SEMIAUTOMATIC WIRE FEEDERS

| Power Feed™ 10M |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Single and Dual Bench Wire Feeders |

|

|

|

|

|

|

|

|

|

| When you need a versatile, |

|

|

|

| |||||

| material, you need the Power Feed 10M. Choose the Power Feed 10M for automotive |

|

|

|

| |||||

| manufacturing, shipbuilding, pressure vessels/heavy plate, oil, gas and pipeline |

|

|

|

| |||||

| construction, particularly when |

|

|

|

| |||||

| interface panel features the Infrared Port with a Palm® |

|

|

|

| |||||

| wireless communication between a handheld device and the welding system, for fast, |

|

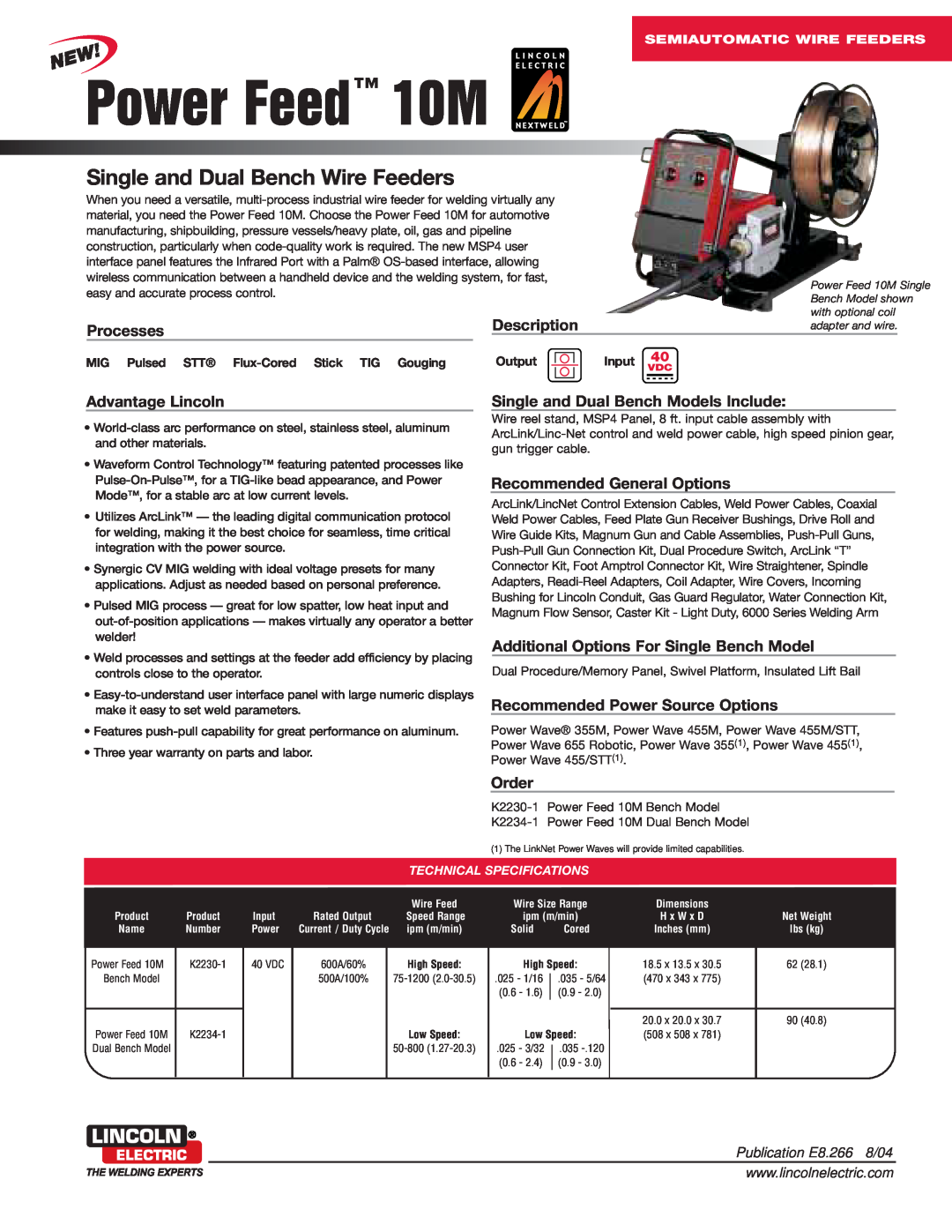

| Power Feed 10M Single | ||||||

| easy and accurate process control. |

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

| Bench Model shown | ||

|

|

|

|

|

|

|

|

| ||

|

| Description |

|

| with optional coil | |||||

| Processes |

|

| adapter and wire. | ||||||

|

|

|

|

|

|

| 40 |

|

| |

| MIG Pulsed STT® | Output |

|

|

|

| Input |

|

| |

|

|

|

|

|

| |||||

|

|

|

| |||||||

|

|

|

|

|

|

|

| VDC | ||

|

|

|

|

|

|

|

|

|

|

|

| Advantage Lincoln | Single and Dual Bench Models Include: |

| |||||||

•

•Waveform Control Technology™ featuring patented processes like

•Utilizes ArcLink™ — the leading digital communication protocol for welding, making it the best choice for seamless, time critical integration with the power source.

•Synergic CV MIG welding with ideal voltage presets for many applications. Adjust as needed based on personal preference.

•Pulsed MIG process — great for low spatter, low heat input and

•Weld processes and settings at the feeder add efficiency by placing controls close to the operator.

•

•Features

•Three year warranty on parts and labor.

Wire reel stand, MSP4 Panel, 8 ft. input cable assembly with

Recommended General Options

ArcLink/LincNet Control Extension Cables, Weld Power Cables, Coaxial Weld Power Cables, Feed Plate Gun Receiver Bushings, Drive Roll and Wire Guide Kits, Magnum Gun and Cable Assemblies,

Additional Options For Single Bench Model

Dual Procedure/Memory Panel, Swivel Platform, Insulated Lift Bail

Recommended Power Source Options

Power Wave® 355M, Power Wave 455M, Power Wave 455M/STT, Power Wave 655 Robotic, Power Wave 355(1), Power Wave 455(1), Power Wave 455/STT(1).

Order

Product |

| Product |

|

|

Name |

| Number |

|

|

|

| |||

|

|

|

|

|

Power Feed 10M |

| |||

Bench Model |

|

|

|

|

|

|

|

|

|

Power Feed 10M |

| |||

Dual Bench Model |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Power Feed 10M Bench Model |

| ||

|

|

|

|

|

| Power Feed 10M Dual Bench Model |

| ||

|

|

|

|

|

| (1) The LinkNet Power Waves will provide limited capabilities. |

| ||

|

|

|

| TECHNICAL SPECIFICATIONS |

|

| |||

|

|

|

| Wire Feed |

| Wire Size Range | Dimensions |

| |

Input |

| Rated Output | Speed Range |

| ipm (m/min) | H x W x D | Net Weight | ||

Power |

| Current / Duty Cycle | ipm (m/min) |

| Solid | Cored | Inches (mm) | lbs (kg) | |

40 VDC |

| 600A/60% |

| High Speed: |

| High Speed: | 18.5 x 13.5 x 30.5 |

| |

|

|

| 62 (28.1) | ||||||

|

| 500A/100% |

|

| .025 - 1/16 .035 - 5/64 | (470 x 343 x 775) |

| ||

|

|

|

|

|

| (0.6 - 1.6) | (0.9 - 2.0) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 20.0 x 20.0 x 30.7 | 90 (40.8) |

|

|

|

| Low Speed: |

| Low Speed: | (508 x 508 x 781) |

| |

|

|

|

|

| .025 - 3/32 .035 |

|

| ||

|

|

|

|

|

| (0.6 - 2.4) | (0.9 - 3.0) |

|

|

|

|

|

|

|

|

|

|

|

|

Publication E8.266 8/04

www.lincolnelectric.com