|

|

|

|

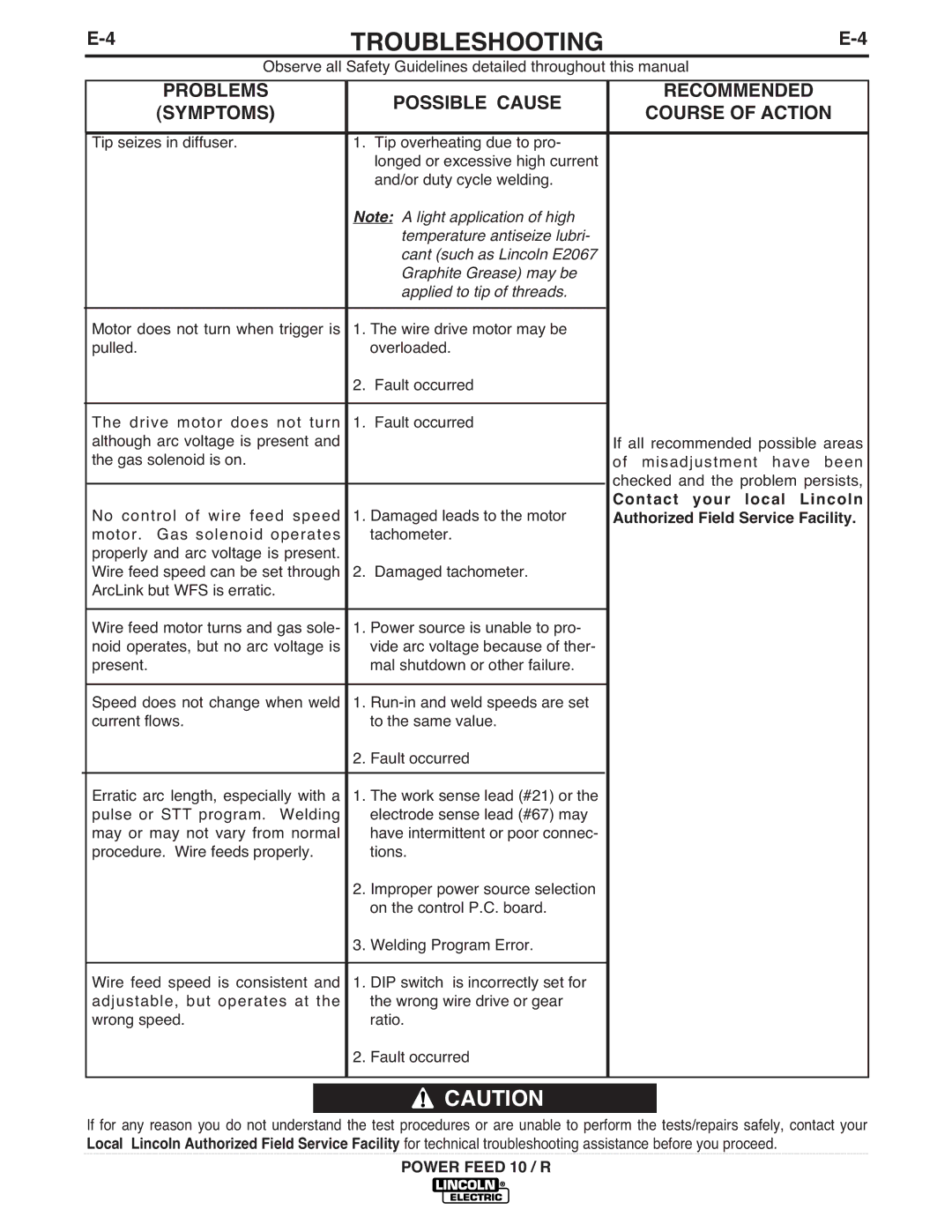

| TROUBLESHOOTING |

|

| ||||||

|

|

| Observe all Safety Guidelines detailed throughout this manual |

| |||||||||

|

| PROBLEMS |

|

| POSSIBLE CAUSE |

| RECOMMENDED |

| |||||

|

|

|

|

|

| ||||||||

|

| (SYMPTOMS) |

|

| COURSE OF ACTION |

| |||||||

| Tip seizes in diffuser. |

|

|

| 1. | Tip overheating due to pro- |

|

|

|

| |||

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

| longed or excessive high current |

|

|

|

| ||

|

|

|

|

|

|

| and/or duty cycle welding. |

|

|

|

| ||

|

|

|

|

|

| Note: A light application of high |

|

|

|

| |||

|

|

|

|

|

|

| temperature antiseize lubri- |

|

|

|

| ||

|

|

|

|

|

|

| cant (such as Lincoln E2067 |

|

|

|

| ||

|

|

|

|

|

|

| Graphite Grease) may be |

|

|

|

| ||

|

|

|

|

|

|

| applied to tip of threads. |

|

|

|

| ||

| Motor does not turn when trigger is | 1. | The wire drive motor may be |

|

|

|

|

| |||||

| pulled. |

|

|

| 2. | overloaded. |

|

|

|

| |||

|

|

|

|

|

| Fault occurred |

|

|

|

| |||

| The drive motor does not turn | 1. | Fault occurred |

| If all recommended possible areas | ||||||||

| although arc voltage is present and |

|

|

|

|

| |||||||

| the gas solenoid is on. |

|

|

|

|

|

|

|

| of misadjustment have been | |||

|

|

|

|

|

|

|

|

|

|

| checked and the problem persists, | ||

| No control of wire feed speed | 1. | Damaged leads to the motor |

| Contact your local Lincoln | ||||||||

|

| Authorized Field Service Facility. | |||||||||||

| motor. Gas solenoid operates |

| tachometer. |

| |||||||||

| properly and arc voltage is present. | 2. | Damaged tachometer. |

|

|

|

| ||||||

| Wire feed speed can be set through |

|

|

|

| ||||||||

| ArcLink but WFS is erratic. |

|

|

|

|

|

|

|

| ||||

| Wire feed motor turns and gas sole- | 1. | Power source is unable to pro- |

|

|

|

| ||||||

| noid operates, but no arc voltage is |

| vide arc voltage because of ther- |

|

|

|

| ||||||

| present. |

|

|

|

| mal shutdown or other failure. |

|

|

|

| |||

| Speed does not change when weld | 1. |

|

|

|

| |||||||

| current flows. |

|

|

| 2. | to the same value. |

|

|

|

| |||

|

|

|

|

|

| Fault occurred |

|

|

|

| |||

| Erratic arc length, especially with a | 1. | The work sense lead (#21) or the |

|

|

|

|

| |||||

| pulse or STT program. Welding |

| electrode sense lead (#67) may |

|

|

|

| ||||||

| may or may not vary from normal |

| have intermittent or poor connec- |

|

|

|

| ||||||

| procedure. Wire feeds properly. | 2. | tions. |

|

|

|

| ||||||

|

|

|

|

|

| Improper power source selection |

|

|

|

| |||

|

|

|

|

|

| 3. | on the control P.C. board. |

|

|

|

| ||

|

|

|

|

|

| Welding Program Error. |

|

|

|

| |||

| Wire feed speed is consistent and | 1. | DIP switch is incorrectly set for |

|

|

|

| ||||||

| adjustable, but operates at the |

| the wrong wire drive or gear |

|

|

|

| ||||||

| wrong speed. |

|

|

| 2. | ratio. |

|

|

|

| |||

|

|

|

|

|

| Fault occurred |

|

|

|

| |||

|

|

|

|

|

|

| CAUTION |

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

| |||

| If for any reason you do not unders | tand the test procedures or are unable to perform the | tests/repairs safely, contact your | ||||||||||

| Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed. |

| |||||||||||

|

|

|

|

|

|

| POWER FEED 10 / R |

|

|

| |||