399 - 800 specifications

Lochinvar is known for its cutting-edge water heating and boiler systems, and the Lochinvar 399 - 800 series is no exception. Specifically designed for commercial applications, this series brings advanced technology and engineering to the forefront of hydronic heating solutions.One of the standout features of the Lochinvar 399 - 800 series is its impressive efficiency. Equipped with a condensing design, these boilers utilize high-efficiency stainless steel heat exchangers that allow for maximum heat transfer while minimizing energy consumption. With an impressive thermal efficiency of up to 96%, the Lochinvar 399 - 800 series stands out in its class, offering significant energy savings and reduced operational costs over time.

Another key characteristic of this series is its robust construction. Designed with longevity in mind, the boilers are built using high-quality materials that withstand extreme temperatures and pressures. The stainless steel design not only enhances durability but also combats corrosion, ensuring a long service life and reduced maintenance costs for users.

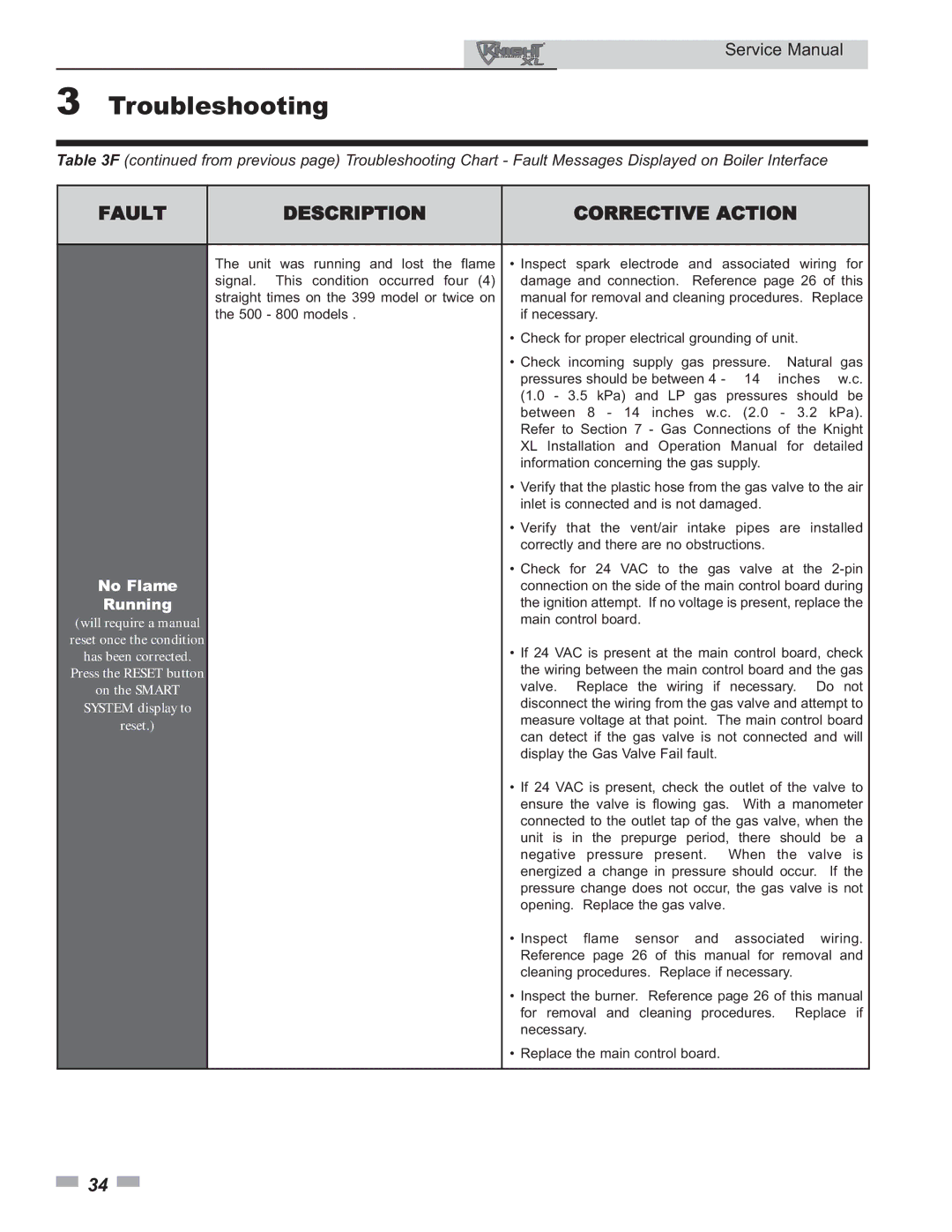

The Lochinvar 399 - 800 series also incorporates advanced control technologies. With its intuitive control system, users can easily adjust and monitor heating parameters, ensuring optimal performance and comfort. The integrated Control Wizard feature simplifies the setup process, allowing for quick commissioning and troubleshooting. Additionally, the optional Lochinvar SMART CONTROL technology provides remote monitoring capabilities, allowing operators to keep track of system performance from anywhere.

Versatility is another hallmark of the Lochinvar 399 - 800 series. These boilers come in a range of sizes, with the ability to modulate output based on real-time heating demands. This flexibility ensures that systems can operate efficiently under varying load conditions, making them ideal for schools, hospitals, and commercial buildings requiring consistent hot water availability.

In summary, the Lochinvar 399 - 800 series exemplifies modern boiler technology, combining energy efficiency, durability, advanced controls, and versatility. As businesses and facilities seek to enhance their heating systems, the Lochinvar 399 - 800 offers a reliable and forward-thinking solution for today's energy-conscious environment. Investing in this state-of-the-art boiler system not only improves comfort but also fosters sustainability and cost-effectiveness in commercial heating applications.