INSTALLATION | ||

|

|

|

CONTACT TIP AND DIFFUSER

INSTALLATION

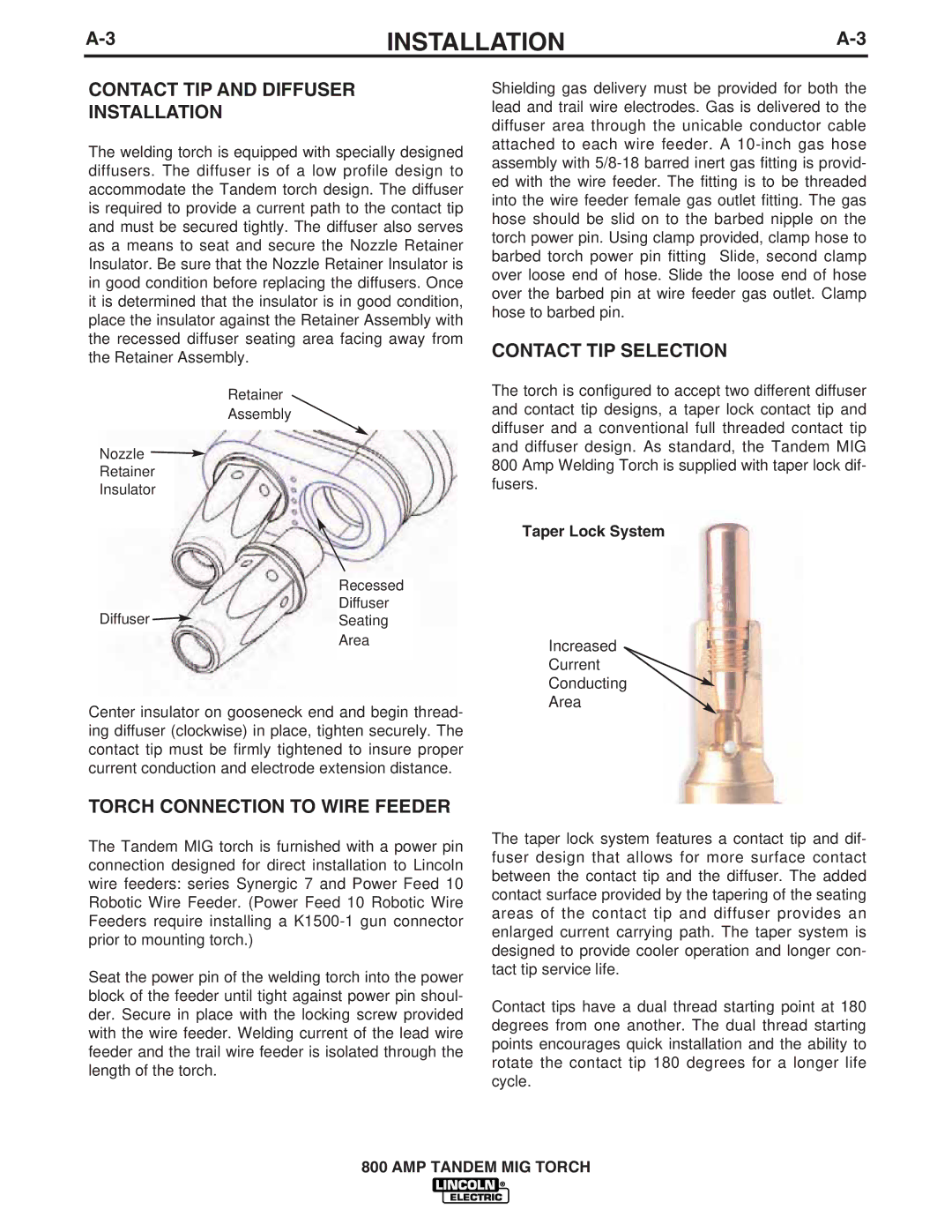

The welding torch is equipped with specially designed diffusers. The diffuser is of a low profile design to accommodate the Tandem torch design. The diffuser is required to provide a current path to the contact tip and must be secured tightly. The diffuser also serves as a means to seat and secure the Nozzle Retainer Insulator. Be sure that the Nozzle Retainer Insulator is in good condition before replacing the diffusers. Once it is determined that the insulator is in good condition, place the insulator against the Retainer Assembly with the recessed diffuser seating area facing away from the Retainer Assembly.

Retainer

Assembly

Nozzle ![]()

Retainer

Insulator

|

| Recessed |

|

| Diffuser |

Diffuser |

| Seating |

|

| Area |

| ||

|

|

|

Center insulator on gooseneck end and begin thread- ing diffuser (clockwise) in place, tighten securely. The contact tip must be firmly tightened to insure proper current conduction and electrode extension distance.

TORCH CONNECTION TO WIRE FEEDER

The Tandem MIG torch is furnished with a power pin connection designed for direct installation to Lincoln wire feeders: series Synergic 7 and Power Feed 10 Robotic Wire Feeder. (Power Feed 10 Robotic Wire Feeders require installing a

Seat the power pin of the welding torch into the power block of the feeder until tight against power pin shoul- der. Secure in place with the locking screw provided with the wire feeder. Welding current of the lead wire feeder and the trail wire feeder is isolated through the length of the torch.

Shielding gas delivery must be provided for both the lead and trail wire electrodes. Gas is delivered to the diffuser area through the unicable conductor cable attached to each wire feeder. A

CONTACT TIP SELECTION

The torch is configured to accept two different diffuser and contact tip designs, a taper lock contact tip and diffuser and a conventional full threaded contact tip and diffuser design. As standard, the Tandem MIG 800 Amp Welding Torch is supplied with taper lock dif- fusers.

Taper Lock System

Increased

Current

Conducting

Area

The taper lock system features a contact tip and dif- fuser design that allows for more surface contact between the contact tip and the diffuser. The added contact surface provided by the tapering of the seating areas of the contact tip and diffuser provides an enlarged current carrying path. The taper system is designed to provide cooler operation and longer con- tact tip service life.

Contact tips have a dual thread starting point at 180 degrees from one another. The dual thread starting points encourages quick installation and the ability to rotate the contact tip 180 degrees for a longer life cycle.

800 AMP TANDEM MIG TORCH