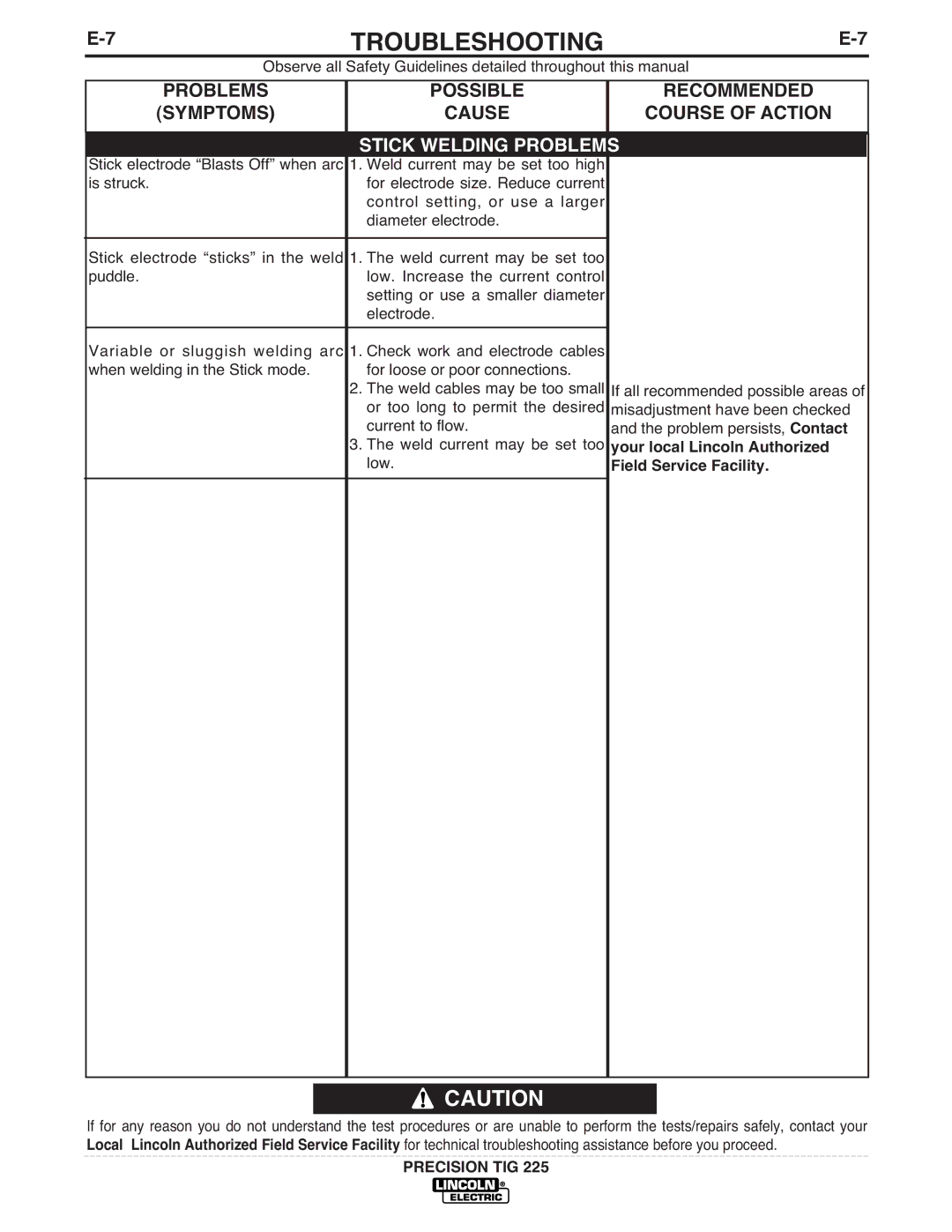

| TROUBLESHOOTING | ||

|

|

|

|

| Observe all Safety Guidelines detailed throughout this manual | ||

|

|

|

|

| PROBLEMS | POSSIBLE | RECOMMENDED |

| (SYMPTOMS) | CAUSE | COURSE OF ACTION |

STICK WELDING PROBLEMS

Stick electrode “Blasts Off” when arc | 1. | Weld current may be set too high |

is struck. |

| for electrode size. Reduce current |

|

| control setting, or use a larger |

|

| diameter electrode. |

|

|

|

Stick electrode “sticks” in the weld | 1. | The weld current may be set too |

puddle. |

| low. Increase the current control |

|

| setting or use a smaller diameter |

|

| electrode. |

|

|

|

Variable or sluggish welding arc | 1. | Check work and electrode cables |

when welding in the Stick mode. |

| for loose or poor connections. |

| 2. | The weld cables may be too small |

|

| or too long to permit the desired |

|

| current to flow. |

| 3. | The weld current may be set too |

|

| low. |

|

|

|

|

|

|

If all recommended possible areas of misadjustment have been checked and the problem persists, Contact your local Lincoln Authorized Field Service Facility.

![]()

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.