Ð10Ð

|

|

|

|

|

|

|

|

|

|

|

|

| (WHEN USED) |

|

|

|

|

|

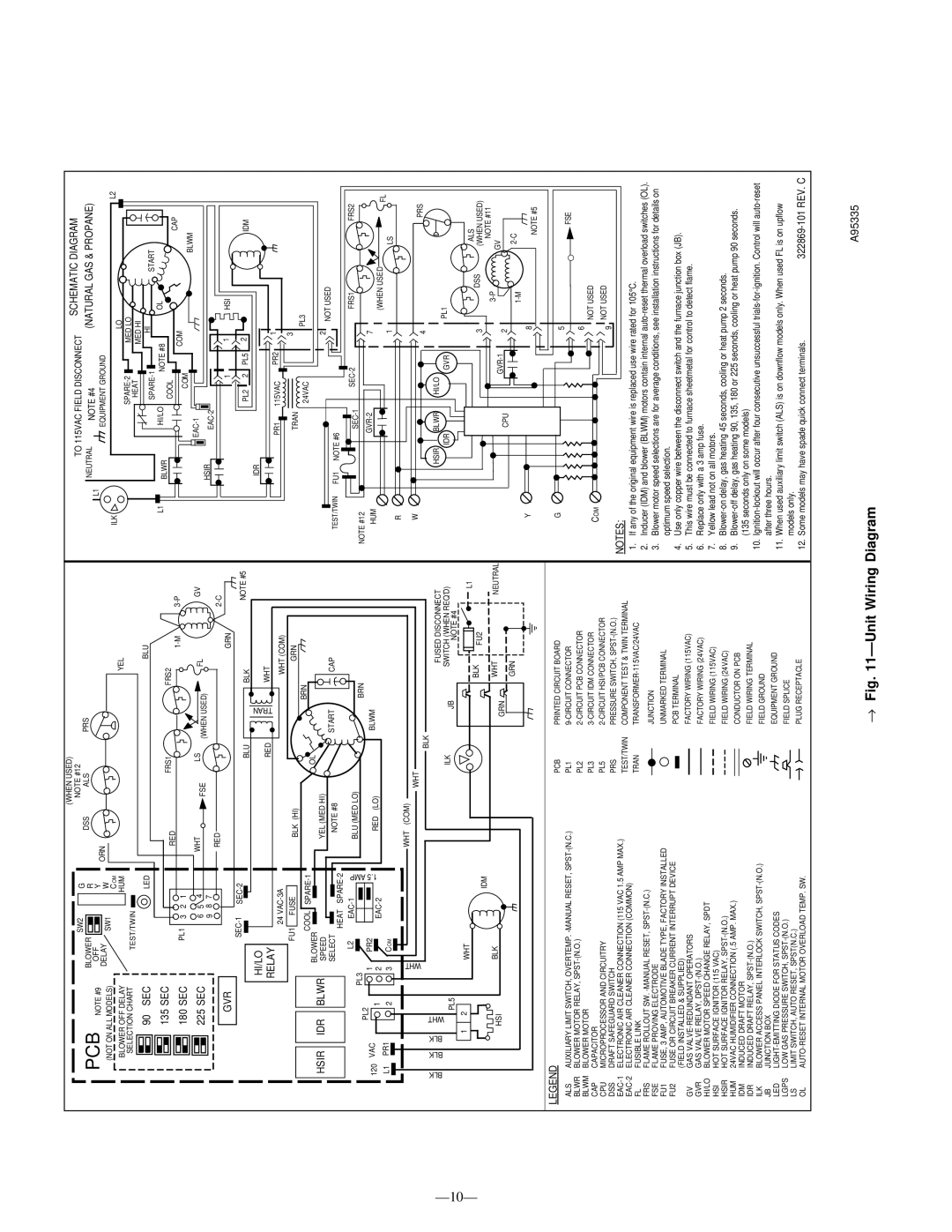

| TO 115VAC FIELD DISCONNECT | SCHEMATIC DIAGRAM |

| ||||||||

|

|

|

|

|

|

| SW2 |

|

| G |

| NOTE #12 |

|

|

|

|

|

|

| |||||||||||

|

|

|

|

|

|

|

|

|

| PRS |

|

|

|

|

|

|

|

| ||||||||||||

PCB |

|

| BLOWER |

|

| DSS | ALS |

|

|

|

|

| NEUTRAL |

|

|

|

|

|

| (NATURAL GAS & PROPANE) |

| |||||||||

|

|

|

|

|

| R |

|

|

|

|

| NOTE #4 |

|

|

|

|

| |||||||||||||

NOTE #9 |

| OFF |

|

|

|

| Y | ORN |

|

|

|

|

|

|

| L1 |

| EQUIPMENT GROUND |

|

|

|

|

| |||||||

| (NOT ON ALL MODELS) |

| DELAY | SW1 |

|

| W |

|

|

|

|

|

|

|

|

|

|

|

|

| L2 | |||||||||

|

|

|

|

|

|

|

|

|

|

|

| ILK |

|

|

|

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

| C OM |

|

|

|

| YEL |

|

|

|

|

|

|

|

|

|

| LO |

| ||

| BLOWER OFF DELAY |

|

|

|

|

| HUM |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||

| SELECTION CHART |

| TEST/TWIN |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| MED LO |

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| HEAT |

| MED HI |

|

| ||||||

|

|

| 90 | SEC |

|

|

|

|

|

| LED |

|

|

|

| BLU |

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| HI | START |

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| L1 |

|

| HI/LO |

|

| OL |

| ||||

|

|

| 135 SEC |

|

|

|

|

|

|

|

| FRS1 | FRS2 |

|

| BLWR | COOL |

| NOTE #8 |

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

| RED |

|

|

|

|

|

|

|

|

| CAP |

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||

|

|

| 180 SEC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| COM |

|

| |||||||

|

|

|

| PL1 | 3 | 2 | 1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| COM |

|

|

| |||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| BLWM |

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

| WHT |

| LS |

|

|

| GV |

|

|

|

|

|

|

|

|

| |||

|

|

| 225 SEC |

|

|

| 6 | 5 | 4 |

| FSE | (WHEN USED) | FL |

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

| HSIR |

|

|

|

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

| 9 | 8 | 7 |

| RED |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

| GVR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1 |

| 1 |

| HSI |

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| GRN |

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

| BLU |

| BLK |

| NOTE #5 |

|

|

|

| PL2 | 2 | PL5 | 2 |

|

| IDM |

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| TRAN |

|

|

|

|

|

|

|

| ||||||||

|

|

|

|

| HI/LO |

|

|

|

|

|

|

| RED | WHT |

|

|

| IDR |

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

| RELAY |

| 24 |

|

|

|

| WHT (COM) |

|

|

| PR1 | 115VAC |

| PR2 |

| 1 |

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 3 |

|

|

| ||||||

|

|

|

|

|

| FU1 | FUSE |

| BLK (HI) |

|

| GRN |

|

|

|

| TRAN |

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

| BRN |

|

|

|

|

|

|

|

|

| PL3 |

|

| ||||||||||

|

|

|

|

|

|

| COOL |

|

| OL |

|

|

|

|

|

|

| 24VAC |

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||

HSIR | IDR | BLWR | BLOWER |

|

|

|

| YEL (MED HI) |

|

|

|

|

|

|

|

|

|

|

|

| 2 |

|

|

| ||||||

SPEED |

|

|

|

|

|

| START | CAP |

|

|

|

|

|

|

|

|

|

| NOT USED |

|

| |||||||||

|

|

|

|

|

| SELECT |

|

|

|

|

| NOTE #8 |

|

|

| TEST/TWIN | FU1 | NOTE #6 |

|

|

|

|

|

|

| |||||

|

|

|

|

|

| HEAT |

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

| PL3 | L2 |

| AMP | BLU (MED LO) |

| BRN |

|

|

|

|

|

|

|

| FRS1 | FRS2 |

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| NOTE #12 |

|

|

|

|

|

|

|

|

|

| ||||||

|

|

| PL2 | PR2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

120 | VAC |

| 1 |

|

|

|

| 1.5 |

|

|

| BLWM |

|

|

| HUM |

|

|

|

|

|

| 7 |

|

|

| ||||

|

| 1 |

|

|

|

| RED | (LO) |

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||

|

| 2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

| (WHEN USED | FL | ||||||||||||

L1 | PR1 |

|

| COM |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||

|

| 2 | 3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1 |

| LS | ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| R |

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

| WHT (COM) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

| WHT |

|

|

|

|

|

|

|

|

|

| W |

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

| WHT | BLK |

|

|

|

|

|

|

|

|

|

| 4 |

| PRS |

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

| WHT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

BLK | BLK | BLK |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

| FUSED DISCONNECT |

|

| HSIR | BLWR | HI/LO |

|

|

| PL1 |

|

| |||||||

|

|

|

| PL5 |

|

|

|

|

|

|

|

|

| ILK | JB | SWITCH (WHEN REQ'D) |

|

| IDR |

|

|

| GVR |

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| NOTE #4 |

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

| 1 | 2 |

| WHT |

|

|

|

|

|

|

|

|

|

|

| L1 |

|

|

|

|

|

|

|

|

|

| ALS |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| BLK | FU2 |

|

|

|

|

|

|

|

| 3 | DSS |

| ||

|

|

|

|

|

|

|

|

|

|

| IDM |

|

|

|

|

|

|

|

|

|

|

|

|

| (WHEN USED) | |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| NOTE #11 |

| ||

|

|

|

|

|

| BLK |

|

|

|

|

|

|

|

|

| WHT |

| NEUTRAL |

|

|

|

|

|

|

|

|

|

| ||

|

|

| HSI |

|

|

|

|

|

|

|

|

|

| GRN |

|

|

|

|

|

|

| 2 | GV |

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| CPU |

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| GRN |

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Y |

|

|

|

|

|

|

| 8 | NOTE #5 |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

LEGEND

ALS | AUXILIARY LIMIT SWITCH, OVERTEMP. |

BLWR | BLOWER MOTOR RELAY, |

BLWM | BLOWER MOTOR |

CAP | CAPACITOR |

CPU | MICROPROCESSOR AND CIRCUITRY |

DSS | DRAFT SAFEGUARD SWITCH |

ELECTRONIC AIR CLEANER CONNECTION (115 VAC 1.5 AMP MAX.) | |

ELECTRONIC AIR CLEANER CONNECTION (COMMON) | |

FL | FUSIBLE LINK |

FRS | FLAME ROLLOUT SW. |

FSE | FLAME PROVING ELECTRODE |

FU1 | FUSE, 3 AMP, AUTOMOTIVE BLADE TYPE, FACTORY INSTALLED |

FU2 | FUSE OR CIRCUIT BREAKER CURRENT INTERRUPT DEVICE |

| (FIELD INSTALLED & SUPPLIED) |

GV | GAS |

GVR | GAS VALVE RELAY, |

HI/LO | BLOWER MOTOR SPEED CHANGE RELAY, SPDT |

HSI | HOT SURFACE IGNITOR (115 VAC) |

HSIR | HOT SURFACE IGNITOR RELAY, |

HUM | 24VAC HUMIDIFIER CONNECTION (.5 AMP. MAX.) |

IDM | INDUCED DRAFT MOTOR |

IDR | INDUCED DRAFT RELAY, |

ILK | BLOWER ACCESS PANEL INTERLOCK SWITCH, |

JB | JUNCTION BOX |

LED | |

LGPS | LOW GAS PRESSURE SWITCH, |

LS | LIMIT SWITCH, AUTO RESET, SPST(N.C.) |

OL |

|

| PCB | PRINTED CIRCUIT BOARD | ||||||

|

| PL1 | |||||||

|

| PL2 | |||||||

|

| PL3 | |||||||

|

| PL5 | |||||||

|

| PRS | PRESSURE SWITCH, | ||||||

|

| TEST/TWIN | COMPONENT TEST & TWIN TERMINAL | ||||||

|

| TRAN | |||||||

|

|

|

|

|

|

|

|

| JUNCTION |

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

| UNMARKED TERMINAL |

|

|

|

|

|

|

|

|

| PCB TERMINAL |

|

|

|

|

|

|

|

|

| FACTORY WIRING (115VAC) |

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

| FACTORY WIRING (24VAC) |

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

| FIELD WIRING (115VAC) |

|

|

|

|

|

|

|

|

| FIELD WIRING (24VAC) |

|

|

|

|

|

|

|

|

| CONDUCTOR ON PCB |

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

| FIELD WIRING TERMINAL |

|

|

|

|

|

|

|

|

| FIELD GROUND |

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

| EQUIPMENT GROUND |

|

|

|

|

|

|

|

|

| FIELD SPLICE |

|

|

|

|

|

|

|

|

| PLUG RECEPTACLE |

|

|

|

|

|

|

|

|

| |

G

COM

NOTES:

5

6

9

NOT USED NOT USED