TROUBLESHOOTING | ||

|

|

|

| Observe all Safety Guidelines detailed throughout this manual |

|

|

|

|

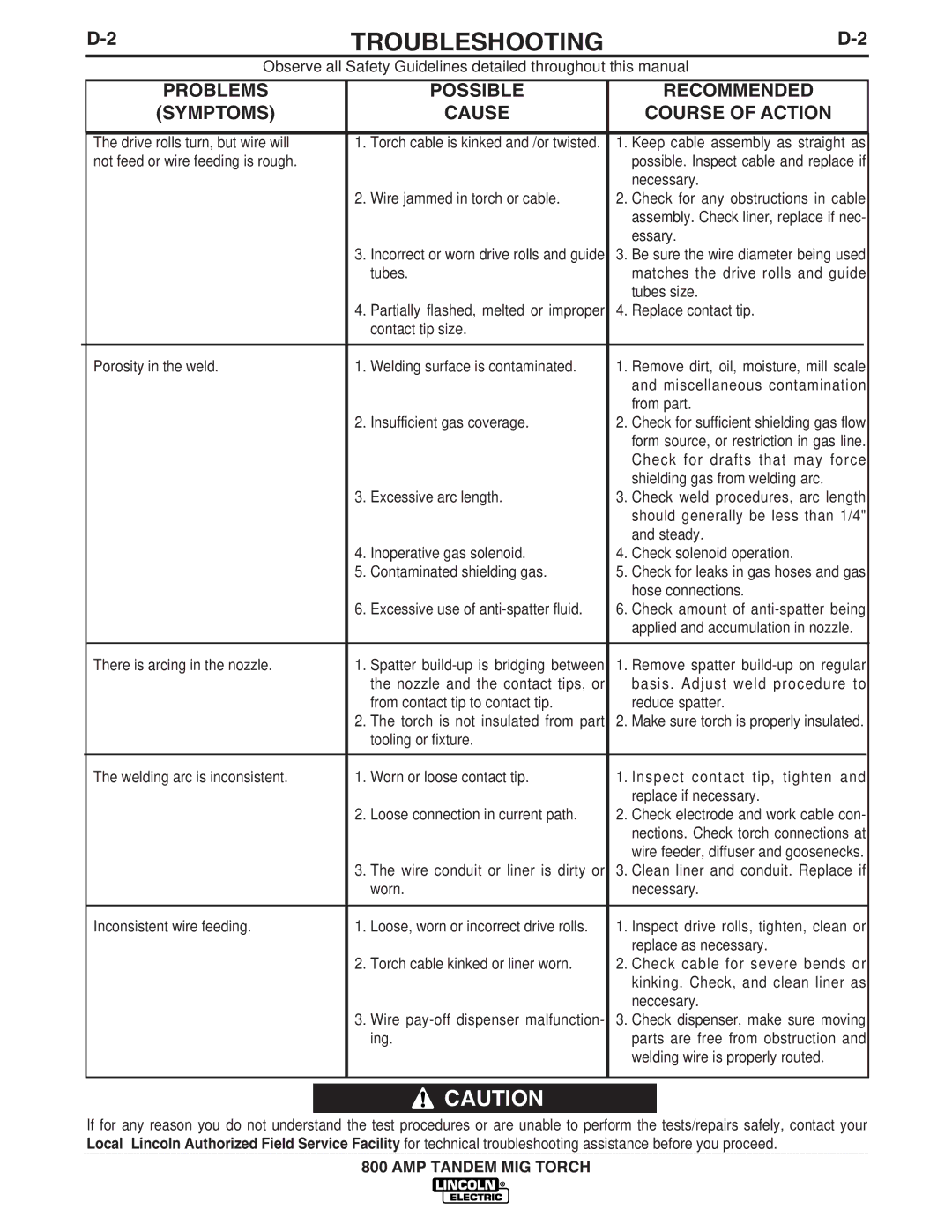

PROBLEMS

(SYMPTOMS)

POSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

| The drive rolls turn, but wire will |

| 1. Torch cable is kinked and /or twisted. | 1. | Keep cable assembly as straight as | |||

| not feed or wire feeding is rough. |

|

|

|

| possible. Inspect cable and replace if | ||

|

|

|

|

|

| necessary. | ||

|

|

| 2. | Wire jammed in torch or cable. | 2. | Check for any obstructions in cable | ||

|

|

|

|

|

| assembly. Check liner, replace if nec- | ||

|

|

|

|

|

| essary. | ||

|

|

| 3. | Incorrect or worn drive rolls and guide | 3. | Be sure the wire diameter being used | ||

|

|

|

| tubes. |

| matches the drive rolls and guide | ||

|

|

|

|

|

| tubes size. | ||

|

|

| 4. | Partially flashed, melted or improper | 4. | Replace contact tip. | ||

|

|

|

| contact tip size. |

|

|

|

|

|

|

|

|

|

|

| ||

| Porosity in the weld. |

| 1. Welding surface is contaminated. | 1. | Remove dirt, oil, moisture, mill scale | |||

|

|

|

|

|

| and miscellaneous contamination | ||

|

|

|

|

|

| from part. | ||

|

|

| 2. | Insufficient gas coverage. | 2. | Check for sufficient shielding gas flow | ||

|

|

|

|

|

| form source, or restriction in gas line. | ||

|

|

|

|

|

| Check for drafts that may force | ||

|

|

|

|

|

| shielding gas from welding arc. | ||

|

|

| 3. | Excessive arc length. | 3. | Check weld procedures, arc length | ||

|

|

|

|

|

| should generally be less than 1/4" | ||

|

|

|

|

|

| and steady. | ||

|

|

| 4. | Inoperative gas solenoid. | 4. | Check solenoid operation. | ||

|

|

| 5. | Contaminated shielding gas. | 5. | Check for leaks in gas hoses and gas | ||

|

|

|

|

|

| hose connections. | ||

|

|

| 6. | Excessive use of | 6. | Check amount of | ||

|

|

|

|

|

| applied and accumulation in nozzle. | ||

|

|

|

|

|

| |||

| There is arcing in the nozzle. |

| 1. Spatter | 1. | Remove spatter | |||

|

|

|

| the nozzle and the contact tips, or |

| basis. Adjust weld procedure to | ||

|

|

|

| from contact tip to contact tip. |

| reduce spatter. | ||

|

|

| 2. | The torch is not insulated from part | 2. | Make sure torch is properly insulated. | ||

|

|

|

| tooling or fixture. |

|

|

|

|

|

|

|

|

|

| |||

| The welding arc is inconsistent. |

| 1. Worn or loose contact tip. | 1. | Inspect contact tip, tighten and | |||

|

|

|

|

|

| replace if necessary. | ||

|

|

| 2. | Loose connection in current path. | 2. | Check electrode and work cable con- | ||

|

|

|

|

|

| nections. Check torch connections at | ||

|

|

|

|

|

| wire feeder, diffuser and goosenecks. | ||

|

|

| 3. | The wire conduit or liner is dirty or | 3. | Clean liner and conduit. Replace if | ||

|

|

|

| worn. |

| necessary. | ||

|

|

|

|

|

| |||

| Inconsistent wire feeding. |

| 1. Loose, worn or incorrect drive rolls. | 1. | Inspect drive rolls, tighten, clean or | |||

|

|

|

|

|

| replace as necessary. | ||

|

|

| 2. | Torch cable kinked or liner worn. | 2. | Check cable for severe bends or | ||

|

|

|

|

|

| kinking. Check, and clean liner as | ||

|

|

|

|

|

| neccesary. | ||

|

|

| 3. | Wire | 3. | Check dispenser, make sure moving | ||

|

|

|

| ing. |

| parts are free from obstruction and | ||

|

|

|

|

|

| welding wire is properly routed. | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| CAUTION |

|

|

|

|

|

|

|

|

|

|

|

|

|

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

800 AMP TANDEM MIG TORCH