|

| LEARNING TO WELD |

| ||

|

|

|

|

|

|

FIGURE B.12

Penetration

Unless a weld penetrates close to 100% of the metal thickness, a butt weld will be weaker than the material welded together. In the example shown in Figure B.13, the total weld is only half the thickness of the material thus the weld is only approximately half as strong as the metal.

FIGURE B.13

FIGURE B.14

In the example shown in Figure B.14, the joint has been welded so that 100% penetration could be achieved. The weld, if properly made, is as strong as or stronger than the original metal.

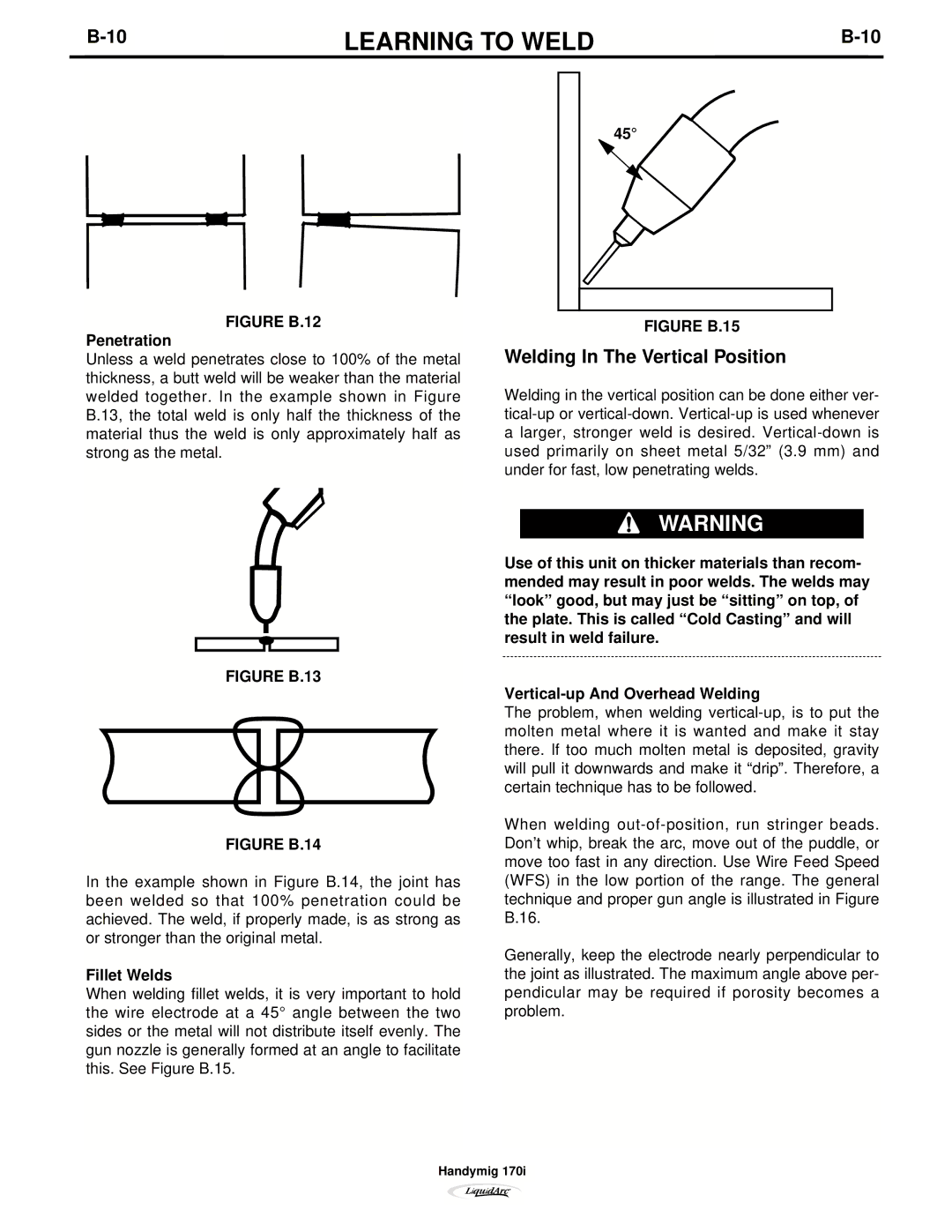

Fillet Welds

When welding fillet welds, it is very important to hold the wire electrode at a 45° angle between the two sides or the metal will not distribute itself evenly. The gun nozzle is generally formed at an angle to facilitate this. See Figure B.15.

45°

FIGURE B.15

Welding In The Vertical Position

Welding in the vertical position can be done either ver-

alarger, stronger weld is desired.

WARNING

Use of this unit on thicker materials than recom- mended may result in poor welds. The welds may “look” good, but may just be “sitting” on top, of the plate. This is called “Cold Casting” and will result in weld failure.

The problem, when welding

When welding

Generally, keep the electrode nearly perpendicular to the joint as illustrated. The maximum angle above per- pendicular may be required if porosity becomes a problem.

Handymig 170i