P 3/ 12

![]() Repair

Repair

[3]DISASSEMBLY/ASSEMBLY

[3]-1. Drill Chuck (cont.)

ASSEMBLING

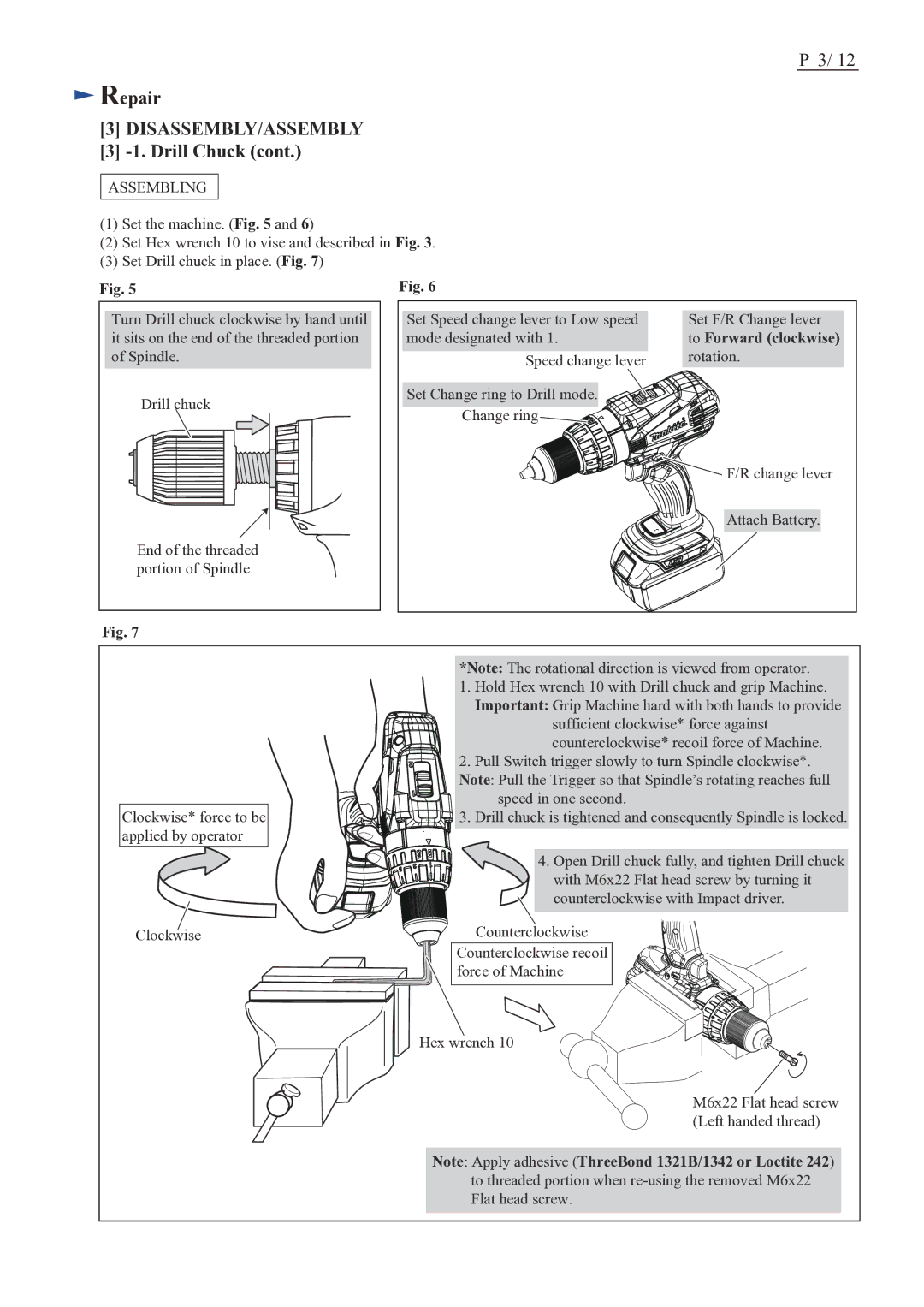

(1)Set the machine. (Fig. 5 and 6)

(2)Set Hex wrench 10 to vise and described in Fig. 3.

(3)Set Drill chuck in place. (Fig. 7)

Fig. 5

Turn Drill chuck clockwise by hand until it sits on the end of the threaded portion of Spindle.

Drill chuck

End of the threaded portion of Spindle

Fig. 6

Set Speed change lever to Low speed | Set F/R Change lever |

mode designated with 1. | to Forward (clockwise) |

Speed change lever | rotation. |

Set Change ring to Drill mode. |

|

Change ring |

|

| F/R change lever |

| Attach Battery. |

Fig. 7

*Note: The rotational direction is viewed from operator.

1.Hold Hex wrench 10 with Drill chuck and grip Machine. Important: Grip Machine hard with both hands to provide sufficient clockwise* force against

counterclockwise* recoil force of Machine.

2.Pull Switch trigger slowly to turn Spindle clockwise*. Note: Pull the Trigger so that Spindle’s rotating reaches full

speed in one second.

Clockwise* force to be | 3. Drill chuck is tightened and consequently Spindle is locked. |

applied by operator |

|

| 4. Open Drill chuck fully, and tighten Drill chuck |

| with M6x22 Flat head screw by turning it |

| counterclockwise with Impact driver. |

Clockwise | Counterclockwise |

| Counterclockwise recoil |

| force of Machine |

Hex wrench 10

M6x22 Flat head screw (Left handed thread)

Note: Apply adhesive (ThreeBond 1321B/1342 or Loctite 242) to threaded portion when