PILOT ARC DISCUSSION

OPERATION

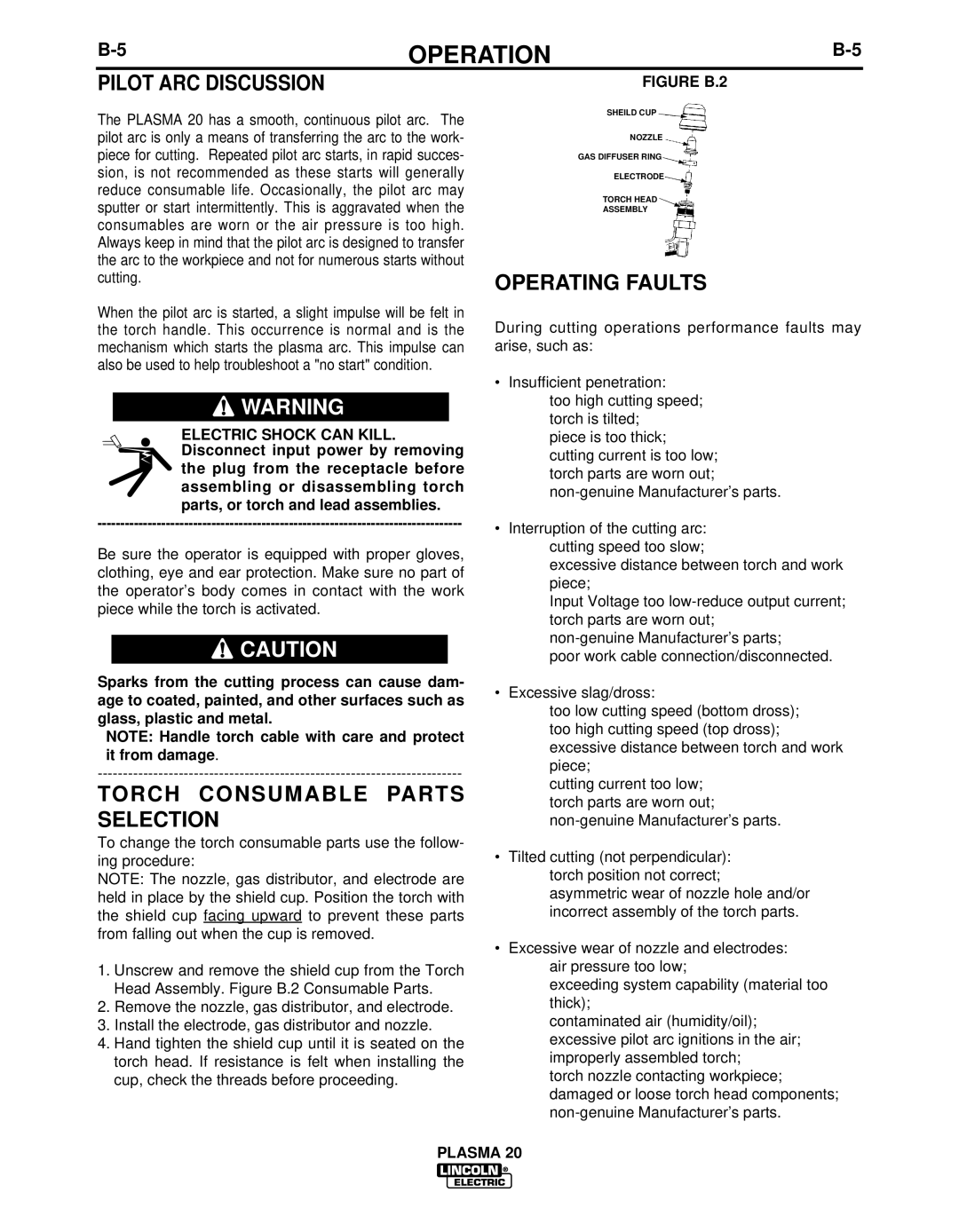

FIGURE B.2

The PLASMA 20 has a smooth, continuous pilot arc. The pilot arc is only a means of transferring the arc to the work- piece for cutting. Repeated pilot arc starts, in rapid succes- sion, is not recommended as these starts will generally reduce consumable life. Occasionally, the pilot arc may sputter or start intermittently. This is aggravated when the consumables are worn or the air pressure is too high. Always keep in mind that the pilot arc is designed to transfer the arc to the workpiece and not for numerous starts without cutting.

When the pilot arc is started, a slight impulse will be felt in the torch handle. This occurrence is normal and is the mechanism which starts the plasma arc. This impulse can also be used to help troubleshoot a "no start" condition.

![]() WARNING

WARNING

ELECTRIC SHOCK CAN KILL.

Disconnect input power by removing the plug from the receptacle before assembling or disassembling torch parts, or torch and lead assemblies.

Be sure the operator is equipped with proper gloves, clothing, eye and ear protection. Make sure no part of the operator’s body comes in contact with the work piece while the torch is activated.

![]() CAUTION

CAUTION

Sparks from the cutting process can cause dam- age to coated, painted, and other surfaces such as glass, plastic and metal.

NOTE: Handle torch cable with care and protect it from damage.

TORCH CONSUMABLE PARTS SELECTION

To change the torch consumable parts use the follow- ing procedure:

NOTE: The nozzle, gas distributor, and electrode are held in place by the shield cup. Position the torch with the shield cup facing upward to prevent these parts from falling out when the cup is removed.

1.Unscrew and remove the shield cup from the Torch Head Assembly. Figure B.2 Consumable Parts.

2.Remove the nozzle, gas distributor, and electrode.

3.Install the electrode, gas distributor and nozzle.

4.Hand tighten the shield cup until it is seated on the torch head. If resistance is felt when installing the cup, check the threads before proceeding.

SHEILD CUP ![]()

NOZZLE

GAS DIFFUSER RING

ELECTRODE![]()

TORCH HEAD ![]()

ASSEMBLY

OPERATING FAULTS

During cutting operations performance faults may arise, such as:

• Insufficient penetration:

too high cutting speed; torch is tilted;

piece is too thick; cutting current is too low; torch parts are worn out;

•Interruption of the cutting arc: cutting speed too slow;

excessive distance between torch and work piece;

Input Voltage too

poor work cable connection/disconnected.

•Excessive slag/dross:

too low cutting speed (bottom dross); too high cutting speed (top dross); excessive distance between torch and work piece;

cutting current too low; torch parts are worn out;

•Tilted cutting (not perpendicular): torch position not correct; asymmetric wear of nozzle hole and/or incorrect assembly of the torch parts.

•Excessive wear of nozzle and electrodes: air pressure too low;

exceeding system capability (material too thick);

contaminated air (humidity/oil); excessive pilot arc ignitions in the air; improperly assembled torch;

torch nozzle contacting workpiece; damaged or loose torch head components;

PLASMA 20