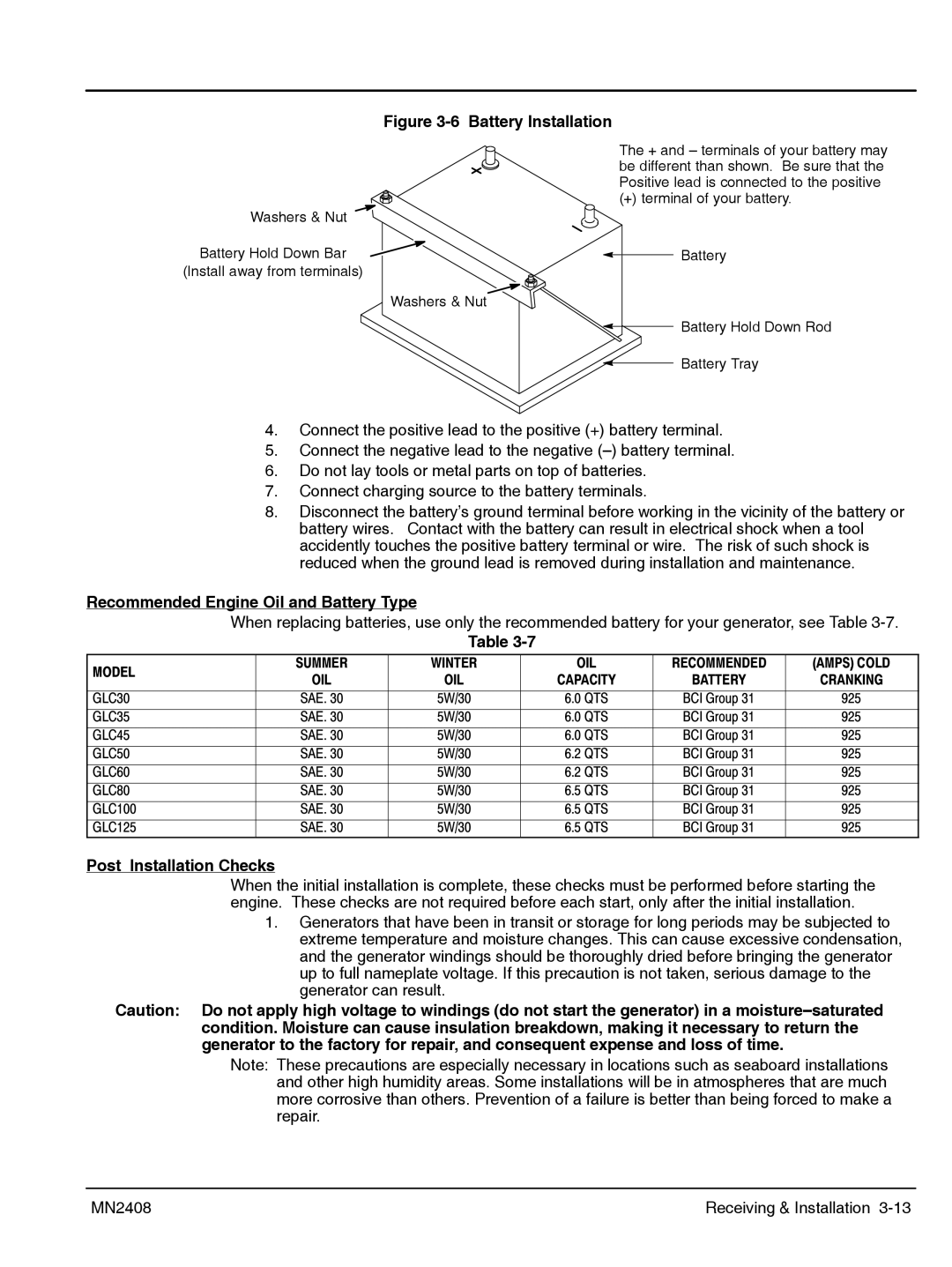

Figure 3-6 Battery Installation

Washers & Nut

Battery Hold Down Bar ![]() (Install away from terminals)

(Install away from terminals)

Washers & Nut

The + and – terminals of your battery may be different than shown. Be sure that the Positive lead is connected to the positive

(+)terminal of your battery.

![]() Battery

Battery

![]() Battery Hold Down Rod

Battery Hold Down Rod

![]() Battery Tray

Battery Tray

4.Connect the positive lead to the positive (+) battery terminal.

5.Connect the negative lead to the negative

6.Do not lay tools or metal parts on top of batteries.

7.Connect charging source to the battery terminals.

8.Disconnect the battery’s ground terminal before working in the vicinity of the battery or battery wires. Contact with the battery can result in electrical shock when a tool accidently touches the positive battery terminal or wire. The risk of such shock is reduced when the ground lead is removed during installation and maintenance.

Recommended Engine Oil and Battery Type

When replacing batteries, use only the recommended battery for your generator, see Table

Table

MODEL | SUMMER | WINTER | OIL | RECOMMENDED | (AMPS) COLD | |

OIL | OIL | CAPACITY | BATTERY | CRANKING | ||

| ||||||

|

|

|

|

|

| |

GLC30 | SAE. 30 | 5W/30 | 6.0 QTS | BCI Group 31 | 925 | |

GLC35 | SAE. 30 | 5W/30 | 6.0 QTS | BCI Group 31 | 925 | |

GLC45 | SAE. 30 | 5W/30 | 6.0 QTS | BCI Group 31 | 925 | |

GLC50 | SAE. 30 | 5W/30 | 6.2 QTS | BCI Group 31 | 925 | |

GLC60 | SAE. 30 | 5W/30 | 6.2 QTS | BCI Group 31 | 925 | |

GLC80 | SAE. 30 | 5W/30 | 6.5 QTS | BCI Group 31 | 925 | |

GLC100 | SAE. 30 | 5W/30 | 6.5 QTS | BCI Group 31 | 925 | |

GLC125 | SAE. 30 | 5W/30 | 6.5 QTS | BCI Group 31 | 925 |

Post Installation Checks

When the initial installation is complete, these checks must be performed before starting the engine. These checks are not required before each start, only after the initial installation.

1.Generators that have been in transit or storage for long periods may be subjected to extreme temperature and moisture changes. This can cause excessive condensation, and the generator windings should be thoroughly dried before bringing the generator up to full nameplate voltage. If this precaution is not taken, serious damage to the generator can result.

Caution: Do not apply high voltage to windings (do not start the generator) in a

Note: These precautions are especially necessary in locations such as seaboard installations and other high humidity areas. Some installations will be in atmospheres that are much more corrosive than others. Prevention of a failure is better than being forced to make a repair.

MN2408 | Receiving & Installation |