engine mounted alternator to charge the batteries during operation is an available option. Standby gensets require a solid state battery charger that is connected to utility power so the battery is charged continuously while the genset is not running. The battery charger should be connected to the emergency circuit. The batteries on prime power gensets are charged by the engine mounted alternator, if equipped.

Harmonic wave forms from solid state battery charges and belt driven alternators can cause the electronic governor on the engine to act erratically. To avoid this, the output of the battery charger or the belt driven alternator must be connected directly to the battery or to the battery terminals on the starter. Make control connections to the genset control using a conduit with a flexible section at the genset to avoid damage due to genset vibrations.

Battery Cables

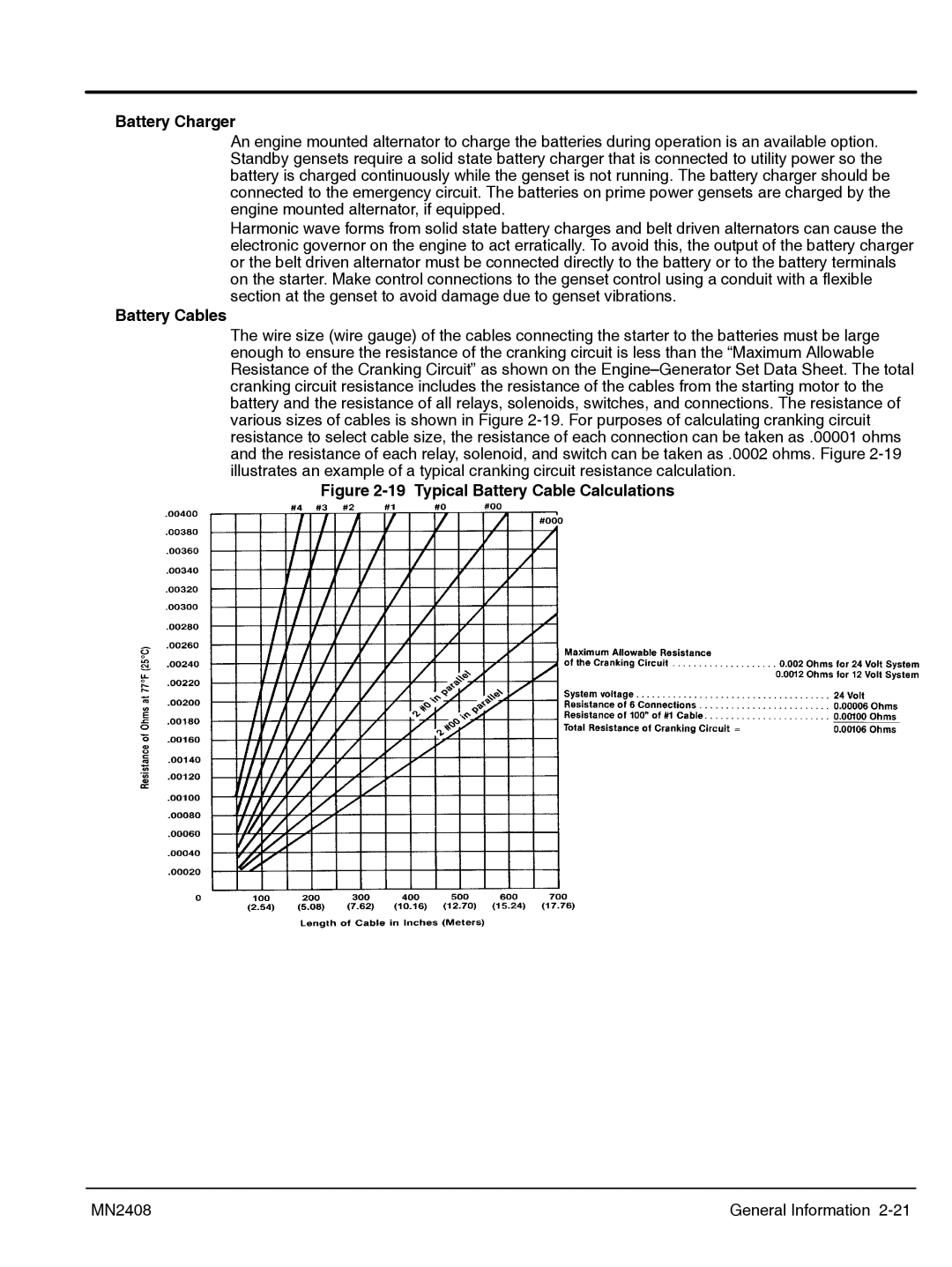

The wire size (wire gauge) of the cables connecting the starter to the batteries must be large enough to ensure the resistance of the cranking circuit is less than the “Maximum Allowable Resistance of the Cranking Circuit” as shown on the

Figure 2-19 Typical Battery Cable Calculations

MN2408 | General Information |