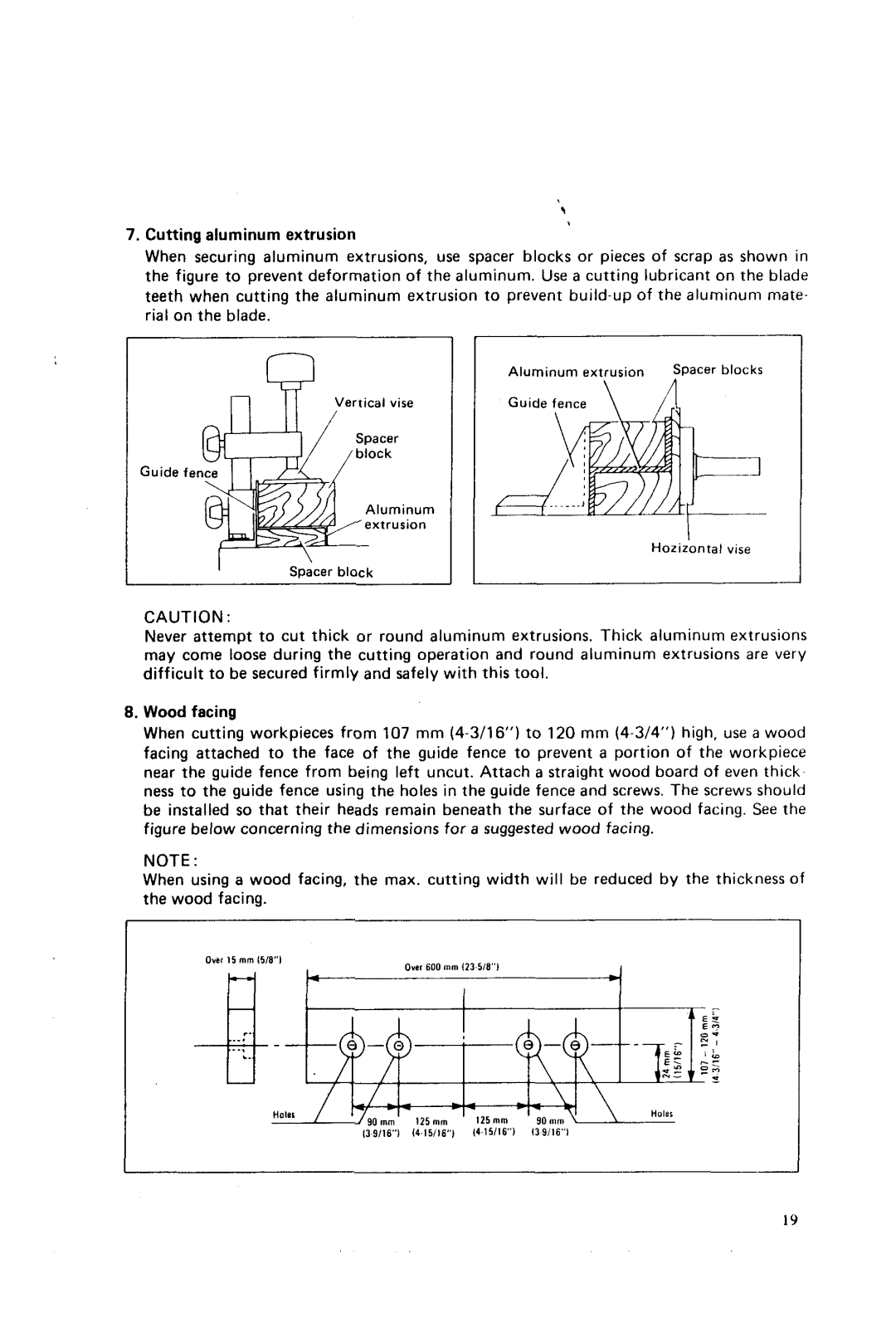

7.Cutting aluminum extrusion

When securing aluminum extrusions, use spacer blocks or pieces of scrap as shown in the figure to prevent deformation of the aluminum. Use a cutting lubricant on the blade teeth when cutting the aluminum extrusion to prevent

n

Guide fe

Aluminum extrusion Spacer blocks

Vertical vise

Horizontal vise

ISpacer black

CAUTION:

Never attempt to cut thick or round aluminum extrusions. Thick aluminum extrusions may come loose during the cutting operation and round aluminum extrusions are very difficult to be secured firmly and safely with this tool.

8.Wood facing

When cutting workpieces from 107 mm

NOTE :

When using a wood facing, the max. cutting width will be reduced by the thickness of the wood facing.

Over 15 m m 1518"l

Over 600 mm 123 518"l

C

(39/16") |

| I4 1 5 / 1 6 ) | 139116"l |

19