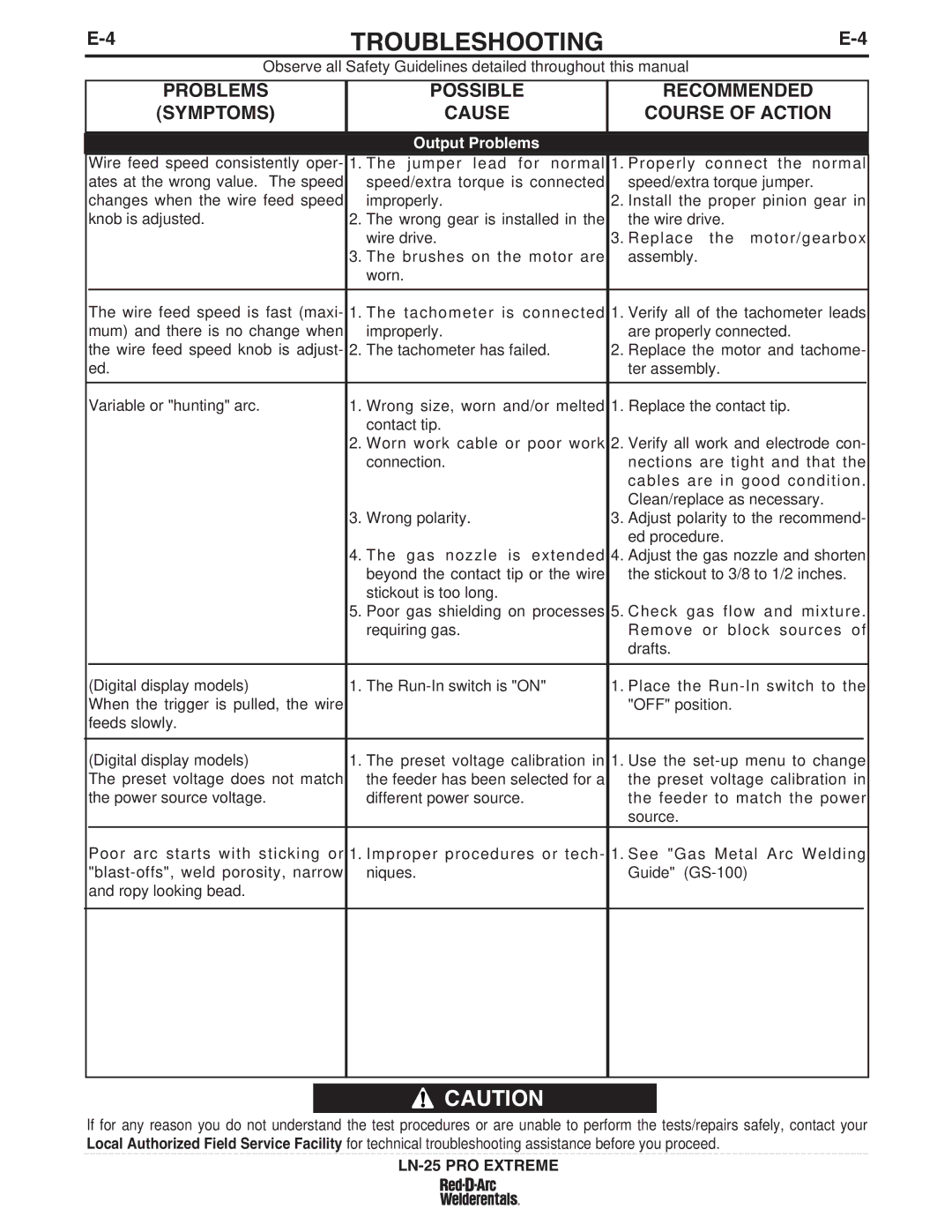

TROUBLESHOOTING | ||

|

|

|

| Observe all Safety Guidelines detailed throughout this manual |

|

|

|

|

PROBLEMS

(SYMPTOMS)

POSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

Output Problems

Wire feed speed consistently oper- | 1. | The jumper lead for normal | 1. | Properly | connect the normal | |

ates at the wrong value. The speed |

| speed/extra torque is connected |

| speed/extra torque jumper. | ||

changes when the wire feed speed |

| improperly. | 2. | Install the proper pinion gear in | ||

knob is adjusted. | 2. | The wrong gear is installed in the |

| the wire drive. | ||

|

| wire drive. | 3. | Replace | the motor/gearbox | |

| 3. The brushes on the motor are |

| assembly. |

|

| |

|

| worn. |

|

|

|

|

|

|

|

|

| ||

The wire feed speed is fast (maxi- | 1. | The tachometer is connected | 1. | Verify all of the tachometer leads | ||

mum) and there is no change when |

| improperly. |

| are properly connected. | ||

the wire feed speed knob is adjust- | 2. | The tachometer has failed. | 2. | Replace the motor and tachome- | ||

ed. |

|

|

| ter assembly. | ||

|

|

|

|

| ||

Variable or "hunting" arc. | 1. | Wrong size, worn and/or melted | 1. Replace the contact tip. | |||

|

| contact tip. |

|

|

|

|

| 2. | Worn work cable or poor work | 2. | Verify all work and electrode con- | ||

|

| connection. |

| nections are tight and that the | ||

|

|

|

| cables are in good condition. | ||

|

|

|

| Clean/replace as necessary. | ||

| 3. | Wrong polarity. | 3. | Adjust polarity to the recommend- | ||

|

|

|

| ed procedure. | ||

| 4. | The gas nozzle is extended | 4. | Adjust the gas nozzle and shorten | ||

|

| beyond the contact tip or the wire |

| the stickout to 3/8 to 1/2 inches. | ||

|

| stickout is too long. |

|

|

|

|

| 5. | Poor gas shielding on processes | 5. | Check gas flow and mixture. | ||

|

| requiring gas. |

| Remove or block sources of | ||

|

|

|

| drafts. |

|

|

|

|

|

|

|

| |

(Digital display models) | 1. | The | 1. | Place the | ||

When the trigger is pulled, the wire |

|

|

| "OFF" position. | ||

feeds slowly. |

|

|

|

|

|

|

|

|

|

|

|

| |

(Digital display models) | 1. | The preset voltage calibration in | 1. | Use the | ||

The preset voltage does not match |

| the feeder has been selected for a |

| the preset voltage calibration in | ||

the power source voltage. |

| different power source. |

| the feeder to match the power | ||

|

|

|

| source. |

|

|

Poor arc starts with sticking or | 1. Improper procedures or tech- | 1. See "Gas Metal Arc Welding | ||||

| niques. |

| Guide" | |||

and ropy looking bead. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Authorized Field Service Facility for technical troubleshooting assistance before you proceed.