3 Technology, installation and commissioning

Clamp ring screw connections | Figure |

|

■Cut the copper pipe to length and deburr.

■First, slide the clamp ring nut over the pipe, then slide the clamp ring.

■Insert the prepared pipe into the screw connection until its stop is reached.

■Tighten clamp ring nut by hand.

■Use

■When tightening the clamp ring screw connection, use two

Flat seal screw connections

■All

Torque levels when tightening flat seal screw connections using AFM 34 flat seals, s = 2mm.

–3/4" screw connection 26 Ft. lb

–1" screw connection 40 Ft. lb

–1 1/4" screw connection 66 Ft. lb

–1 1/2" screw connection 96 Ft. lb

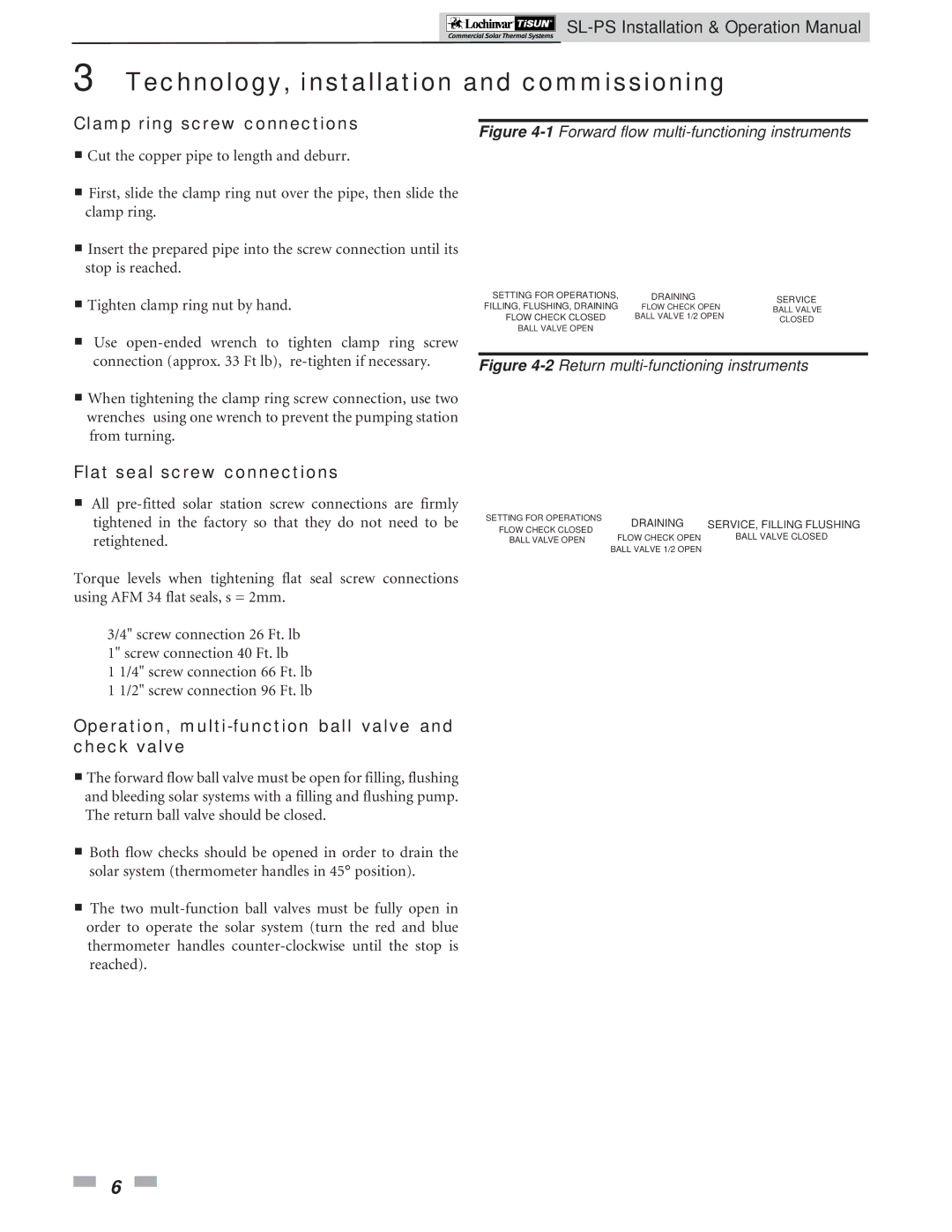

Operation, multi-function ball valve and check valve

■The forward flow ball valve must be open for filling, flushing and bleeding solar systems with a filling and flushing pump. The return ball valve should be closed.

■Both flow checks should be opened in order to drain the solar system (thermometer handles in 45° position).

■The two

SETTING FOR OPERATIONS, | DRAINING | SERVICE |

FILLING, FLUSHING, DRAINING | FLOW CHECK OPEN | BALL VALVE |

FLOW CHECK CLOSED | BALL VALVE 1/2 OPEN | CLOSED |

BALL VALVE OPEN |

|

|

Figure 4-2 Return multi-functioning instruments

SETTING FOR OPERATIONS | DRAINING | SERVICE, FILLING FLUSHING | |

FLOW CHECK CLOSED | |||

FLOW CHECK OPEN | BALL VALVE CLOSED | ||

BALL VALVE OPEN | |||

| BALL VALVE 1/2 OPEN |

|

6