OPERATION | ||

|

|

|

PROCEDURE RECOMMENDATIONS

When properly used, plasma arc cutting is a very eco- nomical process. Improper use will result in a very high operating cost.

General - In All Cases

•Follow safety precautions as printed throughout this operating manual and on the machine.

•If piercing is required, slowly lower the torch at an angle of about 30° to blow the dross away from the torch tip and slowly rotate the torch to a vertical position as the arc becomes deeper. This process will blow a lot of molten metal and dross. Be careful! Blow the dross away from the torch, the operator and any flammable objects.

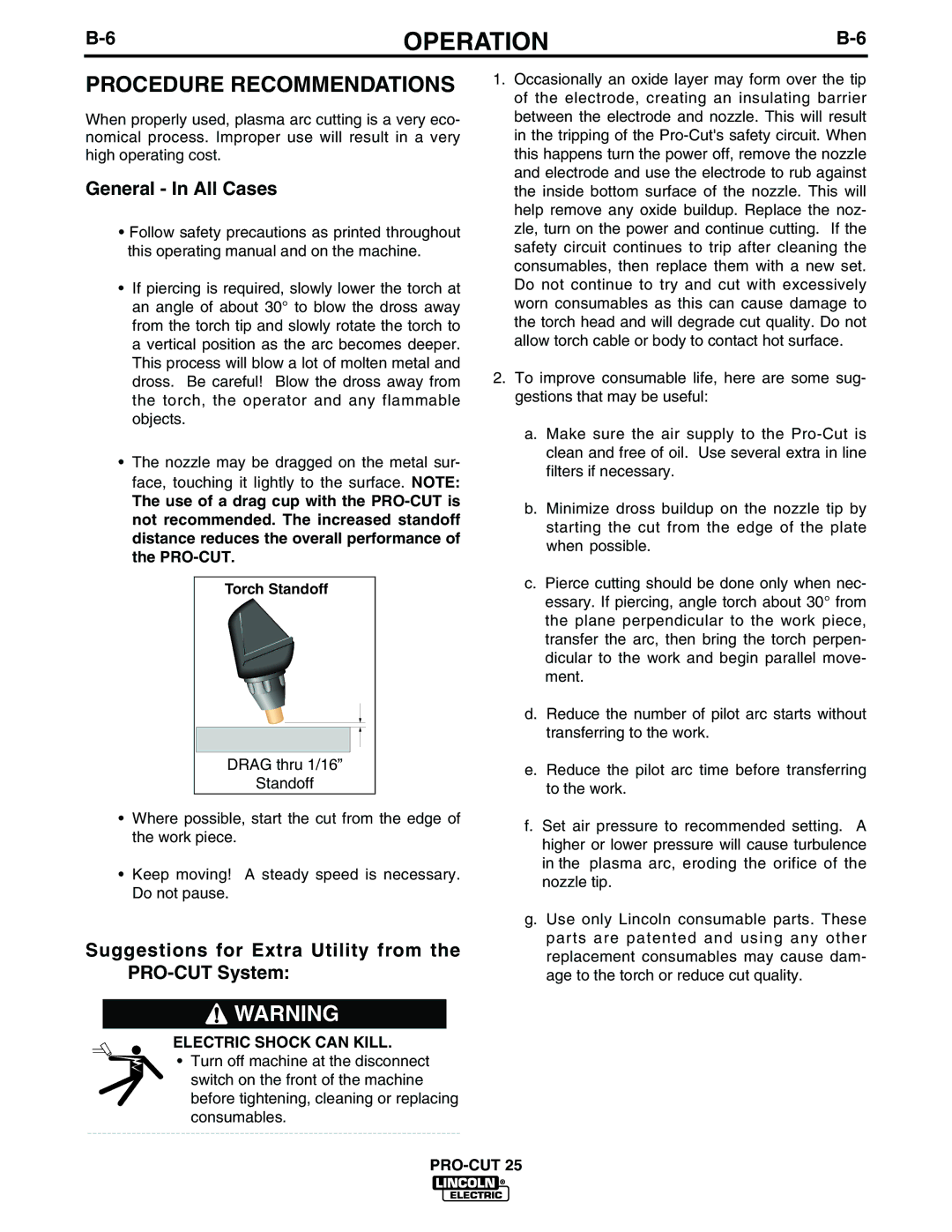

•The nozzle may be dragged on the metal sur- face, touching it lightly to the surface. NOTE:

The use of a drag cup with the

Torch Standoff |

DRAG thru 1/16” |

Standoff |

•Where possible, start the cut from the edge of the work piece.

•Keep moving! A steady speed is necessary. Do not pause.

Suggestions for Extra Utility from the PRO-CUT System:

1.Occasionally an oxide layer may form over the tip of the electrode, creating an insulating barrier between the electrode and nozzle. This will result in the tripping of the

2.To improve consumable life, here are some sug- gestions that may be useful:

a.Make sure the air supply to the

b.Minimize dross buildup on the nozzle tip by starting the cut from the edge of the plate when possible.

c.Pierce cutting should be done only when nec- essary. If piercing, angle torch about 30° from the plane perpendicular to the work piece, transfer the arc, then bring the torch perpen- dicular to the work and begin parallel move- ment.

d.Reduce the number of pilot arc starts without transferring to the work.

e.Reduce the pilot arc time before transferring to the work.

f.Set air pressure to recommended setting. A higher or lower pressure will cause turbulence in the plasma arc, eroding the orifice of the nozzle tip.

g.Use only Lincoln consumable parts. These parts are patented and using any other replacement consumables may cause dam- age to the torch or reduce cut quality.

![]() WARNING

WARNING

ELECTRIC SHOCK CAN KILL.

•Turn off machine at the disconnect switch on the front of the machine before tightening, cleaning or replacing

consumables.