OPERATION | ||

|

|

|

Unlike other VRD’s Lincoln uses micro processor con- trol to monitor and establish the arc without the stick- ing and shorting of the electrode to the job as seen in many other VRD installations. Due to the requirement of the resistance in the circuit to be low, for a VRD to operate, a good

Any damaged connection anywhere in the output cir- cuit may limit the operation of the VRD. This includes a good connection of the work return clamp and the job. The work return clamp should be connected close as practical to where the welding will be performed.

Some electrodes form a cone at the end of the elec- trode after the welding arc has been broken, particu- larly iron powder and low hydrogen electrodes.

This cone will need to be broken off in order to have the metal core of the electrode to make contact.

STARTING TECHNIQUE

The starting technique that has successfully overcome the problem is the push, twist, and peel technique. This technique requires the operator to push the elec- trode into the joint and twist.

The Push and Twist breaks off the cone and allows the metal electrode to make contact.

The peel and lift of the electrode establishes a con- trolled start to the welding arc. Normal welding tech- nique for the application is then used.

bREAK-IN PERIOD

The engine used to supply power for your welder is a heavy duty, industrial engine. It is designed and built for rugged use. It is very normal for any engine to use small quantities of oil until the

IMPORTANT

IN ORDER TO ACCOMPLISH THIS

TYPICAL FUEL CONSUMPTION

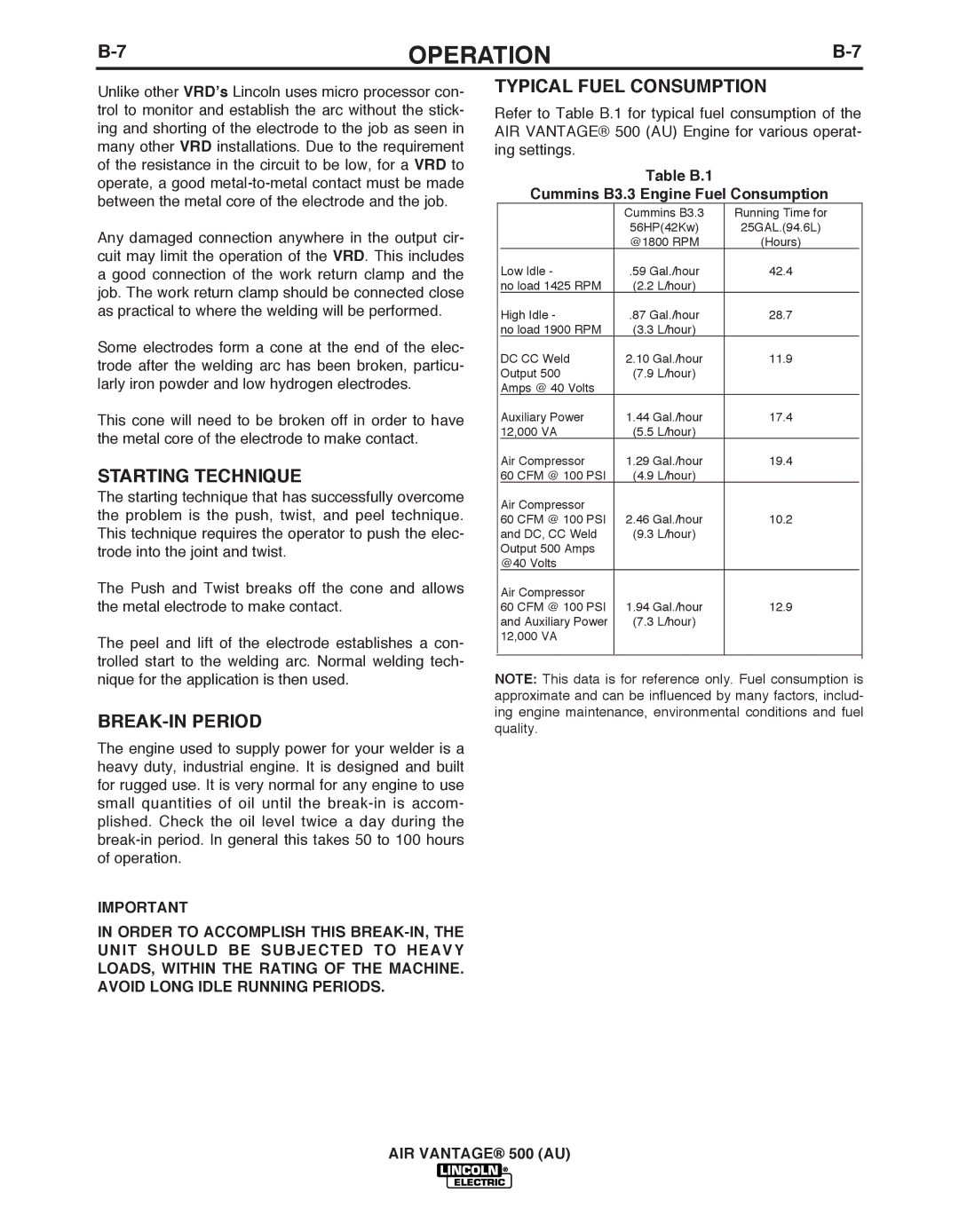

Refer to Table B.1 for typical fuel consumption of the AIR VANTAGE® 500 (AU) Engine for various operat- ing settings.

Table b.1

Cummins b3.3 Engine Fuel Consumption

|

| Cummins B3.3 | Running Time for |

|

|

| 56HP(42Kw) | 25GAL.(94.6L) |

|

|

| @1800 RPM | (Hours) |

|

| Low Idle - | .59 Gal./hour | 42.4 |

|

| no load 1425 RPM | (2.2 L/hour) |

|

|

| High Idle - | .87 Gal./hour | 28.7 |

|

| no load 1900 RPM | (3.3 L/hour) |

|

|

| DC CC Weld | 2.10 Gal./hour | 11.9 |

|

| Output 500 | (7.9 L/hour) |

|

|

| Amps @ 40 Volts |

|

|

|

| Auxiliary Power | 1.44 Gal./hour | 17.4 |

|

| 12,000 VA | (5.5 L/hour) |

|

|

| Air Compressor | 1.29 Gal./hour | 19.4 |

|

| 60 CFM @ 100 PSI | (4.9 L/hour) |

|

|

| Air Compressor |

|

|

|

| 60 CFM @ 100 PSI | 2.46 Gal./hour | 10.2 |

|

| and DC, CC Weld | (9.3 L/hour) |

|

|

| Output 500 Amps |

|

|

|

| @40 Volts |

|

|

|

| Air Compressor |

|

|

|

| 60 CFM @ 100 PSI | 1.94 Gal./hour | 12.9 |

|

| and Auxiliary Power | (7.3 L/hour) |

|

|

| 12,000 VA |

|

|

|

|

|

|

|

|

|

|

|

|

|

NOTE: This data is for reference only. Fuel consumption is approximate and can be influenced by many factors, includ- ing engine maintenance, environmental conditions and fuel quality.

AIR VANTAGE® 500 (AU)