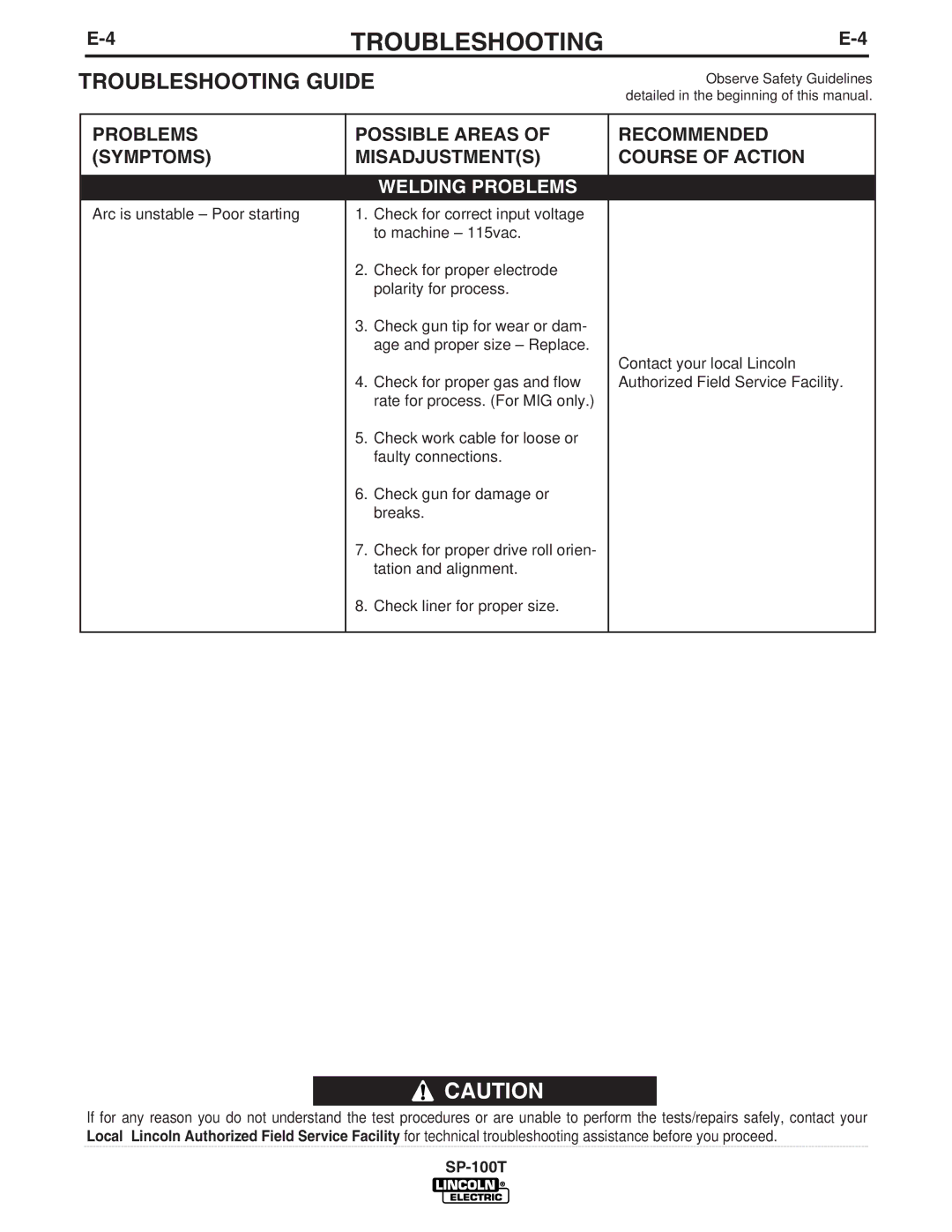

TROUBLESHOOTING |

TROUBLESHOOTING GUIDE

Observe Safety Guidelines detailed in the beginning of this manual.

|

|

|

|

|

|

|

|

|

|

| PROBLEMS |

|

| POSSIBLE AREAS OF |

|

| RECOMMENDED |

| |

| (SYMPTOMS) |

|

| MISADJUSTMENT(S) |

|

| COURSE OF ACTION |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| WELDING PROBLEMS |

|

|

|

|

| Arc is unstable – Poor starting |

|

| 1. Check for correct input voltage |

|

|

|

| |

|

|

|

|

| to machine – 115vac. |

|

|

|

|

|

|

|

| 2. | Check for proper electrode |

|

|

|

|

|

|

|

|

| polarity for process. |

|

|

|

|

|

|

|

| 3. | Check gun tip for wear or dam- |

|

|

|

|

|

|

|

|

| age and proper size – Replace. |

|

| Contact your local Lincoln |

|

|

|

|

| 4. | Check for proper gas and flow |

|

|

| |

|

|

|

|

|

| Authorized Field Service Facility. |

| ||

|

|

|

|

| rate for process. (For MIG only.) |

|

|

|

|

|

|

|

| 5. | Check work cable for loose or |

|

|

|

|

|

|

|

|

| faulty connections. |

|

|

|

|

|

|

|

| 6. | Check gun for damage or |

|

|

|

|

|

|

|

|

| breaks. |

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

| 7. | Check for proper drive roll orien- |

|

|

|

|

|

|

|

|

| tation and alignment. |

|

|

|

|

|

|

|

| 8. | Check liner for proper size. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.