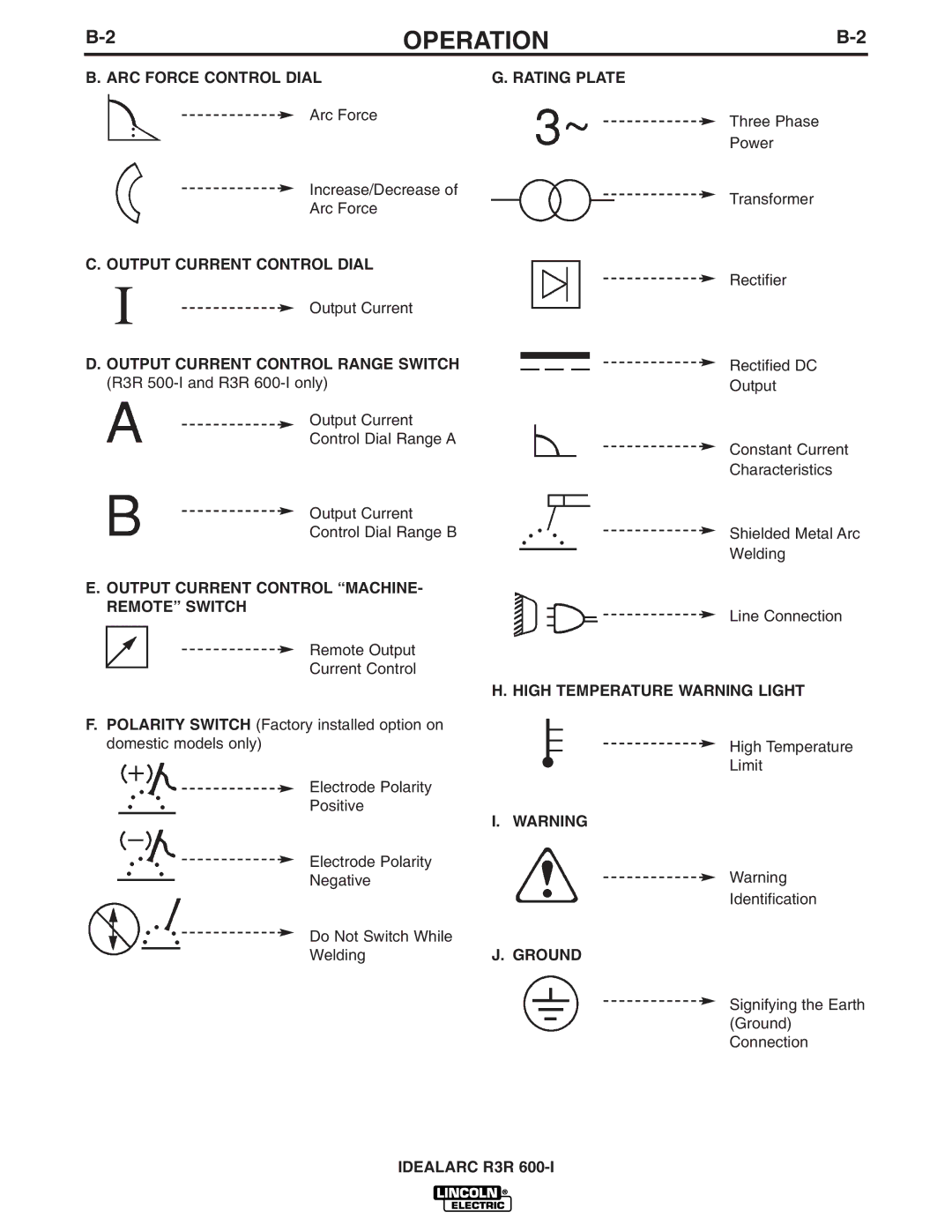

B-2 OPERATIONB-2

B. ARC FORCE CONTROL DIAL

Arc Force

Increase/Decrease of

Arc Force

C. OUTPUT CURRENT CONTROL DIAL

Output Current

D. OUTPUT CURRENT CONTROL RANGE SWITCH (R3R

Output Current

Control Dial Range A

Output Current

Control Dial Range B

E.OUTPUT CURRENT CONTROL “MACHINE- REMOTE” SWITCH

Remote Output

Current Control

F.POLARITY SWITCH (Factory installed option on domestic models only)

Electrode Polarity

Positive

Electrode Polarity

Negative

Do Not Switch While

Welding

G. RATING PLATE

Three Phase

Power

Transformer

Rectifier

Rectified DC

Output

Constant Current

Characteristics

Shielded Metal Arc

Welding

Line Connection

H. HIGH TEMPERATURE WARNING LIGHT

High Temperature

Limit

I. WARNING

Warning

Identification

J. GROUND

Signifying the Earth (Ground) Connection

IDEALARC R3R