S600M specifications

The Manitowoc Ice S600M is a standout model in the ice machine market, recognized for its high performance, innovative features, and reliability. Designed specifically for restaurants, bars, and various foodservice operations, this ice machine offers a range of capabilities that cater to the diverse needs of commercial establishments.One of the key features of the Manitowoc S600M is its impressive ice production capacity. It can produce up to 550 pounds of ice in a 24-hour period, making it suitable for busy environments where high volumes of ice are needed. The machine utilizes a modular design, allowing it to work seamlessly with different storage bins and provides flexibility in placement.

The S600M is equipped with advanced technologies that enhance efficiency and ease of use. One notable technology is the Smart LED lighting, which ensures users can easily monitor and maintain the equipment. This smart feature provides real-time indications regarding the ice production process, alerting operators to issues such as water supply problems or the need for maintenance.

Another significant aspect of the S600M is its energy efficiency. The machine is designed with innovative insulation that minimizes temperature fluctuations, thereby reducing energy consumption. This not only contributes to lower operational costs but also aligns with environmentally friendly practices—a crucial consideration for modern businesses.

In terms of the ice itself, the Manitowoc S600M produces traditional cube-shaped ice, known for its slower melting rate and ideal for various drinks and cocktails. This type of ice is essential for maintaining beverage quality over extended periods, making it a popular choice among foodservice operators.

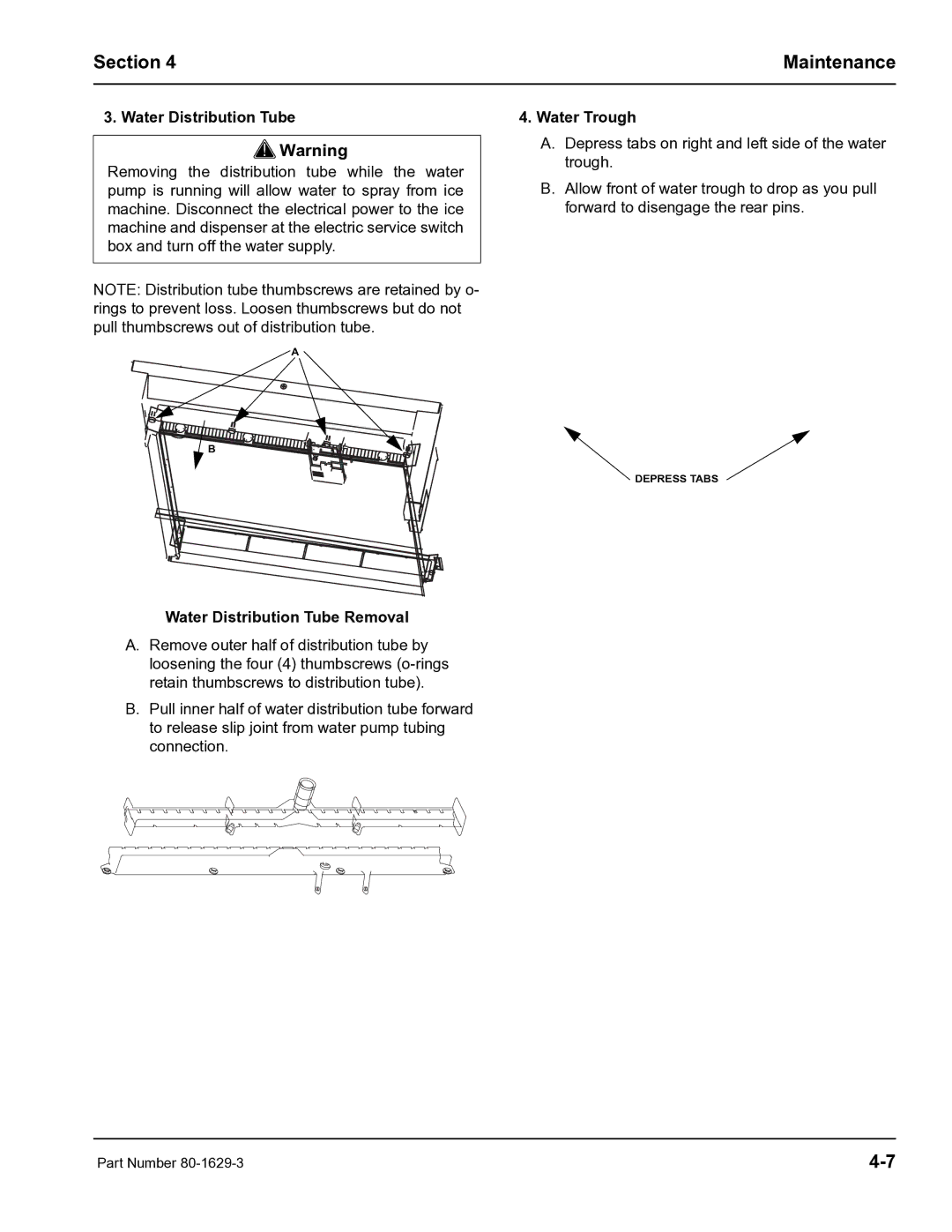

The machine is also designed with ease of maintenance in mind. It features a self-contained refrigeration system and removable panels, allowing for easy access to internal components. This design minimizes downtime and facilitates regular cleaning and maintenance, ensuring consistent ice production.

In summary, the Manitowoc Ice S600M is an exceptional choice for businesses seeking a reliable and efficient ice machine. With its high production capacity, advanced technologies, energy efficiency, and user-friendly design, it meets the contemporary demands of the foodservice industry. Investing in the S600M means ensuring an uninterrupted supply of quality ice, essential for exceptional customer service and operational success.