OPERATION | ||

|

|

|

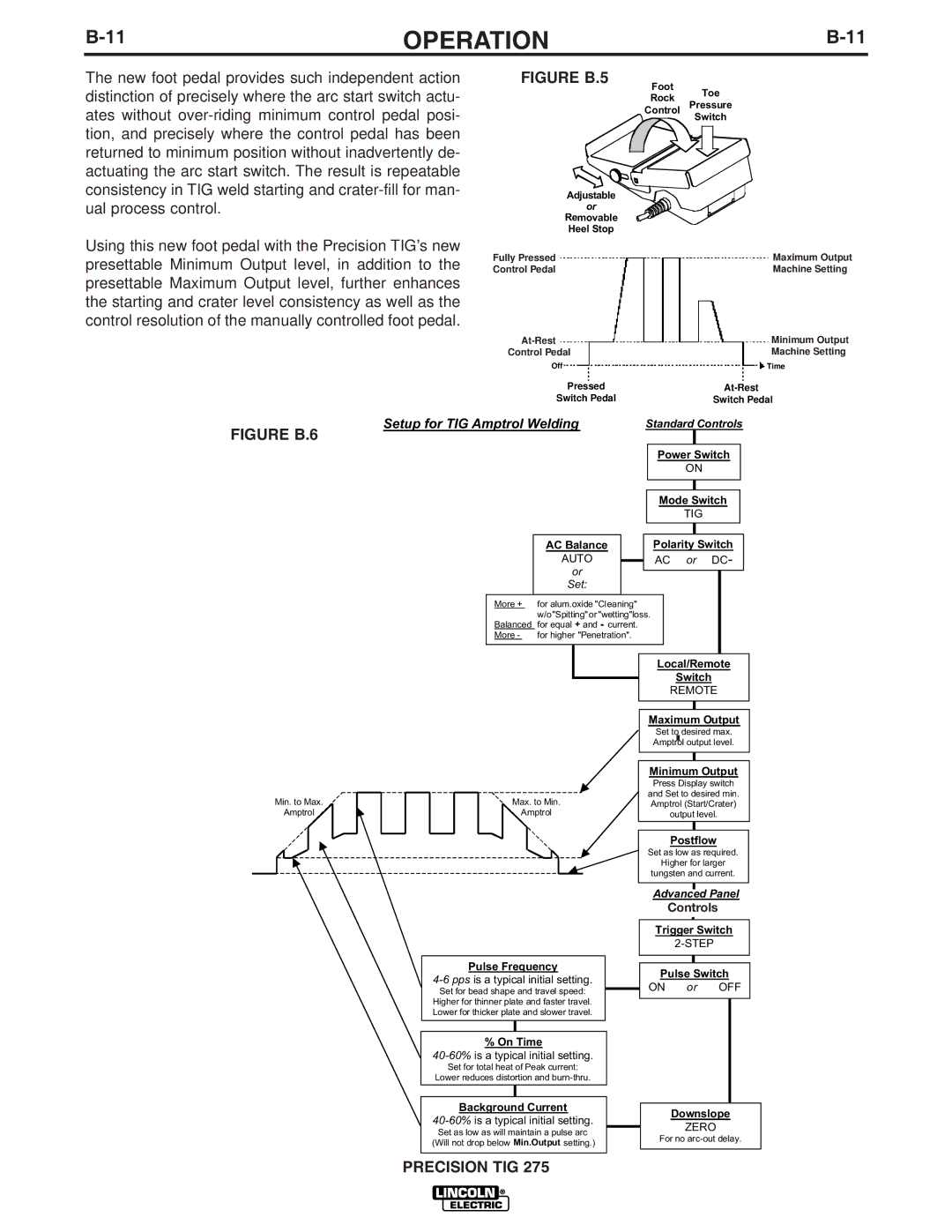

The new foot pedal provides such independent action distinction of precisely where the arc start switch actu- ates without

Using this new foot pedal with the Precision TIG’s new presettable Minimum Output level, in addition to the presettable Maximum Output level, further enhances the starting and crater level consistency as well as the control resolution of the manually controlled foot pedal.

FIGURE B.5

Foot

Rock Toe

Control Pressure

Switch

| Adjustable |

|

| |||||

|

|

| ||||||

| or |

|

|

|

|

|

| |

|

|

| ||||||

| Removable |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| Heel Stop | |||||||

Fully Pressed |

|

|

|

|

|

|

| Maximum Output |

Control Pedal |

|

|

|

|

|

|

| Machine Setting |

|

|

| Minimum Output | ||||

Control Pedal |

|

| Machine Setting | ||||

|

|

|

|

|

|

| |

|

| Off |

|

| Tim | e | |

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

| Pressed | ||||

|

| Switch Pedal | Switch Pedal | ||||

|

|

|

| ||||

Setup for TIG Amptrol Welding

FIGURE B.6

AC Balance

AUTO

or

Set:

Standard Controls

Power Switch

ON

Mode Switch

TIG

Polarity Switch

AC or DC-

More + for alum.oxide "Cleaning" w/o"Spitting" or "wetting"loss.

Balanced for equal + and - current. More - for higher "Penetration".

Min. to Max. ![]() Amptrol

Amptrol ![]()

Max. to Min.

![]() Amptrol

Amptrol

Pulse Frequency

4-6 pps is a typical initial setting.

Set for bead shape and travel speed: Higher for thinner plate and faster travel. Lower for thicker plate and slower travel.

% On Time

Set for total heat of Peak current:

Lower reduces distortion and

Background Current

Set as low as will maintain a pulse arc (Will not drop below Min.Output setting.)

Local/Remote

Switch

REMOTE

Maximum Output

Set to desired max. Amptrol output level.

Minimum Output

Press Display switch

and Set to desired min. Amptrol (Start/Crater) output level.

Postflow

Set as low as required.

Higher for larger

tungsten and current.

Advanced Panel

Controls(If used)

Trigger Switch

Pulse Switch

ON or OFF

Downslope

ZERO

For no