A CLOSER LOOK

PERFORMANCE

Arc Performance

•Pure DC generator welding arc is preferredby pipelinersand contractorsfor precise code consistency.

•DC exciterfor supplyingpure DC currentto the weldinggeneratoras desired by the most discriminatingoperators.

•All copper windings enhance arc stability.

•Custom Arc® 150 RPM high idle (OCV) adjustmentrange — enhanced fine tuning for performanceon pipe.

•200 amps DC @ 60% duty cycle, 104˚F (40˚C). Weld up to 7/32” (5.6mm) low hydrogenelectrode.

•Gouge with up to 5/32" (4.0 mm) carbons.

DC AuxiliaryPerformance

•1,750 total watts of DC auxiliary power from a single 120V outlet for grinders and lights. DC power is less likely to bog down a grinder comparedto AC power.(Not for use with AC voltage equipment.)

Use the High Idle (OCV) engine speed adjustmentdial to change the heat input to the arc:

•Set the arc in the machine’s“sweet spot”.

•Dial in a softer or more digging arc.

•Reduce root pass internal undercut,especiallyon X60 and X70 pipe.

•Stack iron faster with low heat and a clear puddle on fill passes.

•Avoid arc breaks. Avoid slag that crowds the arc.

•Control fusion on the cap pass with good puddle size and clarity.

FEATURES

•Quiet,

•Noise at 200A/40V rated output: 97.9 dB sound power (Lwa), 73.6 dBA at 23 ft. (7 m)

•Five overlappingcurrent ranges for stick pipe welding and other processeswhere slope control is desired.

•Gauges indicate oil pressure,engine temperatureand battery charg- ing amps.

•

•Oil drain system is standard. Includes ball valve and hose to direct oil beyond the base of the machine.

•Compact size for installationon truck beds.

•Local/Remoteswitch and remote receptacleare factory installed to allow easy connectionof the optional remote control.

Stick Welding

•Optional

Wire Welding

•Optional Wire Feed Module for

•Optional

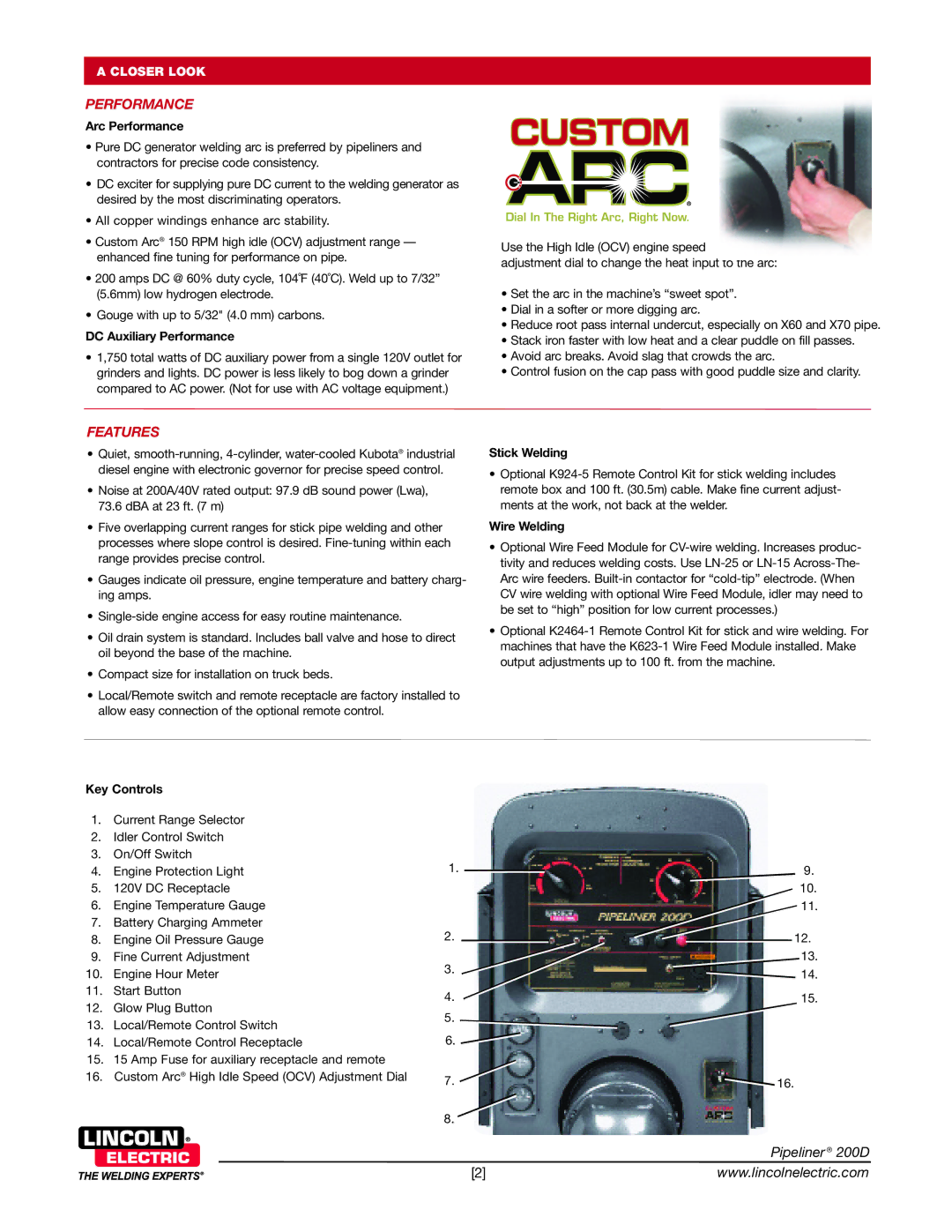

Key Controls

1.Current Range Selector

2.Idler Control Switch

3.On/Off Switch

4. | Engine Protection Light | 1. |

|

| 9. | |||||

| ||||||||||

5. | 120V DC Receptacle |

|

|

| 10. | |||||

6. | Engine Temperature Gauge |

|

|

| 11. | |||||

7. | Battery Charging Ammeter | 2. |

|

|

|

| ||||

8. | Engine Oil Pressure Gauge |

|

|

| 12. | |||||

|

|

| ||||||||

9. | Fine Current Adjustment | 3. |

|

| 13. | |||||

10. | Engine Hour Meter |

|

| 14. | ||||||

|

|

| ||||||||

11. | Start Button | 4. |

|

| 15. | |||||

12. | Glow Plug Button |

|

| |||||||

5. |

|

|

|

| ||||||

13. | Local/Remote Control Switch |

|

|

|

| |||||

|

|

|

|

| ||||||

14. | Local/Remote Control Receptacle | 6. |

|

|

|

| ||||

15. | 15 Amp Fuse for auxiliary receptacle and remote |

|

|

|

|

| ||||

16. Custom Arc® High Idle Speed (OCV) Adjustment Dial | 7. |

|

| 16. | ||||||

|

|

|

|

|

|

|

| |||

|

|

|

|

|

| 8. |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Pipeliner ® 200D |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

| [2] |

| www.lincolnelectric.com | ||

|

|

|

|

|

|

| ||||