A CLOSER LOOK

WELDING CURRENT

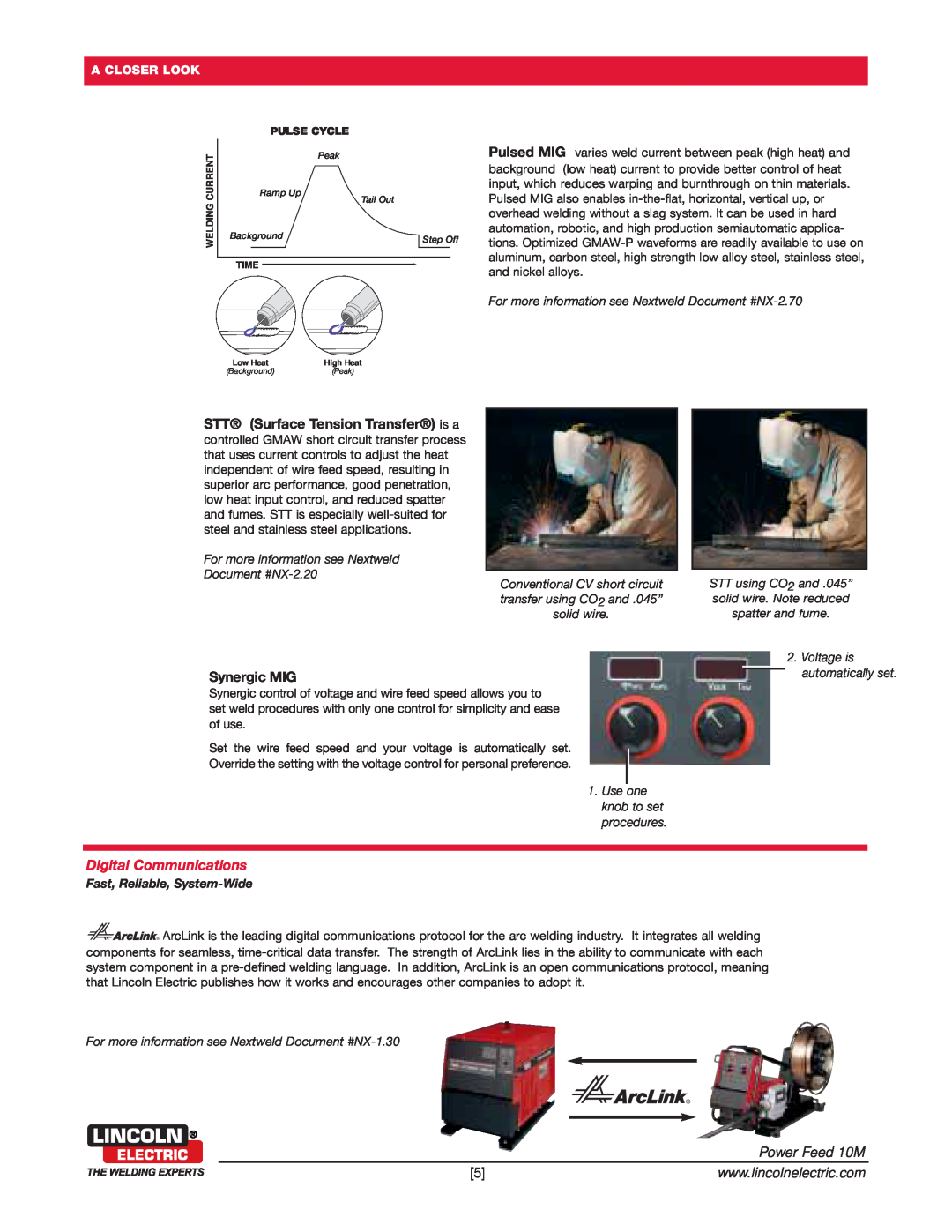

PULSE CYCLE

|

| Peak | Pulsed MIG varies weld current between peak (high heat) and | |||

|

|

|

|

| background (low heat) current to provide better control of heat | |

Ramp Up |

|

|

| input, which reduces warping and burnthrough on thin materials. | ||

Tail Out | Pulsed MIG also enables | |||||

|

| |||||

|

|

|

|

| overhead welding without a slag system. It can be used in hard | |

Background |

| Step Off | automation, robotic, and high production semiautomatic applica- | |||

| tions. Optimized | |||||

|

|

| ||||

|

|

|

|

| aluminum, carbon steel, high strength low alloy steel, stainless steel, | |

TIME |

|

|

|

| ||

|

|

|

| and nickel alloys. | ||

|

|

|

|

| ||

For more information see Nextweld Document #NX-2.70

Low Heat | High Heat |

(Background) | (Peak) |

STT® (Surface Tension Transfer®) is a controlled GMAW short circuit transfer process that uses current controls to adjust the heat independent of wire feed speed, resulting in superior arc performance, good penetration, low heat input control, and reduced spatter and fumes. STT is especially

For more information see Nextweld

Document

Conventional CV short circuit transfer using CO2 and .045” solid wire.

Synergic MIG

Synergic control of voltage and wire feed speed allows you to set weld procedures with only one control for simplicity and ease of use.

Set the wire feed speed and your voltage is automatically set. Override the setting with the voltage control for personal preference.

1. Use one knob to set procedures.

STT using CO2 and .045” solid wire. Note reduced spatter and fume.

2.Voltage is automatically set.

Digital Communications

Fast, Reliable, System-Wide

![]()

![]()

![]()

![]() ® ArcLink is the leading digital communications protocol for the arc welding industry. It integrates all welding components for seamless,

® ArcLink is the leading digital communications protocol for the arc welding industry. It integrates all welding components for seamless,

For more information see Nextweld Document #NX-1.30

®

Power Feed 10M

[5] | www.lincolnelectric.com |