Table of Contents

Section 2 Operating Instructions

Land Pride

Section 2 Operating Instructions

Operating Check List

In addition to design and configuration of equipment; haz- ard control and accident prevention are dependent upon the awareness, concern, prudence and proper training in- volved in its operation, transport, maintenance and stor- age of equipment. Before beginning to operate your Cutter, the following inspection should be performed.

Check | Reference |

Read and follow the “Safety Rules” care- | Section 1 |

fully. | page 1 |

|

|

Read all of the "Tractor Hook Up" and prep- | Section 1 |

aration instructions. | page 10 |

|

|

“Operating Instructions” in this Manual | Section 2 |

| page 12 |

|

|

Lubricate the cutter as needed. Refer to | Section 5 |

"Lubrication" | page 19 |

|

|

Check the cutter initially and periodically for | Section 6 |

loose bolts & pins, "Torque Values Chart". | page 24 |

|

|

Make sure all guards and shields are in | Section 1 |

place. | page 3 |

|

|

Gearbox Gear Lube | Section 5 |

| page 20 |

|

|

!WARNING!

The following operating procedures should be carried out by the tractor operator. Other persons should be cleared of the area even during cutter setup. cutter operation should be stopped when in the vicinity of other persons.

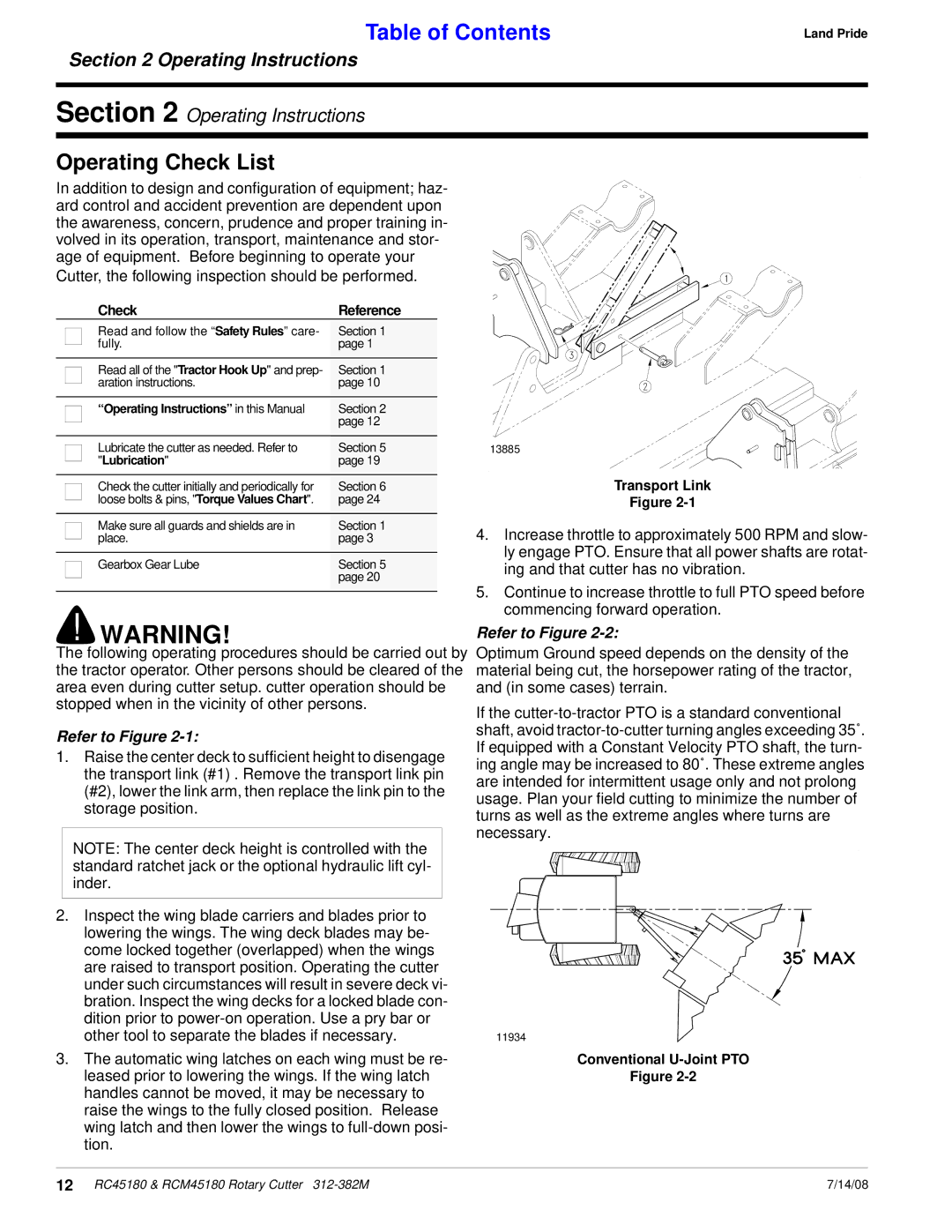

Refer to Figure 2-1:

1.Raise the center deck to sufficient height to disengage the transport link (#1) . Remove the transport link pin (#2), lower the link arm, then replace the link pin to the storage position.

NOTE: The center deck height is controlled with the standard ratchet jack or the optional hydraulic lift cyl- inder.

2.Inspect the wing blade carriers and blades prior to lowering the wings. The wing deck blades may be- come locked together (overlapped) when the wings are raised to transport position. Operating the cutter under such circumstances will result in severe deck vi- bration. Inspect the wing decks for a locked blade con- dition prior to

3.The automatic wing latches on each wing must be re- leased prior to lowering the wings. If the wing latch handles cannot be moved, it may be necessary to raise the wings to the fully closed position. Release wing latch and then lower the wings to

13885

Transport Link

Figure

4.Increase throttle to approximately 500 RPM and slow- ly engage PTO. Ensure that all power shafts are rotat- ing and that cutter has no vibration.

5.Continue to increase throttle to full PTO speed before commencing forward operation.

Refer to Figure 2-2:

Optimum Ground speed depends on the density of the material being cut, the horsepower rating of the tractor, and (in some cases) terrain.

If the

11934

Conventional

Figure

12 RC45180 & RCM45180 Rotary Cutter | 7/14/08 |