| INSTALLATION | ||

COAXIAL WELD CABLE |

| ||

Coaxial welding cables are specially designed welding |

| ||

cables for STT™ and pulse welding. Coaxial weld cables |

| ||

feature low inductance, allowing fast changes in the weld |

| ||

current. Regular cables have a higher inductance which Electrode |

| ||

may distort the | STT™ waveshape. Inductance becomes |

| |

more severe as the weld cables become longer.

Coaxial weld cables are recommended for STT™ weld- ing, especially when the total weld cable length (elec- trode cable + work cable) exceeds 50 feet (7.6m). See Table A.2.

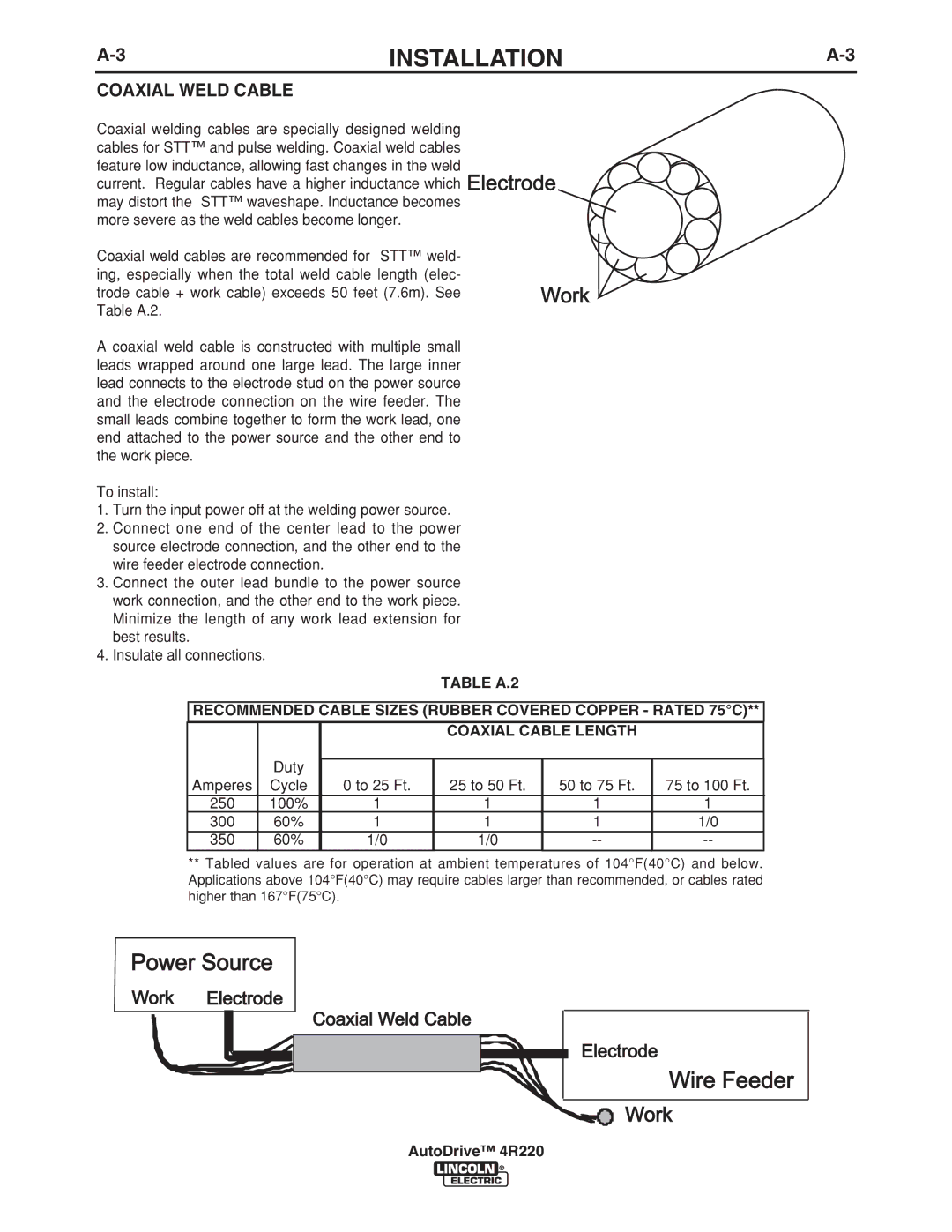

A coaxial weld cable is constructed with multiple small leads wrapped around one large lead. The large inner lead connects to the electrode stud on the power source and the electrode connection on the wire feeder. The small leads combine together to form the work lead, one end attached to the power source and the other end to the work piece.

To install:

1.Turn the input power off at the welding power source.

2.Connect one end of the center lead to the power source electrode connection, and the other end to the wire feeder electrode connection.

3.Connect the outer lead bundle to the power source work connection, and the other end to the work piece. Minimize the length of any work lead extension for best results.

4.Insulate all connections.

Work

TABLE A.2

RECOMMENDED CABLE SIZES (RUBBER COVERED COPPER - RATED 75°C)**

COAXIAL CABLE LENGTH

| Duty |

|

|

|

|

|

Amperes | Cycle | 0 to 25 Ft. | 25 to 50 Ft. | 50 to 75 Ft. | 75 to 100 Ft. | |

250 | 100% |

| 1 | 1 | 1 | 1 |

300 | 60% |

| 1 | 1 | 1 | 1/0 |

350 | 60% |

| 1/0 | 1/0 | ||

**Tabled values are for operation at ambient temperatures of 104°F(40°C) and below. Applications above 104°F(40°C) may require cables larger than recommended, or cables rated higher than 167°F(75°C).

Power Source

Work Electrode

Coaxial Weld Cable

Electrode

Wire Feeder

Work |

AutoDrive™ 4R220