150 - 500 specifications

Lochinvar has established itself as a leader in the field of hydronic heating solutions, and the Lochinvar 150 - 500 series is a prime example of its commitment to innovation and efficiency. Designed primarily for commercial applications, this line of high-efficiency boilers is engineered to provide optimized performance, reliability, and cost-effectiveness.One of the standout features of the Lochinvar 150 - 500 series is its robust construction. Built with a durable stainless-steel heat exchanger, these boilers offer superior resistance to corrosion, ensuring a longer lifespan and consistent performance over time. The advanced design of the heat exchanger also maximizes heat transfer, contributing to higher efficiency ratings.

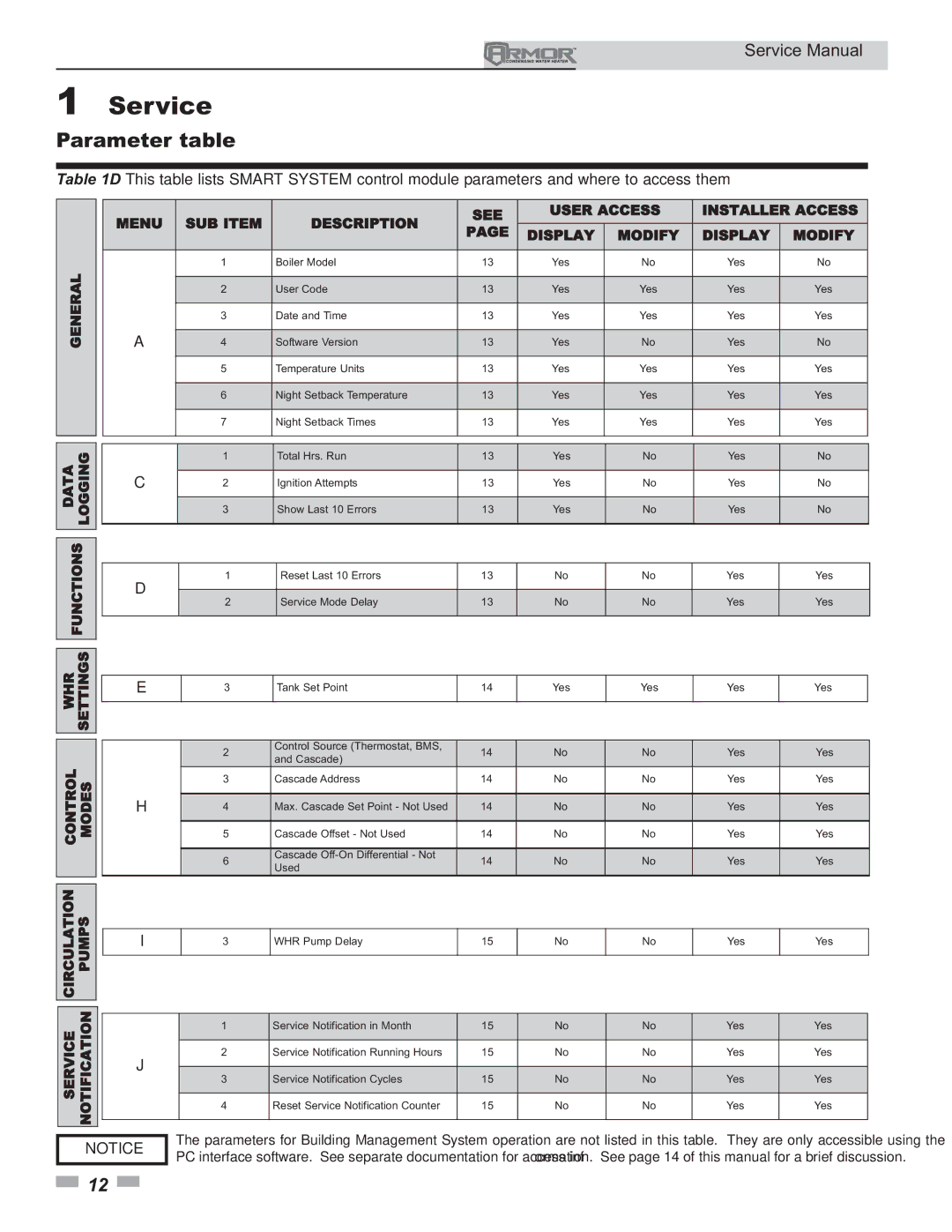

In terms of technology, the Lochinvar 150 - 500 series incorporates the Concentric Venting System, which allows for flexible installation options and reduces the overall footprint required for the boiler setup. This system is particularly advantageous in commercial settings where space can be limited. The boilers are equipped with smart controls that provide real-time monitoring and diagnostics, allowing for easier maintenance and reducing downtime.

The series features a comprehensive modulation range, allowing the boilers to adjust their output based on the heating demand. This capability not only enhances efficiency but also lowers energy consumption, making it an eco-friendly choice for businesses seeking to reduce their environmental impact. The Lochinvar 150 - 500 boilers utilize innovative combustion technologies, including an integrated burner that ensures optimal combustion efficiency and reduced emissions.

Safety is a priority with the Lochinvar 150 - 500 series, which includes multiple safety features such as lockout protection, pressure switches, and high-temperature limit controls. These measures ensure that the unit operates safely under varying conditions, providing peace of mind for operators.

Additionally, the compact design of the Lochinvar 150 - 500 series allows for easy transportation and installation. Its lightweight structure enables it to be maneuvered through tight spaces typically found in commercial buildings, making it a versatile option for installers.

In summary, the Lochinvar 150 - 500 series is an excellent choice for anyone seeking a reliable, efficient, and technologically advanced boiler solution. With its durable construction, advanced features, and commitment to safety and efficiency, this series stands out as a trusted option in the competitive market of hydronic heating systems.