If you’re installing a gas line, connect it before the fireplace is framed and enclosed in the finished wall. The gas knockout is determined by the indentation located at the bottom and slightly off center in the side refractories. THE

KNOCKOUT IS ALWAYS REMOVED FROM IN- SIDE THE FIREPLACE. DO NOT REMOVE THE KNOCKOUT UNLESS YOU ARE INSTALLING A GAS LINE. If removal is attempted from the outer wrapper, side refractory damage may occur. With a medium-sized hammer, lightly tap the surface of the indentation. The refrac- tory material is very thin in this area and is easily removed. Once a small hole has been made, continue tapping until you have reached suffi- cient diameter for the gas line to fit through. The entire knockout does not have to be removed. Remove insulation in the gas line channel.

IMPORTANT: REPACK INSULATION MATERIAL IN SQUARE HOLE AROUND GAS LINE, INTE- RIOR AND EXTERIOR OF FIREPLACE, TO SEAL.

Glass Doors

If glass doors are to be installed on these fireplaces, refer to specific installation instruc- tions packed with the glass doors. Use only the doors that are listed for use with these fire- places. Use of other non-listed glass door on these fireplaces may constitute a potential fire hazard and is not recommended.

CAUTION: CERTAIN GLASS DOORS OVERLAP THE BLACK METAL FACING OF THE FIRE- PLACE. IF THE FIREPLACE HAS BEEN FACED WITH NONCOMBUSTIBLE MATERIALS, THERE MIGHT NOT BE SUFFICIENT CLEARANCE TO INSTALL THE GLASS DOORS OF YOUR CHOICE. ENSURE ADEQUATE CLEARANCE IS MAINTAINED AT ALL TIMES SO AS NOT TO INTERFERE WITH THE INSTALLATION AND OPERATION OF GLASS DOORS.

COLD CLIMATE INSULATION

If you live in a cold climate, it is especially important to seal all cracks around the fireplace opening with noncombustible material and wherever cold air could enter the room. Sur- rounding materials must be caulked where it meets the black metal facing of the fireplace to avoid cold air intrusion. Use noncombustible caulking material only on fireplace facing to seal. Also, the outside air inlet duct should be wrapped with noncombustible insulation to minimize the formation of condensation. Do not place insulation materials on top of fire- place or against chimney sections.

Note: A 2" air space must be preserved for all combustible materials extending for any con- tinuous length adjacent to the chimney.

It is especially important to insulate between the studs of an outside chase cavity and under the floor if the floor is above ground level. Do not place insulation directly against the fire- place or chimney system.

FIREPLACE FINISHES

Mantels and Trim

It is sometimes best to frame your fireplace after it is positioned and the chimney is in- stalled. Frame enclosure for chimney and fire- place with 2 x 4’s (or heavier) lumber.

Note: The header may rest on the two (2) metal top spacers on top of the unit but the header must not be notched to fit around the spacers.

These fireplaces may sit directly on a combus- tible surface. A 2" air space is required be- tween combustible framing and the chimney. A 1" air space is required between combustible framing and fireplace outer wrapper.

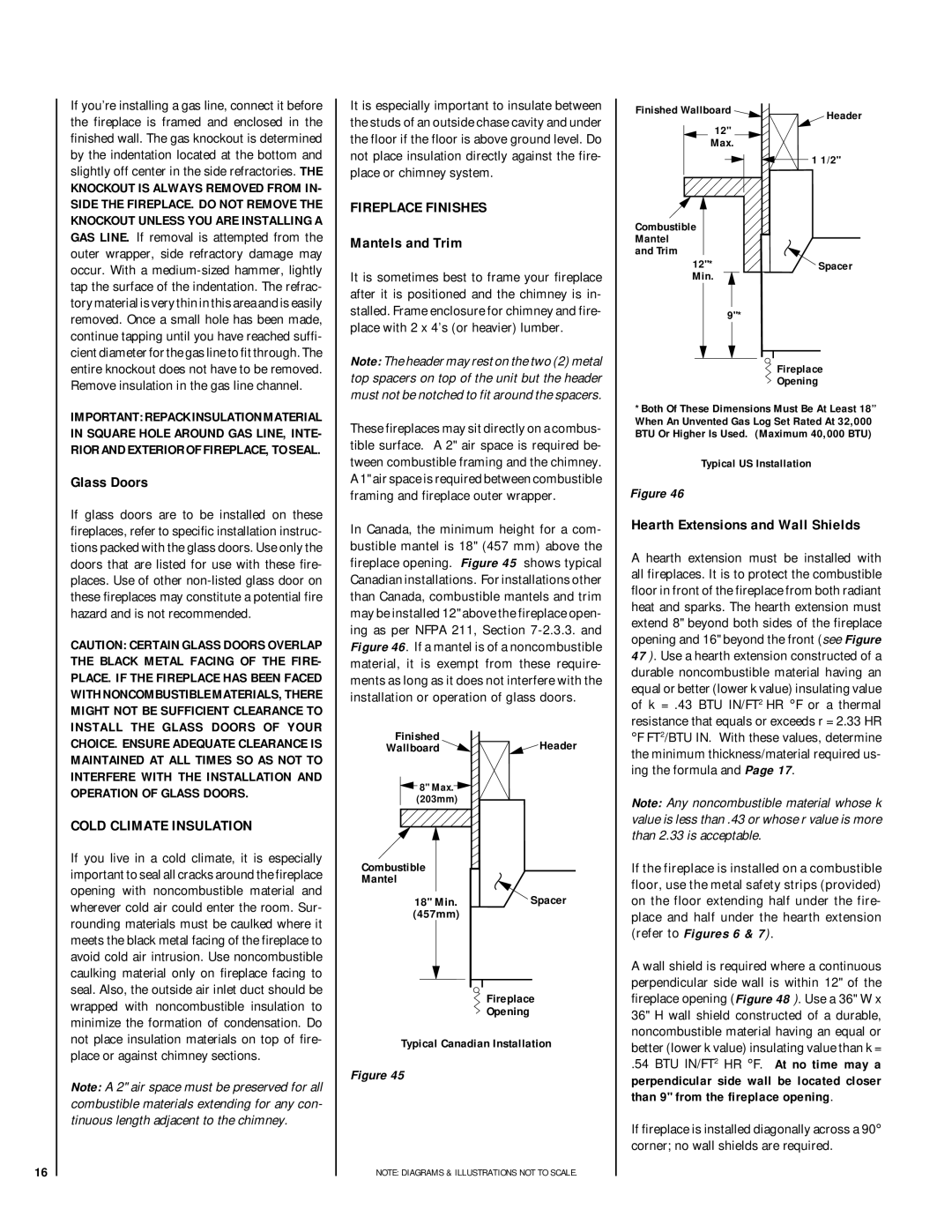

In Canada, the minimum height for a com- bustible mantel is 18" (457 mm) above the fireplace opening. Figure 45 shows typical Canadian installations. For installations other than Canada, combustible mantels and trim may be installed 12" above the fireplace open- ing as per NFPA 211, Section 7-2.3.3. and Figure 46. If a mantel is of a noncombustible material, it is exempt from these require- ments as long as it does not interfere with the installation or operation of glass doors.

Finished

Wallboard

Header

Header

8" Max.

8" Max.  (203mm)

(203mm)

Combustible

Mantel

Fireplace

Opening

Typical Canadian Installation

Figure 45

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Finished Wallboard | Header |

|

12" | |

Max. | |

| 1 1/2" |

Combustible | |

Mantel | |

and Trim | |

12"* | Spacer |

Min. | |

9"* | |

| Fireplace |

| Opening |

*Both Of These Dimensions Must Be At Least 18” When An Unvented Gas Log Set Rated At 32,000 BTU Or Higher Is Used. (Maximum 40,000 BTU)

Typical US Installation

Figure 46

Hearth Extensions and Wall Shields

A hearth extension must be installed with all fireplaces. It is to protect the combustible floor in front of the fireplace from both radiant heat and sparks. The hearth extension must extend 8" beyond both sides of the fireplace opening and 16" beyond the front (see Figure 47 ). Use a hearth extension constructed of a durable noncombustible material having an equal or better (lower k value) insulating value of k = .43 BTU IN/FT2 HR ° F or a thermal resistance that equals or exceeds r = 2.33 HR

°F FT2/BTU IN. With these values, determine the minimum thickness/material required us- ing the formula and Page 17.

Note: Any noncombustible material whose k value is less than .43 or whose r value is more than 2.33 is acceptable.

If the fireplace is installed on a combustible floor, use the metal safety strips (provided) on the floor extending half under the fire- place and half under the hearth extension (refer to Figures 6 & 7).

A wall shield is required where a continuous perpendicular side wall is within 12" of the fireplace opening (Figure 48 ). Use a 36" W x 36" H wall shield constructed of a durable, noncombustible material having an equal or better (lower k value) insulating value than k =

.54 BTU IN/FT2 HR ° F. At no time may a perpendicular side wall be located closer than 9" from the fireplace opening.

If fireplace is installed diagonally across a 90° corner; no wall shields are required.