Remote Radiator Cooling

Remote Radiator Airflow generally assumed there will be no external restrictions to airflow. If this is not true, restriction must be considered in sizing and selection of a cooling fan and drive motor. Typical examples of restrictions include landscaping, nearby buildings, air turbulence created by buildings or other structures, and sight or noise “screens”. See Figure

Remote Radiator Fan Motor. Remote radiator cooling systems require the use of an electrically driven fan. This fan must be connected to the emergency power source. Size of the motor is determined by the fan size and fan speed.

1.To specify a radiator to cool the coolant you will need to determine the amount of heat rejected to the coolant. This is listed on the Engine Data Sheet as Heat Rejected to Coolant in BTU/min. for engines using dry or water cooled type exhaust manifolds, as applicable.

2.Determine the minimum water flow required at the engine, and the maximum top tank temperature. Using this information, determine the heat rejection capacity required of the radiator. Radiator systems should be sized with approximately 15% greater capacity than the engine’s maximum full load heat rejection to allow for overload and cooling system deterioration. Whether water flow is produced by an engine mounted or auxiliary pump, total piping system friction loss must be calculated. To do this, genset location, remote radiator location and friction loss within the radiator, and piping system must be estimated.

3.Pressure drop through the radiator must be obtained from radiator manufacturer.

4.If total piping system pressure exceeds the allowable Maximum Coolant Friction Head External to the engine as listed on the Engine Data Sheet, the coolant piping size should be increased and/or a radiator with less restriction must be used.

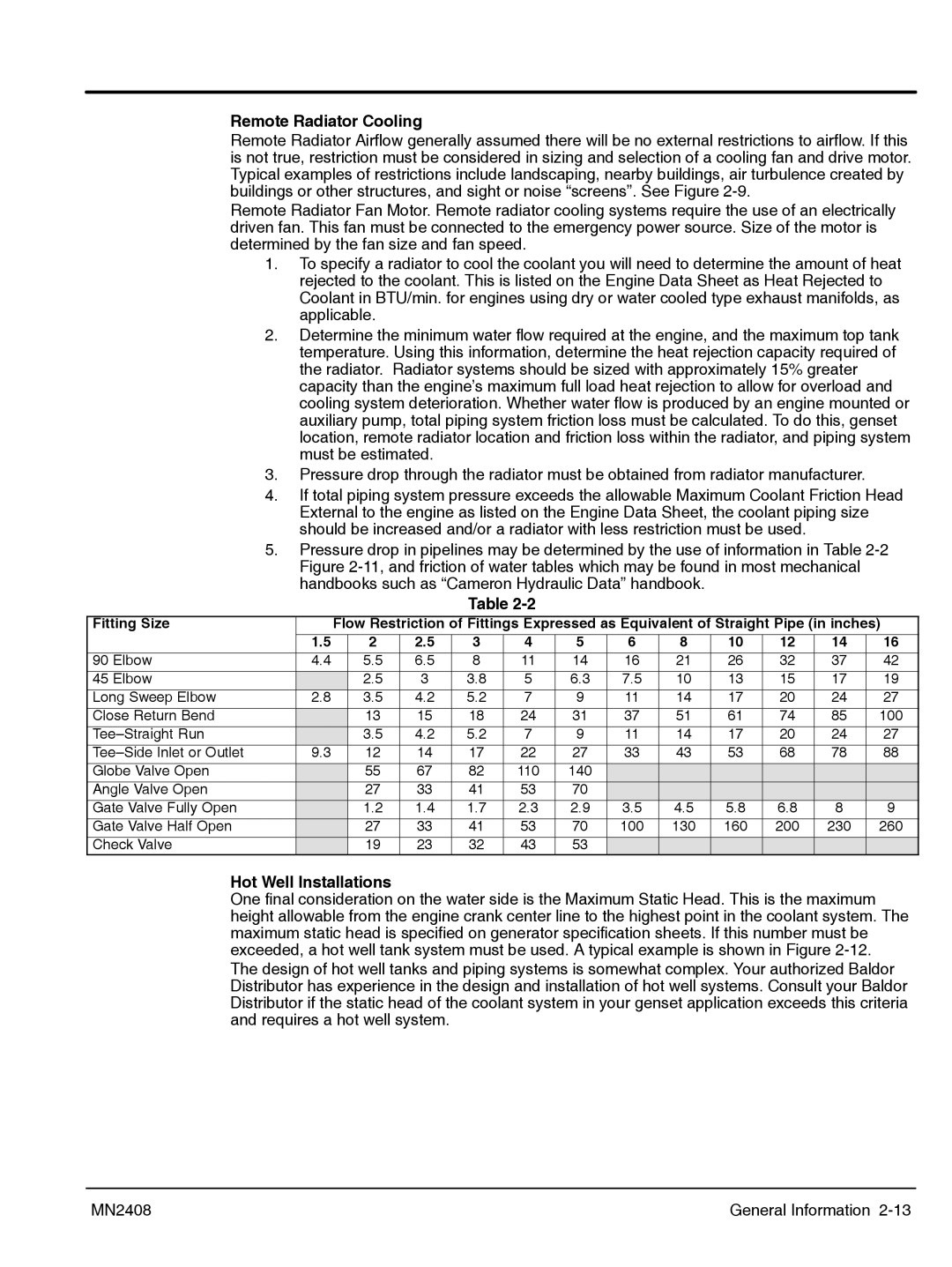

5.Pressure drop in pipelines may be determined by the use of information in Table

Table

Fitting Size |

| Flow Restriction of Fittings Expressed as Equivalent of Straight Pipe (in inches) | ||||||||||

| 1.5 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 |

90 Elbow | 4.4 | 5.5 | 6.5 | 8 | 11 | 14 | 16 | 21 | 26 | 32 | 37 | 42 |

45 Elbow |

| 2.5 | 3 | 3.8 | 5 | 6.3 | 7.5 | 10 | 13 | 15 | 17 | 19 |

Long Sweep Elbow | 2.8 | 3.5 | 4.2 | 5.2 | 7 | 9 | 11 | 14 | 17 | 20 | 24 | 27 |

Close Return Bend |

| 13 | 15 | 18 | 24 | 31 | 37 | 51 | 61 | 74 | 85 | 100 |

| 3.5 | 4.2 | 5.2 | 7 | 9 | 11 | 14 | 17 | 20 | 24 | 27 | |

9.3 | 12 | 14 | 17 | 22 | 27 | 33 | 43 | 53 | 68 | 78 | 88 | |

Globe Valve Open |

| 55 | 67 | 82 | 110 | 140 |

|

|

|

|

|

|

Angle Valve Open |

| 27 | 33 | 41 | 53 | 70 |

|

|

|

|

|

|

Gate Valve Fully Open |

| 1.2 | 1.4 | 1.7 | 2.3 | 2.9 | 3.5 | 4.5 | 5.8 | 6.8 | 8 | 9 |

Gate Valve Half Open |

| 27 | 33 | 41 | 53 | 70 | 100 | 130 | 160 | 200 | 230 | 260 |

Check Valve |

| 19 | 23 | 32 | 43 | 53 |

|

|

|

|

|

|

Hot Well Installations

One final consideration on the water side is the Maximum Static Head. This is the maximum height allowable from the engine crank center line to the highest point in the coolant system. The maximum static head is specified on generator specification sheets. If this number must be exceeded, a hot well tank system must be used. A typical example is shown in Figure

The design of hot well tanks and piping systems is somewhat complex. Your authorized Baldor Distributor has experience in the design and installation of hot well systems. Consult your Baldor Distributor if the static head of the coolant system in your genset application exceeds this criteria and requires a hot well system.

MN2408 | General Information |