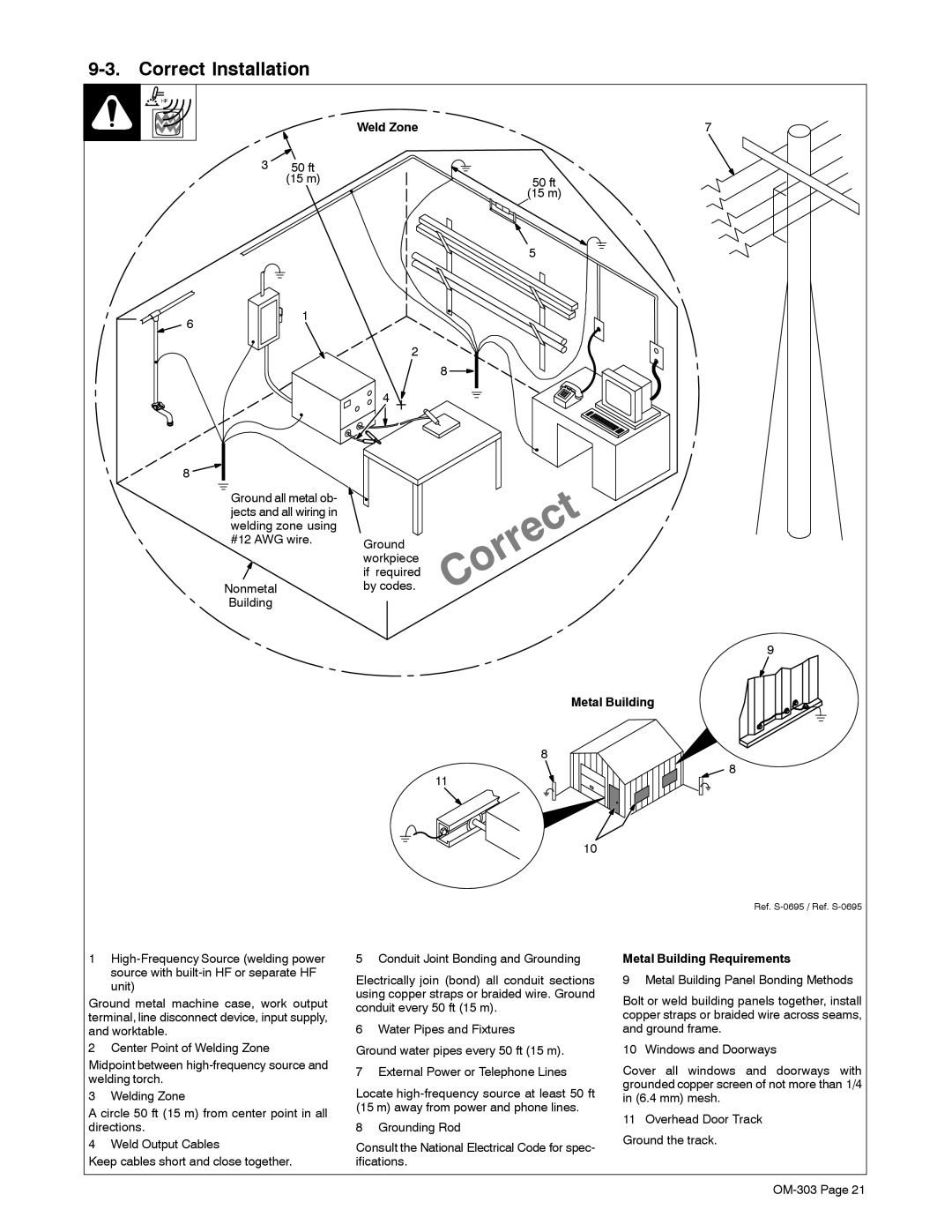

9-3. Correct Installation

Weld Zone

350 ft

(15 m)

7

50ft

(15 m)

5

61

8 ![]()

![]()

![]()

Ground all metal ob- jects and all wiring in welding zone using #12 AWG wire.

Nonmetal

Building

2

8

4

Ground workpiece if required by codes.

11

9

Metal Building

8

8

10

Ref.

1 | 5 Conduit Joint Bonding and Grounding | Metal Building Requirements | ||

| source with | Electrically join (bond) all conduit sections | 9 Metal Building Panel Bonding Methods | |

| unit) | |||

| using copper straps or braided wire. Ground | Bolt or weld building panels together, install | ||

Ground metal machine case, work output | ||||

conduit every 50 ft (15 m). | ||||

terminal, line disconnect device, input supply, | copper straps or braided wire across seams, | |||

| ||||

and worktable. | 6 Water Pipes and Fixtures | and ground frame. | ||

2 Center Point of Welding Zone | Ground water pipes every 50 ft (15 m). | 10 Windows and Doorways | ||

Midpoint between | 7 External Power or Telephone Lines | Cover all windows and doorways with | ||

welding torch. | ||||

Locate | grounded copper screen of not more than 1/4 | |||

3 | Welding Zone | |||

in (6.4 mm) mesh. | ||||

A circle 50 ft (15 m) from center point in all | (15 m) away from power and phone lines. | 11 Overhead Door Track | ||

directions. | 8 Grounding Rod | |||

Ground the track. | ||||

4 | Weld Output Cables | Consult the National Electrical Code for spec- | ||

| ||||

Keep cables short and close together. | ifications. |

| ||