INSTALLATION | ||

|

|

|

CONFIGURING THE SYSTEM

For codes below 11100, consult the

For codes above 11100 the power source will “Auto Map” the system eliminating most of the need to set DIP switches to configure the system.

If a system can not be “Auto Mapped” then the status light on the power source will blink green fast and the welder output will be disabled. If a system is not “Auto- mappable”, then consult the instruction manual for the accessory being used for configuration information about DIP switch settings, or consult your local Lincoln sales representative.

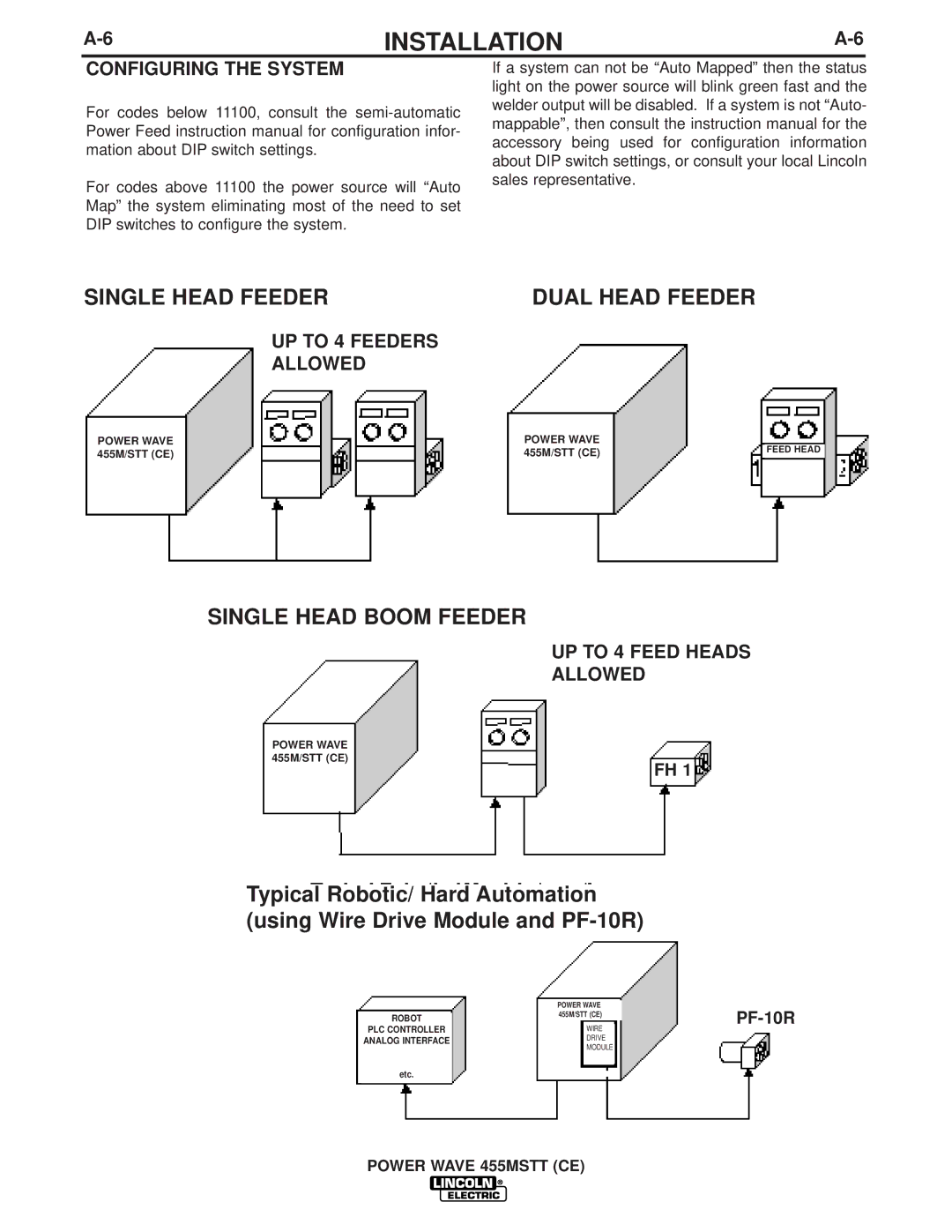

SINGLE HEAD FEEDER | DUAL HEAD FEEDER |

UP TO 4 FEEDERS

ALLOWED

POWER WAVE |

| POWER WAVE |

|

|

455M/STT (CE) |

| 455M/STT (CE) |

| FEED HEAD |

|

|

|

|

|

SINGLE HEAD BOOM FEEDER

UP TO 4 FEED HEADS

ALLOWED

POWER WAVE 455M/STT (CE)

FH 1

Typical Robotic/ Hard Automation

(using Wire Drive Module and

| POWER WAVE | ||

ROBOT | 455M/STT (CE) | ||

|

|

| |

|

|

| |

PLC CONTROLLER |

| WIRE |

|

ANALOG INTERFACE |

| DRIVE |

|

|

| MODULE |

|

|

|

|

|

etc.

POWER WAVE 455MSTT (CE)