RPV-I&S specifications

Lochinvar RPV-I&S (Remote Pressure Vessel – Inspection & Safety) is a remarkable innovation in the realm of heating technology, designed to enhance performance, safety, and efficiency in residential and commercial applications. This cutting-edge system integrates advanced features and technologies that cater to the demands of modern energy requirements.A standout feature of the Lochinvar RPV-I&S is its robust construction, ensuring durability and longevity. The unit is built with high-quality materials that can withstand significant pressure and temperature variations. This durability not only guarantees long-term performance but also minimizes maintenance, making it a cost-effective solution for users.

One of the key characteristics of the RPV-I&S is its remote monitoring capability. This technology allows users to oversee the system's performance from anywhere, providing real-time data on pressure levels, temperature, and overall efficiency. This feature not only enhances user convenience but also enables proactive maintenance, reducing the likelihood of unexpected failures.

The RPV-I&S employs state-of-the-art safety mechanisms. It is equipped with multiple fail-safes and alarm systems designed to detect anomalies in the system's operation. If unsafe conditions arise, the system can automatically shut down, preventing potential hazards. This focus on safety ensures peace of mind for both operators and end-users.

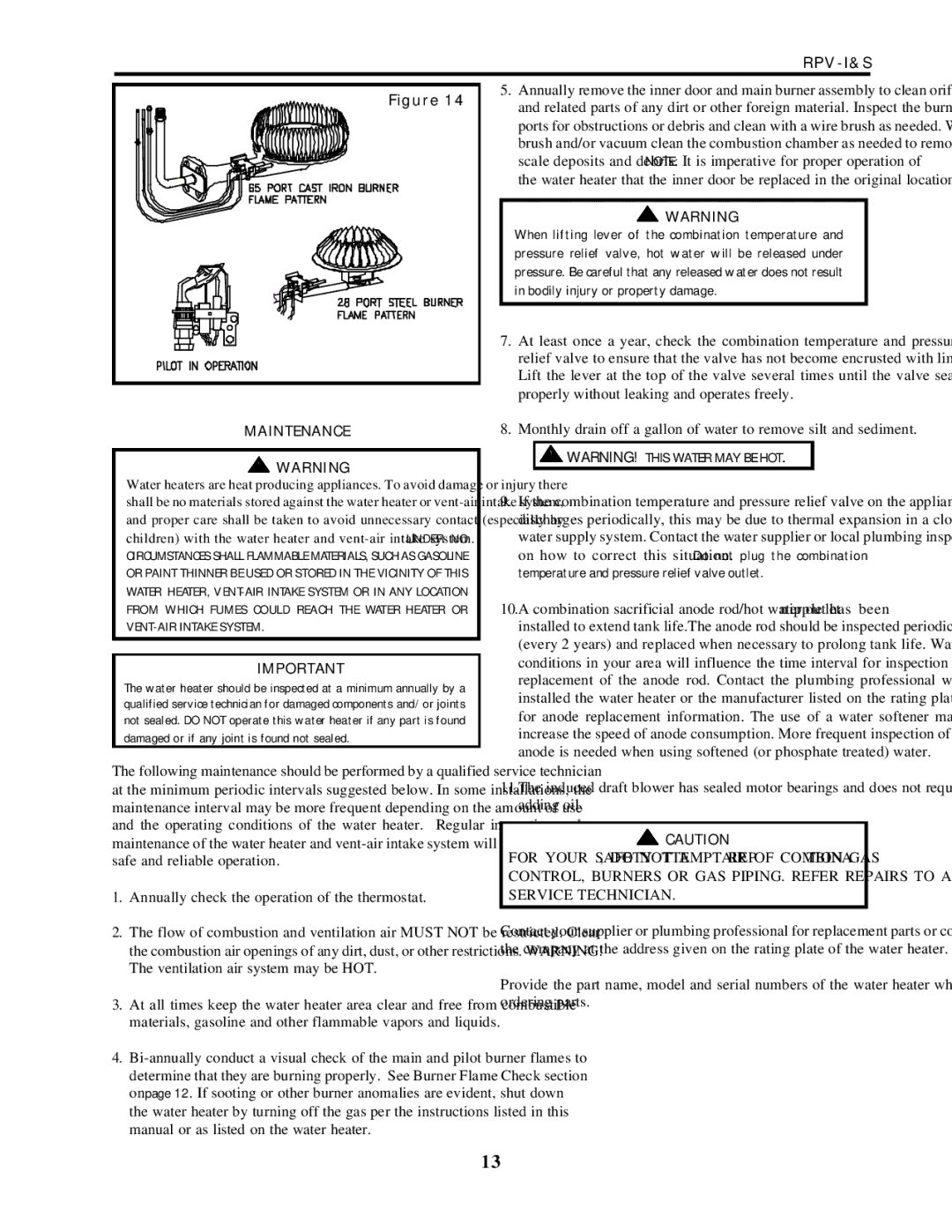

Efficiency is another hallmark of the Lochinvar RPV-I&S. The unit utilizes advanced burner technologies to maximize energy output while minimizing waste. This efficient operation aids in reducing energy bills and contributes to environmental sustainability by lowering carbon emissions. Users can expect substantial energy savings over the unit's lifespan.

Furthermore, the RPV-I&S accommodates a variety of fuel types, including natural gas, propane, and electric options, providing flexibility to users based on their specific needs and energy source availability.

With a user-friendly interface, the Lochinvar RPV-I&S ensures easy operation and adjustment of settings. Its intuitive controls facilitate quick temperature adjustments and system programming, making it accessible for users of all technical backgrounds.

In summary, the Lochinvar RPV-I&S stands out as a technologically advanced, efficient, and safe solution for heating applications. Its combination of robust construction, remote monitoring capabilities, enhanced safety features, and flexible fuel options positions it as a leader in the industry, catering to the evolving demands of today’s energy landscape.