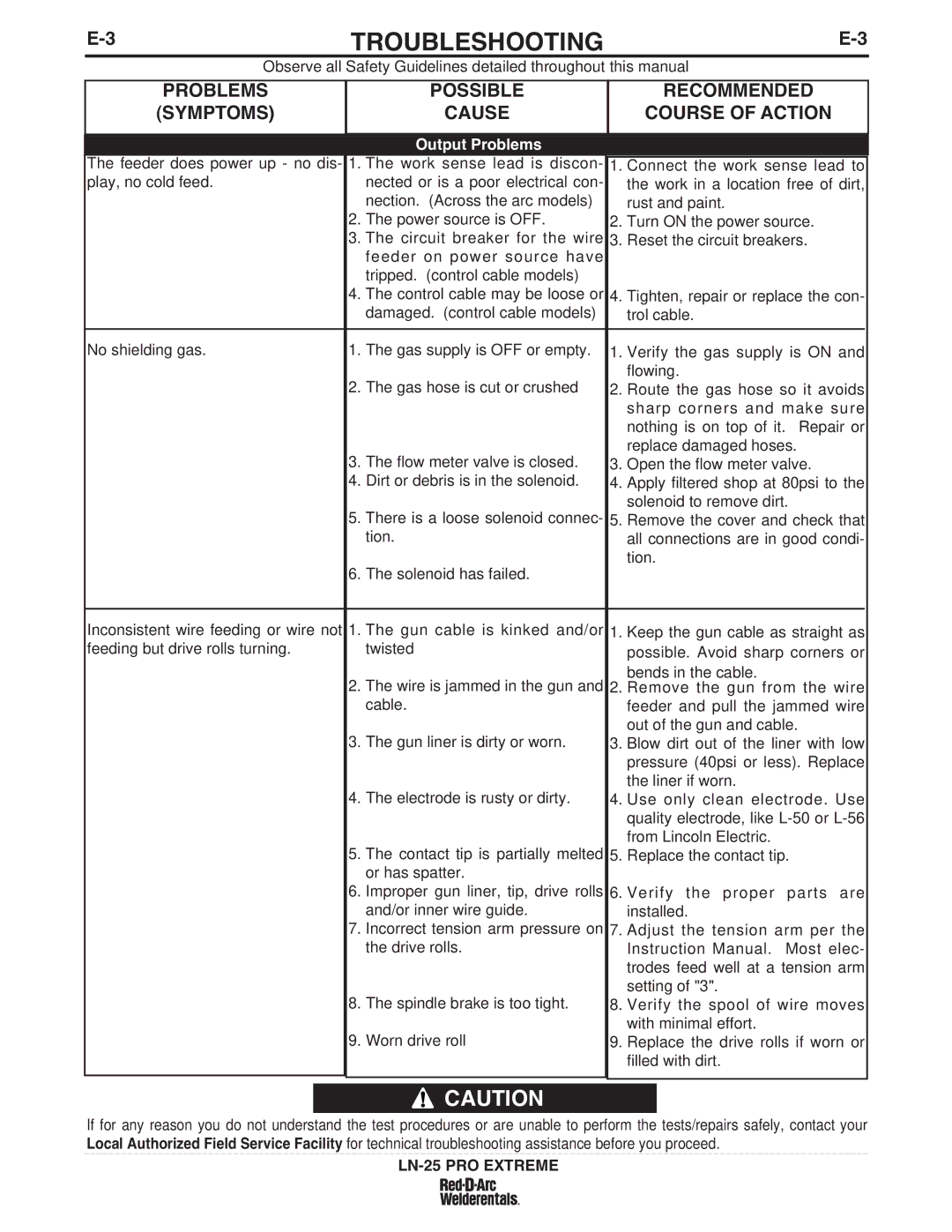

TROUBLESHOOTING | ||

|

|

|

| Observe all Safety Guidelines detailed throughout this manual |

|

|

|

|

PROBLEMS

(SYMPTOMS)

POSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

Output Problems

The feeder does power up - no dis- | 1. | The work sense lead is discon- | 1. | Connect the work sense lead to | ||||||||

play, no cold feed. |

|

| nected or is a poor electrical con- |

| the work in a location free of dirt, | |||||||

|

|

| nection. (Across the arc models) |

| rust and paint. | |||||||

|

| 2. | The power source is OFF. | 2. | Turn ON the power source. | |||||||

|

| 3. | The circuit breaker for the wire | 3. | Reset the circuit breakers. | |||||||

|

|

| feeder on power source have |

|

|

|

| |||||

|

|

| tripped. (control cable models) |

|

|

|

| |||||

|

| 4. | The control cable may be loose or | 4. | Tighten, repair or replace the con- | |||||||

|

|

| damaged. (control cable models) |

| trol cable. | |||||||

|

|

|

|

|

|

|

|

|

| |||

No shielding gas. |

| 1. | The gas supply is OFF or empty. | 1. | Verify the gas supply is ON and | |||||||

|

| 2. | The gas hose is cut or crushed |

| flowing. | |||||||

|

| 2. | Route the gas hose so it avoids | |||||||||

|

|

|

|

|

|

|

|

|

| sharp corners and make sure | ||

|

|

|

|

|

|

|

|

|

| nothing is on top of it. Repair or | ||

|

| 3. | The flow meter valve is closed. |

| replace damaged hoses. | |||||||

|

| 3. | Open the flow meter valve. | |||||||||

|

| 4. | Dirt or debris is in the solenoid. | 4. | Apply filtered shop at 80psi to the | |||||||

|

| 5. | There is a loose solenoid connec- |

| solenoid to remove dirt. | |||||||

|

| 5. | Remove the cover and check that | |||||||||

|

|

| tion. |

| all connections are in good condi- | |||||||

|

| 6. | The solenoid has failed. |

| tion. | |||||||

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

|

| ||||

Inconsistent wire feeding or wire not | 1. | The gun cable is kinked and/or | 1. | Keep the gun cable as straight as | ||||||||

feeding but drive rolls turning. |

|

| twisted |

| possible. Avoid sharp corners or | |||||||

|

| 2. | The wire is jammed in the gun and |

| bends in the cable. | |||||||

|

| 2. | Remove the gun from the wire | |||||||||

|

|

| cable. |

| feeder and pull the jammed wire | |||||||

|

| 3. | The gun liner is dirty or worn. |

| out of the gun and cable. | |||||||

|

| 3. | Blow dirt out of the liner with low | |||||||||

|

|

|

|

|

|

|

|

|

| pressure (40psi or less). Replace | ||

|

| 4. | The electrode is rusty or dirty. |

| the liner if worn. | |||||||

|

| 4. | Use only clean electrode. Use | |||||||||

|

|

|

|

|

|

|

|

|

| quality electrode, like | ||

|

| 5. | The contact tip is partially melted |

| from Lincoln Electric. | |||||||

|

| 5. | Replace the contact tip. | |||||||||

|

|

| or has spatter. |

|

|

|

| |||||

|

| 6. | Improper gun liner, tip, drive rolls | 6. | Verify the proper parts are | |||||||

|

|

| and/or inner wire guide. |

| installed. | |||||||

|

| 7. | Incorrect tension arm pressure on | 7. | Adjust the tension arm per the | |||||||

|

|

| the drive rolls. |

| Instruction Manual. Most elec- | |||||||

|

|

|

|

|

|

|

|

|

| trodes feed well at a tension arm | ||

|

| 8. | The spindle brake is too tight. |

| setting of "3". | |||||||

|

| 8. | Verify the spool of wire moves | |||||||||

|

| 9. | Worn drive roll |

| with minimal effort. | |||||||

|

| 9. | Replace the drive rolls if worn or | |||||||||

|

|

|

|

|

|

|

|

|

| filled with dirt. | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|