Table of Contents

Section 3: Adjustments

Land Pride

IMPORTANT: Linch pins should always be inserted into the gauge wheel spindle pin holes from the front so that the locking clasp is flipped shut over the spindle towards the back. Attaching the pin in this manner will prevent vegetation from catching on the clasp and flipping it open while traveling forward.

5.After making height adjustments, always replace linch pins by inserting them into the gauge wheel spindle pin holes from the front to keep from loosing the pins and gauge wheels.

6.Lower mower decks to the field position making sure all fold cylinders are fully extended.

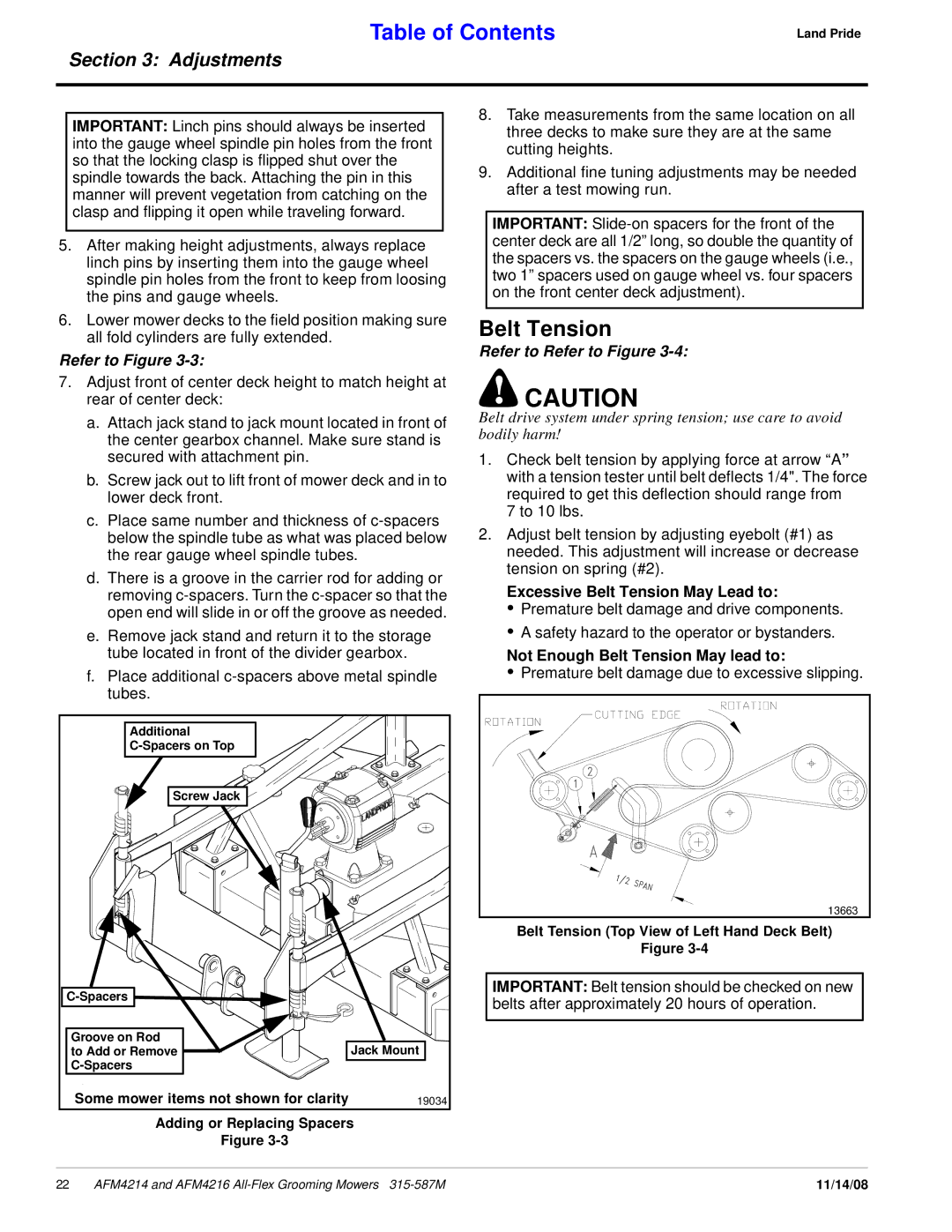

Refer to Figure 3-3:

7.Adjust front of center deck height to match height at rear of center deck:

a.Attach jack stand to jack mount located in front of the center gearbox channel. Make sure stand is secured with attachment pin.

b.Screw jack out to lift front of mower deck and in to lower deck front.

c.Place same number and thickness of

d.There is a groove in the carrier rod for adding or removing

e.Remove jack stand and return it to the storage tube located in front of the divider gearbox.

f.Place additional

Additional |

|

| |

Screw Jack |

|

| |

Groove on Rod | Jack Mount |

to Add or Remove | |

| |

Some mower items not shown for clarity | 19034 |

Adding or Replacing Spacers

Figure

8.Take measurements from the same location on all three decks to make sure they are at the same cutting heights.

9.Additional fine tuning adjustments may be needed after a test mowing run.

IMPORTANT:

Belt Tension

Refer to Refer to Figure 3-4:

!CAUTION

Belt drive system under spring tension; use care to avoid bodily harm!

1.Check belt tension by applying force at arrow “A” with a tension tester until belt deflects 1/4". The force required to get this deflection should range from

7 to 10 lbs.

2.Adjust belt tension by adjusting eyebolt (#1) as needed. This adjustment will increase or decrease tension on spring (#2).

Excessive Belt Tension May Lead to:

•Premature belt damage and drive components.

•A safety hazard to the operator or bystanders.

Not Enough Belt Tension May lead to:

• Premature belt damage due to excessive slipping. |

13663 |

Belt Tension (Top View of Left Hand Deck Belt)

Figure

IMPORTANT: Belt tension should be checked on new belts after approximately 20 hours of operation.

22 | AFM4214 and AFM4216 | 11/14/08 |