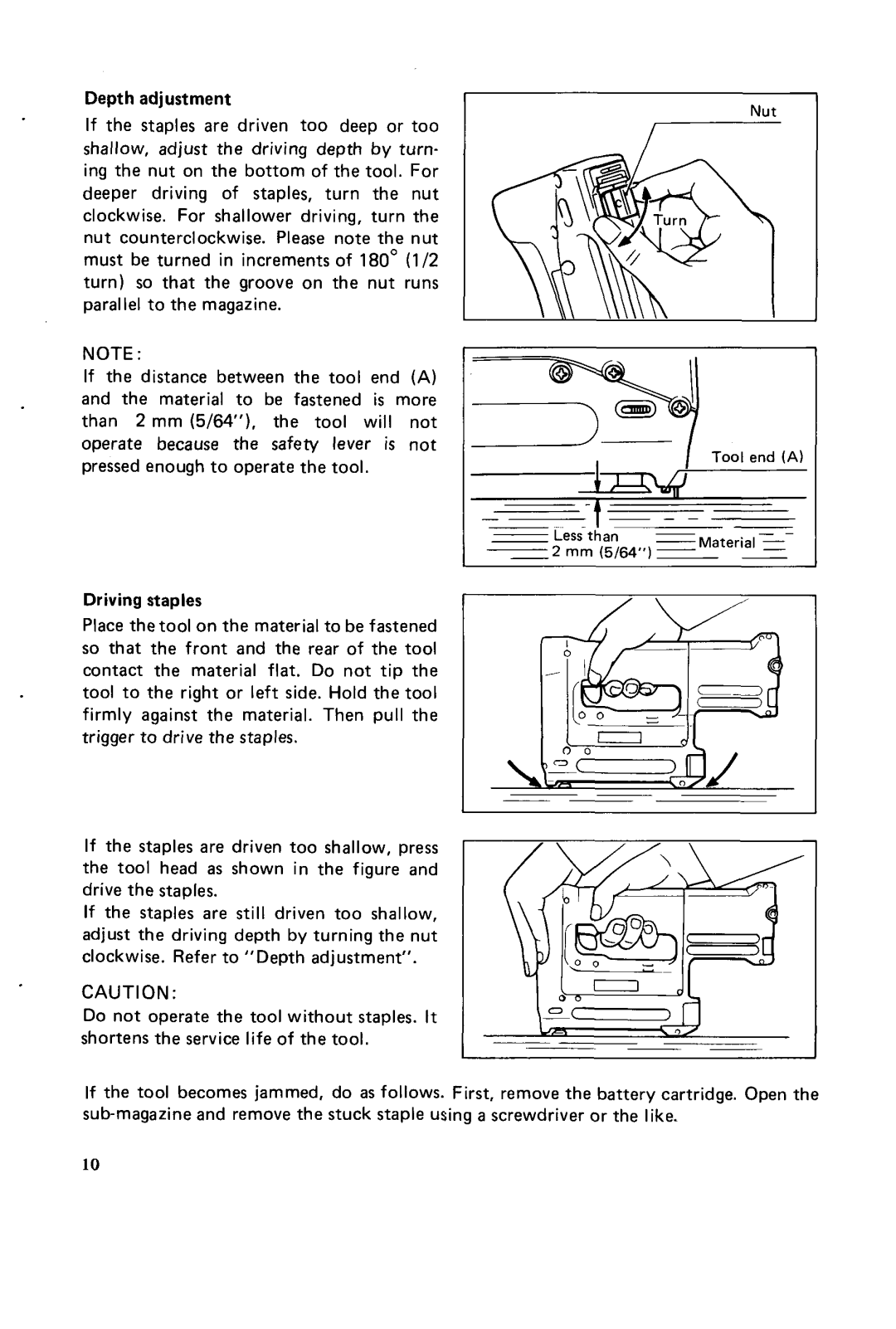

Depth adjustment

If the staples are driven too deep or too shallow, adjust the driving depth by turn- ing the nut on the bottom of the tool. For deeper driving of staples, turn the nut clockwise. For shallower driving, turn the nut counterclockwise. Please note the nut must be turned in increments of 180" (1/2 turn) so that the groove on the nut runs parallel to the magazine.

NOTE :

If the distance between the tool end (A) and the material to be fastened is more than 2 mm (5/64"), the tool will not operate because the safety lever is not pressed enough to operate the tool.

INut

| / Tool end ( A ) |

2 mm (5/64") | Material |

- |

Driving staples

Place the tool on the material to be fastened so that the front and the rear of the tool contact the material flat. Do not tip the tool to the right or left side. Hold the tool firmly against the material. Then pull the trigger to drive the staples.

If the staples are driven too shallow, press the tool head as shown in the figure and drive the staples.

If the staples are still driven too shallow, adjust the driving depth by turning the nut clockwise. Refer to "Depth adjustment".

CAUTION:

Do not operate the tool without staples. It shortens the service life of the tool.

If the tool becomes jammed, do as follows. First, remove the battery cartridge. Open the

10