INSTALLATION | ||

|

|

|

SELECT SUITABLE LOCATION

Locate the welder in a dry location where there is free circulation of clean air into the louvers in the back and out the front of the unit. A location that minimizes the amount of smoke and dirt drawn into the rear louvers reduces the chance of dirt accumulation that can block air passages and cause overheating.

STACKING

PRO 100’s cannot be stacked.

TILTING

Each machine must be placed on a secure, level sur- face, either directly or on a recommended undercar- riage. The machine may topple over if this procedure is not followed.

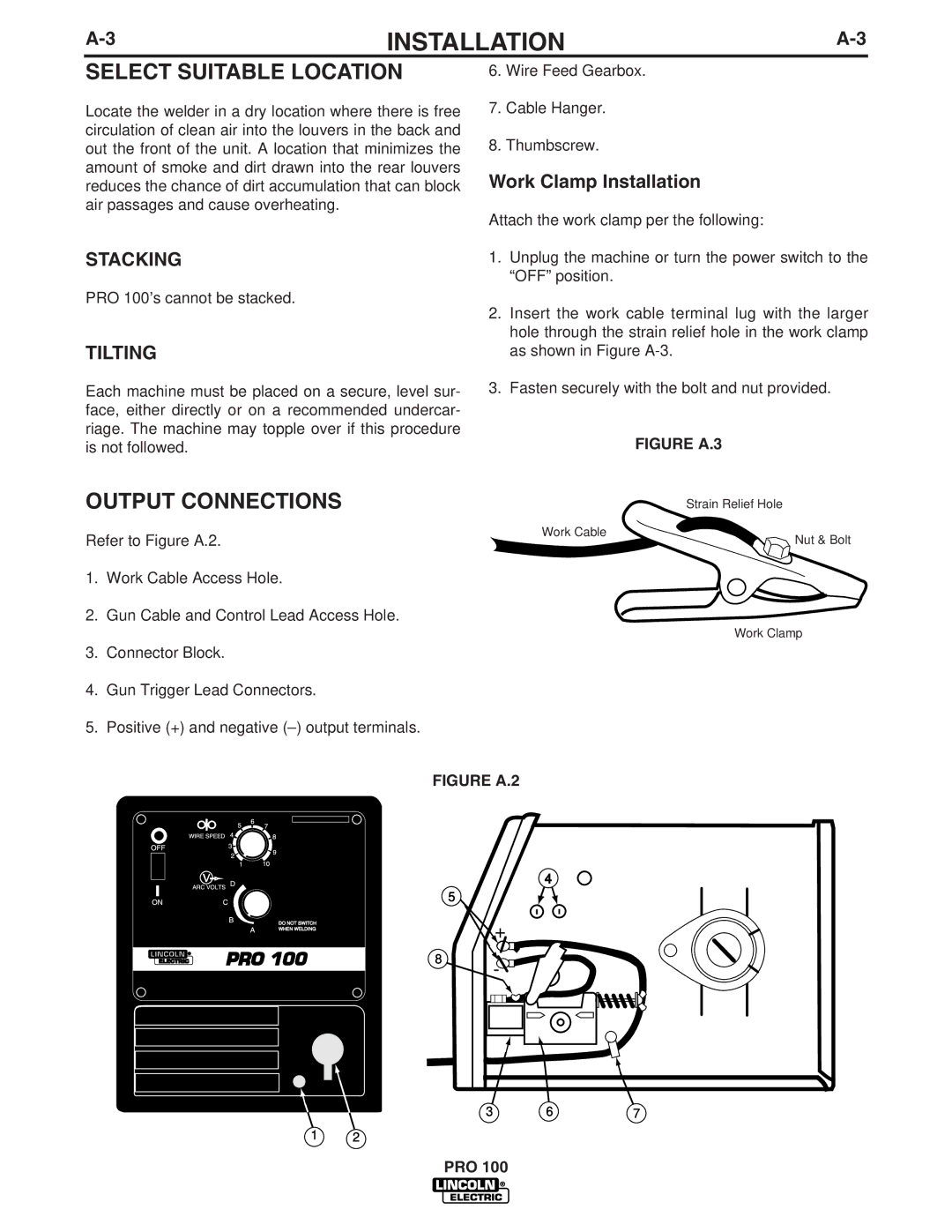

OUTPUT CONNECTIONS

Refer to Figure A.2.

1.Work Cable Access Hole.

2.Gun Cable and Control Lead Access Hole.

6.Wire Feed Gearbox.

7.Cable Hanger.

8.Thumbscrew.

Work Clamp Installation

Attach the work clamp per the following:

1.Unplug the machine or turn the power switch to the “OFF” position.

2.Insert the work cable terminal lug with the larger hole through the strain relief hole in the work clamp as shown in Figure

3.Fasten securely with the bolt and nut provided.

FIGURE A.3

Strain Relief Hole

Work Cable

![]() Nut & Bolt

Nut & Bolt

Work Clamp

3.Connector Block.

4.Gun Trigger Lead Connectors.

5.Positive (+) and negative

FIGURE A.2

DO NOT SWITCH

WHEN WELDING

PRO 100

4

5

![]() +

+

8

-

3 | 6 | 7 |

1 2

PRO 100