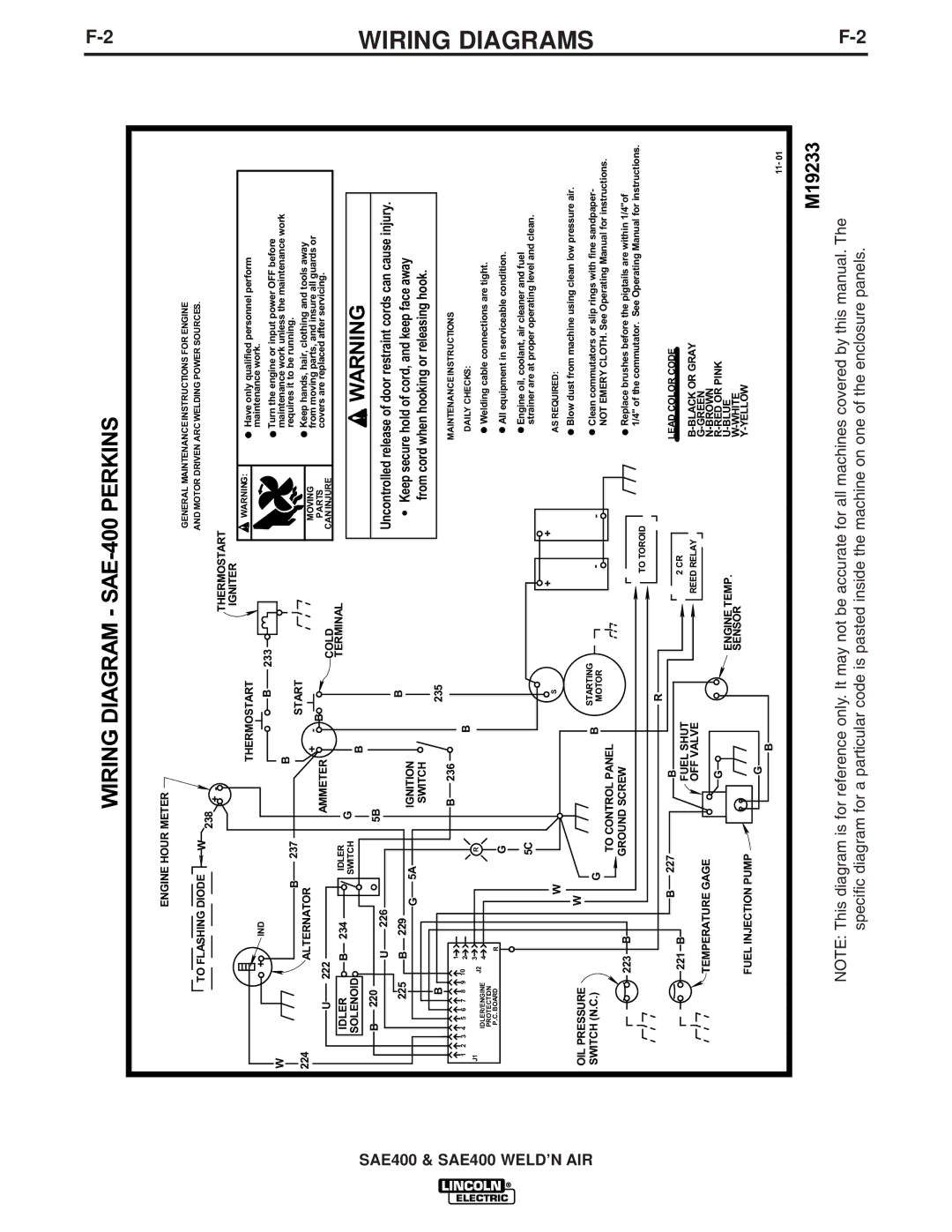

SAE400 & SAE400 WELD’N AIR

WIRING DIAGRAM - SAE-400 PERKINS

ENGINE HOUR METER

|

|

|

|

|

|

|

|

|

|

|

| GENERAL MAINTENANCEINSTRUCTIONS FOR ENGINE | |

| TO FLASHING DIODE | W |

|

|

|

|

|

| AND MOTOR DRIVEN ARC WELDING POWER SOURCES. | ||||

| 238 | + | - |

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

| THERMOSTART |

| |||

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

| IGNITER |

|

|

|

|

|

|

|

|

|

| THERMOSTART |

| WARNING: | Have only qualified personnel perform | ||

|

|

|

|

|

|

|

|

|

| ||||

|

| + | IND |

|

|

|

|

|

| B | 233 |

| maintenance work. |

|

|

|

|

|

|

|

|

| Turn the engine or input power OFF before | ||||

W |

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

| B |

|

|

|

| maintenance work unless the maintenance work | |

|

|

| B |

| 237 |

|

|

|

|

|

| requires it to be running. | |

|

|

|

|

|

|

|

| START |

|

| |||

224 |

|

|

|

|

|

|

|

|

| Keep hands, hair, clothing and tools away | |||

| ALTERNATOR |

|

|

|

|

|

|

|

| ||||

|

|

|

|

| + | - |

|

| MOVING | ||||

|

|

|

|

|

|

|

| B |

| from moving parts, and insure all guards or | |||

| U | 222 |

|

|

| AMMETER |

| COLD | PARTS | covers are replaced after servicing. | |||

|

|

|

|

|

|

|

|

| CAN INJURE |

| |||

IDLER | B | 234 | IDLER | G |

|

|

|

| TERMINAL |

| WARNING | ||

SWITCH |

|

|

|

|

|

| |||||||

SOLENOID |

|

| B |

|

|

|

| ||||||

|

|

|

|

|

|

|

|

| |||||

B | 220 | U | 226 |

|

| 5B |

|

|

|

|

| Uncontrolled release of door restraint cords can cause injury. | |

|

|

|

|

|

|

|

| B |

| ||||

| 225 | B | 229 |

|

|

| IGNITION |

|

| Keep secure hold of cord, and keep face away | |||

| 5A |

|

|

|

|

| |||||||

|

|

| G |

|

|

|

|

| from cord when hooking or releasing hook. | ||||

|

|

|

|

|

|

| SWITCH |

|

|

| |||

| B |

|

|

|

|

|

|

|

| 235 |

|

|

|

|

| 1 |

|

|

|

| B 236 |

|

|

|

| MAINTENANCEINSTRUCTIONS | |

|

|

|

|

|

|

|

|

|

|

|

|

| |

1 2 3 4 5 | 6 7 8 9 | 10 2 |

|

|

|

|

|

| B |

|

|

| DAILY CHECKS: |

J1 |

| 3 |

|

| R |

|

|

|

|

|

|

|

|

IDLER/ENGINE | J2 |

|

|

|

|

|

|

|

|

|

| Welding cable connections are tight. | |

4 |

|

|

|

|

|

|

|

|

|

| |||

PROTECTION |

|

|

|

|

|

|

|

|

|

|

|

| |

P.C. BOARD | R |

|

| G |

|

|

|

|

|

|

| All equipment in serviceable condition. | |

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

| 5C |

|

|

|

|

|

|

| Engine oil, coolant, air cleaner and fuel |

|

|

|

|

|

|

|

|

|

|

|

| strainer are at proper operating level and clean. | |

|

|

| W |

|

|

|

|

|

| S | + | + | AS REQUIRED: |

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

| ||

OIL PRESSURE |

| W |

|

|

|

|

|

|

|

|

| Blow dust from machine using clean low pressure air. | |

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

| STARTING |

| Clean commutators or slip rings with fine sandpaper- | |||

SWITCH (N.C.) |

| G |

|

|

|

| B | - | |||||

| TO CONTROL PANEL | MOTOR | - | NOT EMERY CLOTH. See Operating Manual for instructions. | |||||||||

|

|

|

|

|

|

|

|

|

| ||||

|

| 223 | B |

| GROUND SCREW |

|

|

|

| Replace brushes before the pigtails are within 1/4"of | |||

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

| TO TOROID | 1/4" of the commutator. See Operating Manual for instructions. | |

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

| 227 |

|

|

|

| R |

|

|

| |

|

| 221 | B |

|

| B |

|

|

|

| LEAD COLOR CODE | ||

|

| B |

|

|

|

| FUEL SHUT |

| 2 CR |

| |||

|

|

|

|

|

|

|

| OFF VALVE |

| REED RELAY |

| ||

|

| TEMPERATURE GAGE |

|

|

|

|

|

|

|

| |||

|

|

|

|

| G |

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

| ENGINE TEMP. |

| ||

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

| SENSOR |

| |

|

| FUEL INJECTION PUMP |

|

|

|

|

|

|

| ||||

|

|

|

| G |

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| B |

|

|

|

| 11- 01 |

|

|

|

|

|

|

|

|

|

|

|

|

| |

M19233

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual. The specific diagram for a particular code is pasted inside the machine on one of the enclosure panels.