A CLOSER LOOK

FEATURES

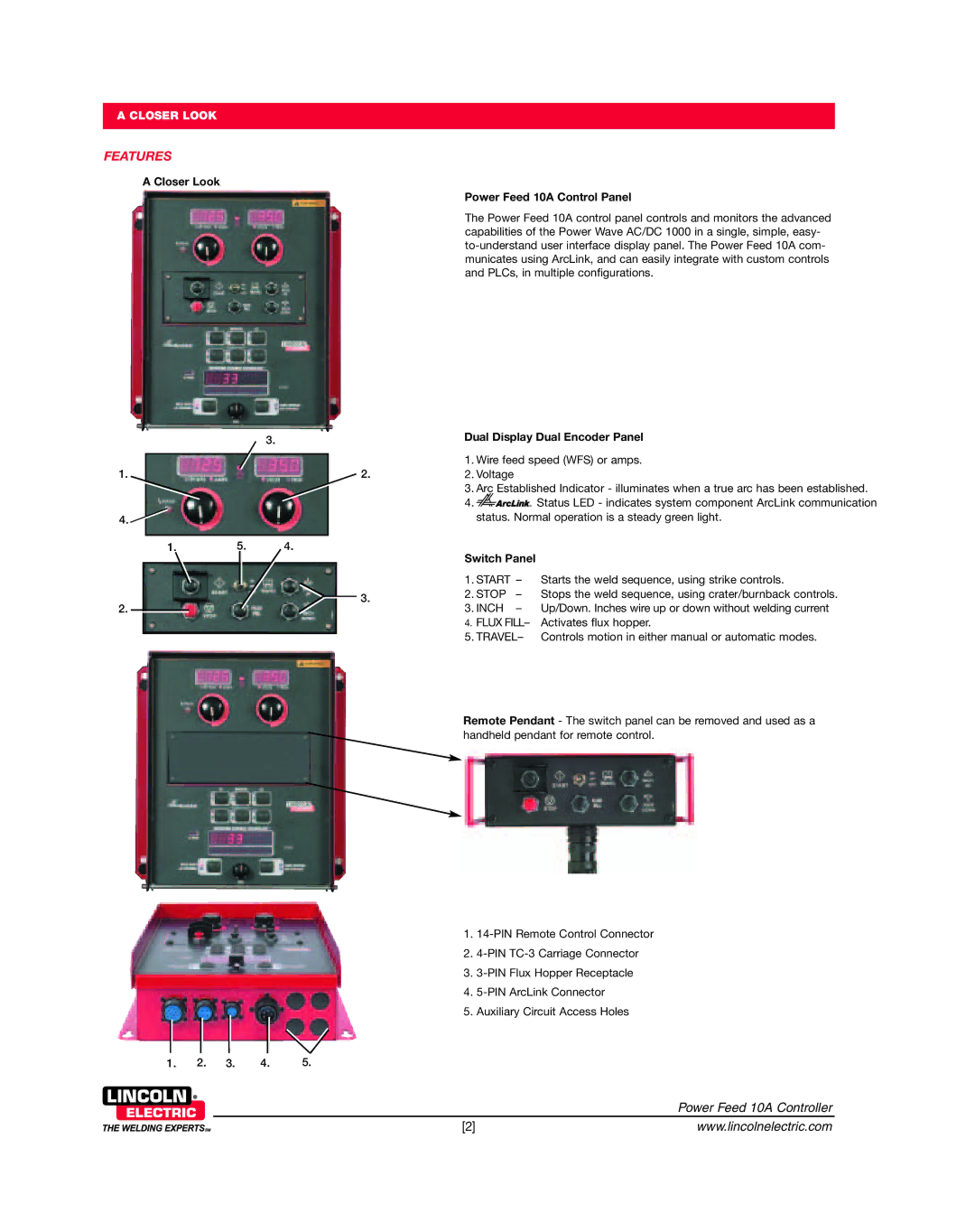

A Closer Look

3.

1.

4.

1.5. 4.

2.

Power Feed 10A Control Panel

The Power Feed 10A control panel controls and monitors the advanced capabilities of the Power Wave AC/DC 1000 in a single, simple, easy-

| Dual Display Dual Encoder Panel | |

| 1. Wire feed speed (WFS) or amps. | |

2. | 2. Voltage | |

| 3. Arc Established Indicator - illuminates when a true arc has been established. | |

| 4. | ® Status LED - indicates system component ArcLink communication |

|

| status. Normal operation is a steady green light. |

| Switch Panel |

| ||

| 1. START | – | Starts the weld sequence, using strike controls. | |

3. | 2. STOP | – | Stops the weld sequence, using crater/burnback controls. | |

3. INCH | – | Up/Down. Inches wire up or down without welding current | ||

| ||||

| 4. FLUX FILL– | Activates flux hopper. | ||

| 5. TRAVEL– | Controls motion in either manual or automatic modes. | ||

Remote Pendant - The switch panel can be removed and used as a handheld pendant for remote control.

1.

2.

3.

4.

5. Auxiliary Circuit Access Holes

1. | 2. | 3. | 4. | 5. |

| Power Feed 10A Controller |

[2] | www.lincolnelectric.com |