Repair

[3]ASSEMBLING/ DISASSEMBLING

ASSEMBLING

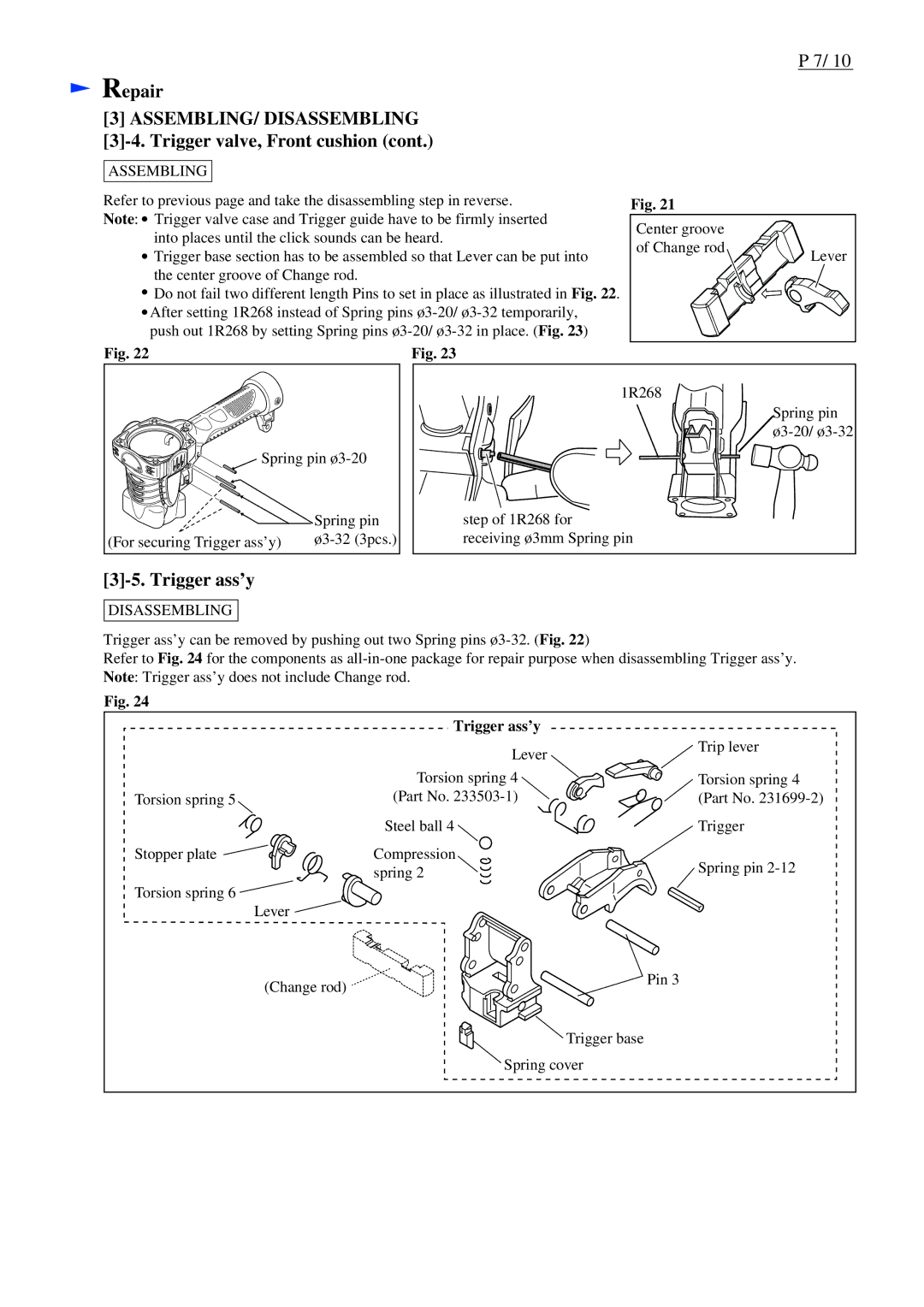

Refer to previous page and take the disassembling step in reverse. Note: ![]() Trigger valve case and Trigger guide have to be firmly inserted

Trigger valve case and Trigger guide have to be firmly inserted

into places until the click sounds can be heard.

![]() Trigger base section has to be assembled so that Lever can be put into the center groove of Change rod.

Trigger base section has to be assembled so that Lever can be put into the center groove of Change rod.

![]() Do not fail two different length Pins to set in place as illustrated in Fig. 22.

Do not fail two different length Pins to set in place as illustrated in Fig. 22. ![]() After setting 1R268 instead of Spring pins

After setting 1R268 instead of Spring pins

P 7/ 10

Fig. 21

Center groove |

|

of Change rod | Lever |

|

Fig. 22

Spring pin | |

| Spring pin |

(For securing Trigger ass’y) | |

Fig. 23

1R268 |

Spring pin |

step of 1R268 for |

receiving ø3mm Spring pin |

[3]-5. Trigger ass’y

DISASSEMBLING

Trigger ass’y can be removed by pushing out two Spring pins

Refer to Fig. 24 for the components as

Fig. 24

| Trigger ass’y |

|

| Lever | Trip lever |

|

| |

| Torsion spring 4 | Torsion spring 4 |

Torsion spring 5 | (Part No. | (Part No. |

| Steel ball 4 | Trigger |

Stopper plate | Compression | Spring pin |

| spring 2 | |

|

| |

Torsion spring 6 |

|

|

| Lever |

|

| (Change rod) | Pin 3 |

|

| |

| Trigger base |

|

| Spring cover |

|