10.Fit tubing provided into the proper place, as shown. Make sure that the discharge line ends up on the inside of the suction line. Cut ice machine suction line to fit new tubing. Deburr suction line before fitting new tubing in.

NOTE: IF REPLACING COMPRESSOR INTO A REMOTE CONDENSER ICE MACHINE, MAKE SURE TO FIRST FOLLOW THE INSTRUCTIONS A, B, AND C BELOW BEFORE PROCEEDING TO INSTRUCTION #11.

A.Cut process tubing approximately 3” from the horizontal portion of the tube. Make sure to cut both ends of the tube to make sure that a “T” fitting can be placed in between the pieces.

Approx. 3”

Horizontal

Portion

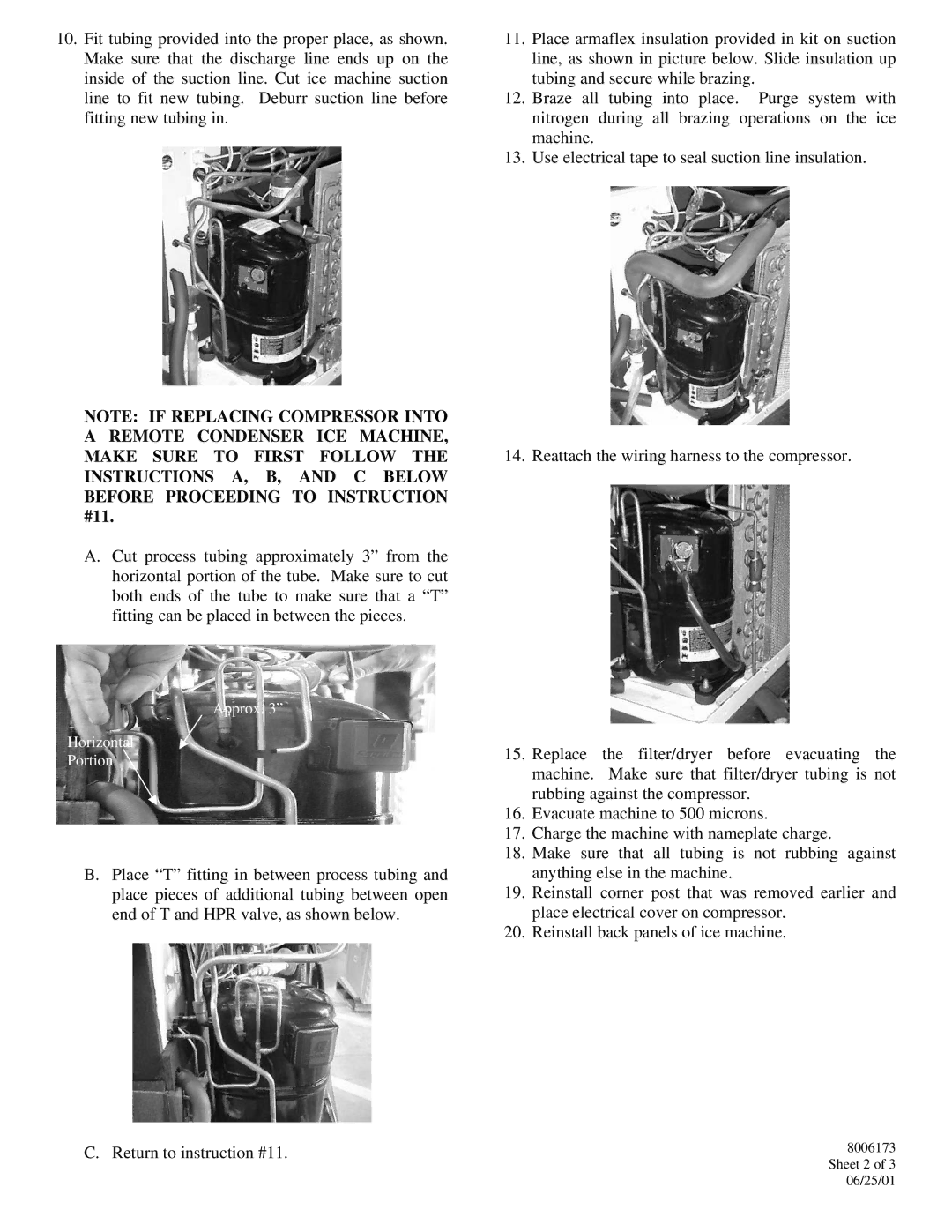

B.Place “T” fitting in between process tubing and place pieces of additional tubing between open end of T and HPR valve, as shown below.

11.Place armaflex insulation provided in kit on suction line, as shown in picture below. Slide insulation up tubing and secure while brazing.

12.Braze all tubing into place. Purge system with nitrogen during all brazing operations on the ice machine.

13.Use electrical tape to seal suction line insulation.

14. Reattach the wiring harness to the compressor.

15.Replace the filter/dryer before evacuating the machine. Make sure that filter/dryer tubing is not rubbing against the compressor.

16.Evacuate machine to 500 microns.

17.Charge the machine with nameplate charge.

18.Make sure that all tubing is not rubbing against anything else in the machine.

19.Reinstall corner post that was removed earlier and place electrical cover on compressor.

20.Reinstall back panels of ice machine.

C. Return to instruction #11. | 8006173 |

| Sheet 2 of 3 |

| 06/25/01 |