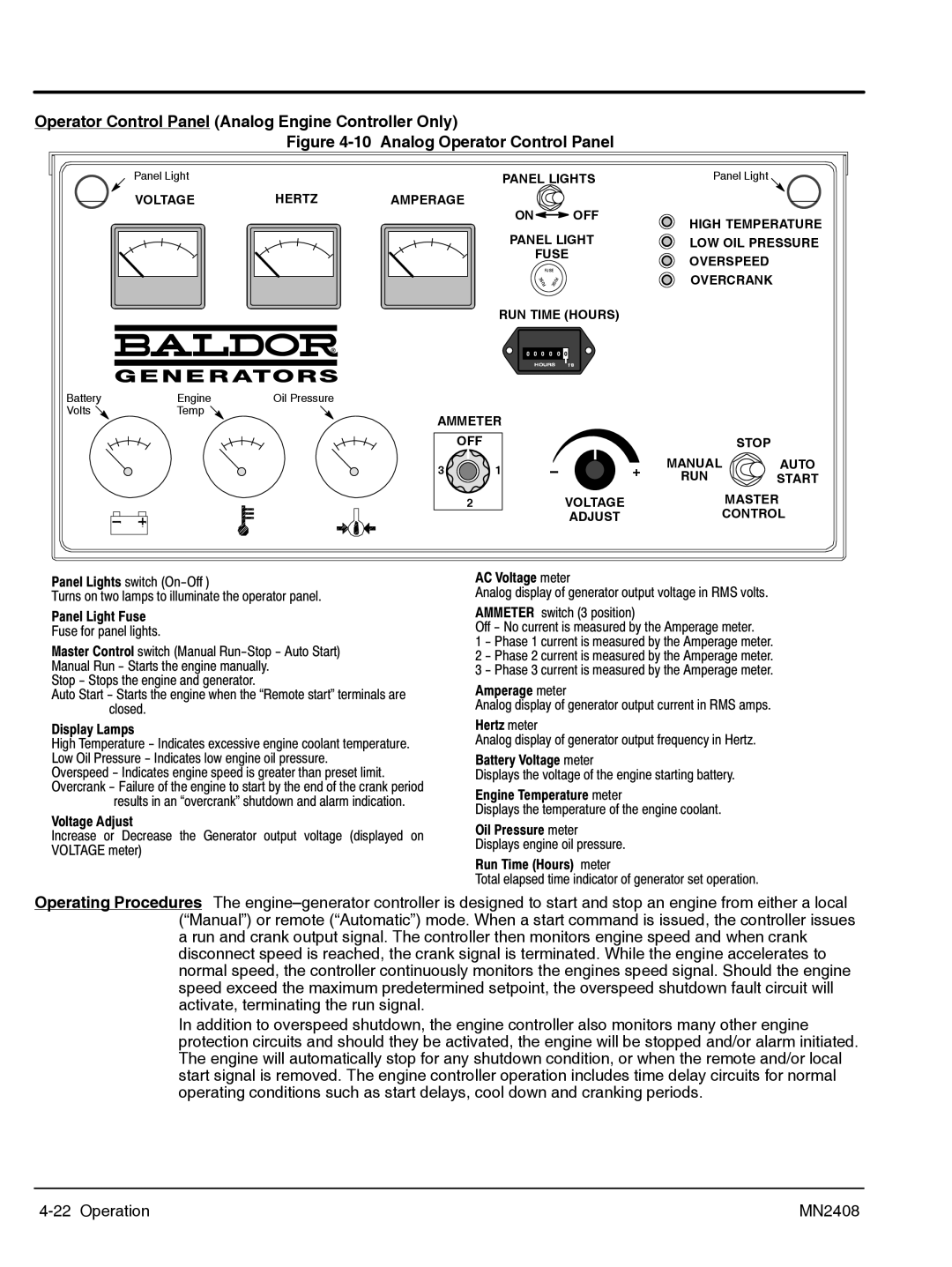

Operator Control Panel (Analog Engine Controller Only)

Figure 4-10 Analog Operator Control Panel

Panel Light |

| PANEL LIGHTS | Panel Light | |

VOLTAGE | HERTZ | AMPERAGE |

|

|

|

| ON | OFF | HIGH TEMPERATURE |

|

|

|

| |

|

| PANEL LIGHT | LOW OIL PRESSURE | |

|

|

| FUSE | OVERSPEED |

|

|

|

| |

|

|

|

| OVERCRANK |

|

| RUN TIME (HOURS) |

| |

Battery | Engine | Oil Pressure |

Volts | Temp | AMMETER |

|

|

| OFF |

|

|

| STOP | |

3 | 1 | – | + | MANUAL | AUTO | |

RUN | START | |||||

|

|

|

| |||

| 2 |

| VOLTAGE |

| MASTER | |

|

|

| ADJUST |

| CONTROL |

Panel Lights switch

Turns on two lamps to illuminate the operator panel.

Panel Light Fuse

Fuse for panel lights.

Master Control switch (Manual

Stop - Stops the engine and generator.

Auto Start - Starts the engine when the •Remote start" terminals are closed.

Display Lamps

High Temperature - Indicates excessive engine coolant temperature. Low Oil Pressure - Indicates low engine oil pressure.

Overspeed - Indicates engine speed is greater than preset limit. Overcrank - Failure of the engine to start by the end of the crank period

results in an •overcrank" shutdown and alarm indication.

Voltage Adjust

Increase or Decrease the Generator output voltage (displayed on VOLTAGE meter)

AC Voltage meter

Analog display of generator output voltage in RMS volts.

AMMETER switch (3 position)

Off - No current is measured by the Amperage meter.

1 - Phase 1 current is measured by the Amperage meter. 2 - Phase 2 current is measured by the Amperage meter. 3 - Phase 3 current is measured by the Amperage meter.

Amperage meter

Analog display of generator output current in RMS amps.

Hertz meter

Analog display of generator output frequency in Hertz.

Battery Voltage meter

Displays the voltage of the engine starting battery.

Engine Temperature meter

Displays the temperature of the engine coolant.

Oil Pressure meter Displays engine oil pressure.

Run Time (Hours) meter

Total elapsed time indicator of generator set operation.

Operating Procedures The

In addition to overspeed shutdown, the engine controller also monitors many other engine protection circuits and should they be activated, the engine will be stopped and/or alarm initiated. The engine will automatically stop for any shutdown condition, or when the remote and/or local start signal is removed. The engine controller operation includes time delay circuits for normal operating conditions such as start delays, cool down and cranking periods.

MN2408 |